Measuring method and device for fiber material transverse compression property

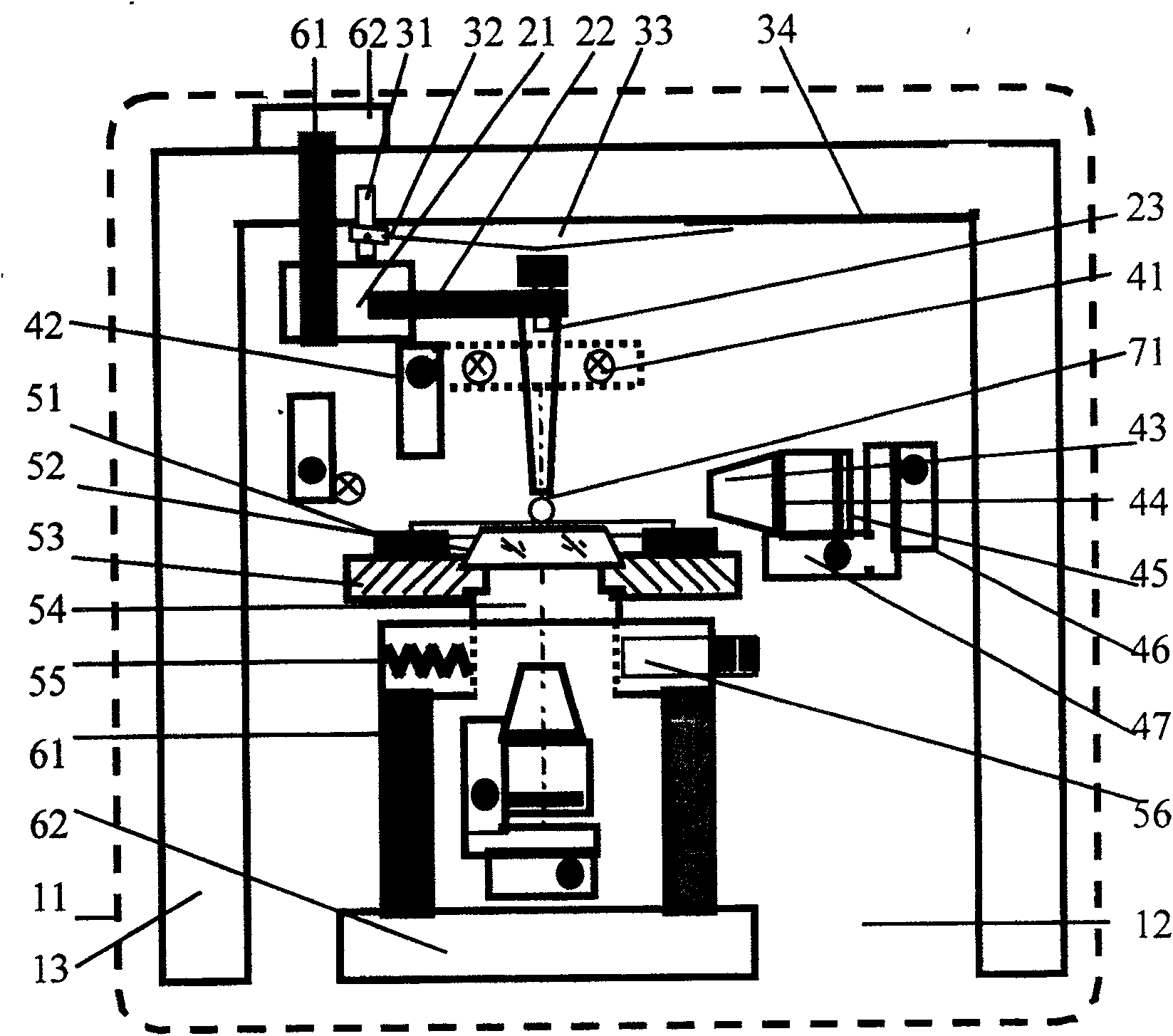

A technology of transverse compression and measurement method, which is applied in the field of micro-measurement, can solve the problems of small transverse compression displacement of fibers, reduction of fiber layer thickness, increase of fiber contact area, etc., and achieves reduction of measurement error, accurate and convenient adjustment, and device structure compact design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following practical operations and examples will help to understand the present invention, but do not limit the content of the present invention.

