Alcohol crossed circle manufacturing technique with potatoes as the main materials

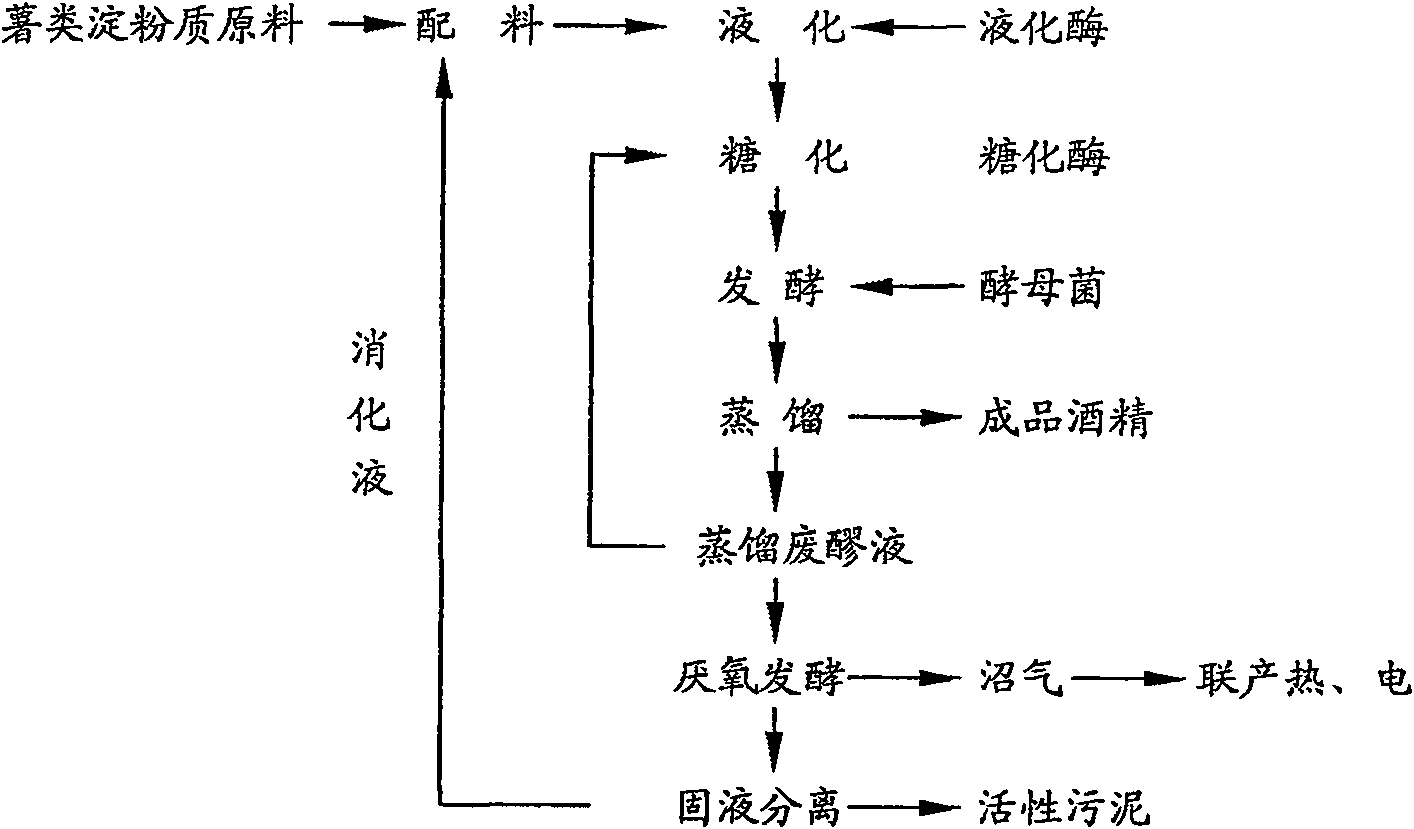

A production process, a double-circle technology, applied in biofuels, fermentation, etc., can solve the problems of liquefied enzymes not working normally, not using industrial production scale, and high-concentration wastewater discharge, so as to reduce investment in fixed assets and eliminate inhibition. , to achieve the effect of zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention uses potatoes as the main raw material for the alcohol double ring production process to adopt the following process steps:

[0025] Take 100g of sweet potato powder, add 200ml of the previous batch of anaerobic fermentation digestion liquid, add 0.07ml of high-temperature-resistant α-amylase, stir evenly and heat, keep warm at 95°C for 60 minutes to liquefy; quickly cool down to 58°C, add the previous batch of distillation waste mash 100ml, add 0.15ml of glucoamylase (common commercial glucoamylase) after mixing, keep saccharification at 62°C for 0.5hr, cool down to 30°C after saccharification, add 10% expanded alcoholic yeast, and ferment at constant temperature for 64hr; The volume of the mature fermented liquid is 343ml, and the alcohol concentration is 9.2% (v / v); 32ml (95.2% v / v) of finished alcohol is obtained through distillation and 310ml of distilled waste mash is obtained. Take out 100ml of waste mash as water for the next batch of sacch...

Embodiment 2

[0027] The present invention uses potatoes as the main raw material for the alcohol double ring production process to adopt the following process steps:

[0028] Take 2000g of cassava flour, add 4000ml of the previous batch of anaerobic fermentation digestion liquid, add 1.2ml of high-temperature-resistant α-amylase, stir evenly and heat, keep warm at 95°C for 50 minutes to liquefy; quickly cool down to 62°C, add the previous batch of distillation waste mash 2000ml, add 2.4ml of glucoamylase (common commercial glucoamylase), keep saccharification at 62°C for 0.5hr, cool down to 30°C after saccharification, add 8% expanded alcoholic yeast to ferment at constant temperature, and ferment for 60hr; after fermentation, mature fermentation The liquid volume is 6850ml, and the alcohol concentration is 11.9% (v / v); 740ml (96% v / v) of finished alcohol is obtained through distillation, and 6200ml of distilled waste mash is obtained. Set aside 2000ml of waste mash as water for the next b...

Embodiment 3

[0030] The present invention uses potatoes as the main raw material for the alcohol double ring production process to adopt the following process steps:

[0031] Take 9000kg of cassava flour and add 24m of the last batch of digestive juice 3 , add 3.2 liters of high-temperature-resistant α-amylase, stir evenly and heat, liquefy at 95°C for 60 minutes; quickly cool down to 65°C, add 4m of the previous batch of distilled waste mash 3 , add 9 liters of glucoamylase (common commercial glucoamylase), keep saccharification at 62°C for 0.45hr, cool down to 28°C after saccharification, insert 8% expanded alcoholic yeast for fermentation, and ferment for 66hr; after fermentation, the volume of mature fermentation liquid is 35.6m 3 , the alcohol concentration is 10.3% (v / v); the finished alcohol 3040L (96% v / v) is obtained by distillation, and the distillation waste mash is 32.6m 3 , through the sedimentation tank to separate the mud and sand, leaving 4m 3 The waste mash is used as w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com