Flash evaporation ferment method of synchronous gas stripping for producing ethanol

A fermentation method and ethanol technology, applied in fermentation, biofuels, etc., can solve problems such as difficulty in finding high selectivity, low ethanol removal efficiency, membrane fouling, and low flux, to eliminate substrate inhibition and enhance ethanol in The effect of bit extraction ability and improvement of fermentation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

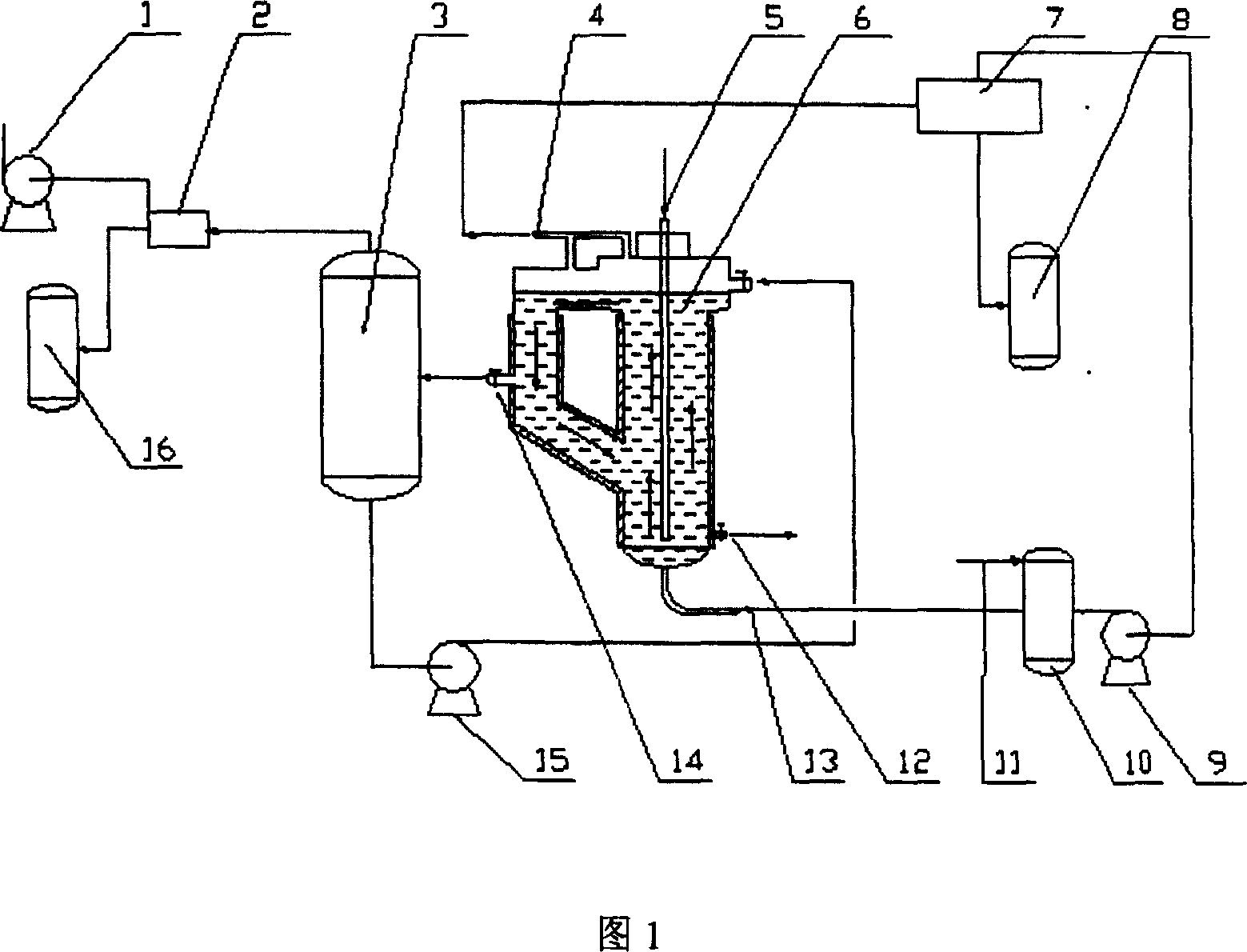

[0011] As shown in Figure 1, add the saccharified mash into the fermenter with side arms, the glucose content is 250g / L, and the yeast is connected to start the fermentation, the inoculum is 4g / L, the temperature is maintained at 32℃, and a small amount of CO is introduced. 2 , The aeration volume is 0.01m per liter of fermentation broth 3 / h. After 18 hours of fermentation, the ethanol concentration reached 60g / L, open the valve between the fermentation tank and the flash tank, increase the ventilation, and start the simultaneous stripping flash operation. CO 2 The aeration volume is 0.1m per liter of fermented mash 3 / h, the pressure of the flash tank is maintained at 38mmHg, and the flow rate into the flash tank is 10ml / min per liter of fermentation mash. Through CO 2 The ethanol and water taken out are recovered by the condenser, and the concentration is above 40% (mass concentration). The fermented mash enters the flash tank from the fermenter, the vapor phase obtained by fla...

Embodiment 2

[0013] The conditions for the start of fermentation are the same as in Example 1. When the simultaneous stripping and flashing operation is started, the feed valve is opened and the feed is started to realize continuous fermentation, as shown in FIG. 1. The feeding rate is 24ml / h per liter of mash, and the feeding glucose concentration is 500g / L. High-concentration feed can save water. During the continuous fermentation process, the concentration of ethanol was maintained at 55g / L, the concentration of glucose was maintained at 80g / L, and the cell concentration was maintained at 10g / L. The fermentation intensity can reach 5.5g -1 h -1 , Which is 3 times of normal fermentation under the same fermentation conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com