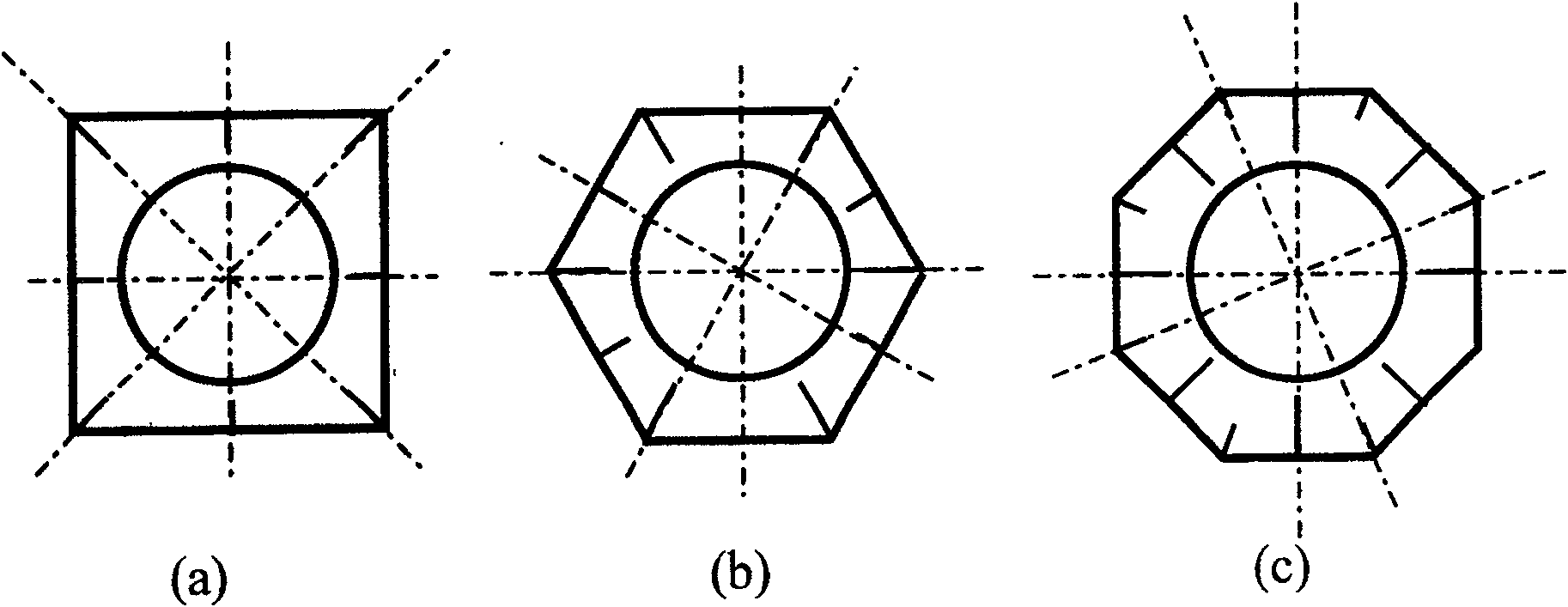

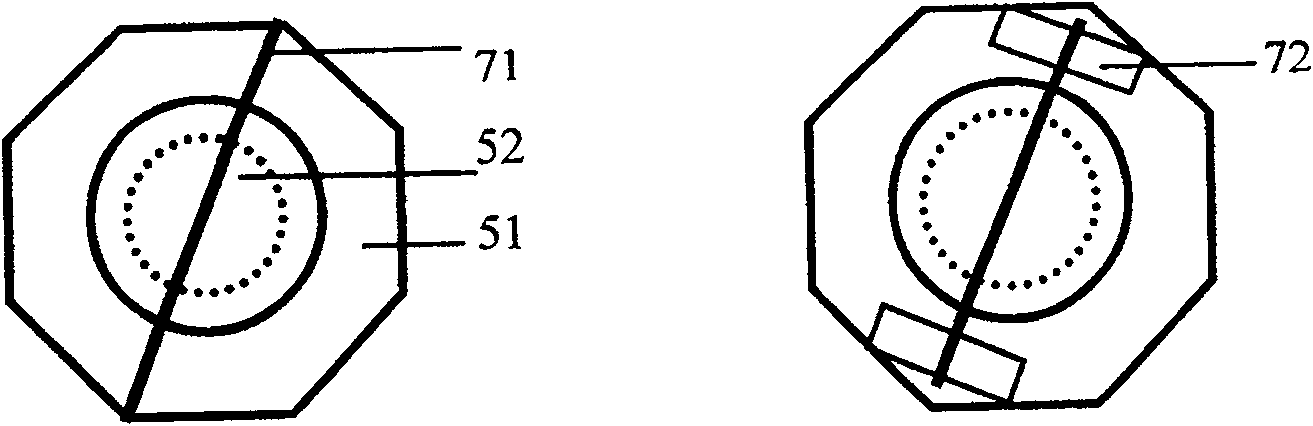

[0064] a) Typical measurement operation, first prepare the fiber layer sample, take out the single fiber from the fiber bundle, and wind it on the polygonal disc 51, the central hole of the polygonal disc is a hollow circle with a diameter of 2 to 3 cm, such as figure 2 As shown, it can be a square disc, a hexagonal disc, an octagonal disc, etc., the fibers are straightened along the diagonal or opposite sides, and the double-sided adhesive tape 72 is attached to fix it. image 3 Cut the fiber at a certain angle at the dotted line in the middle, and use the angle positioning function of the octagonal disc to complete the precise angle overlapping fiber positioning such as Figure 4 , the fibers are at an angle of θ (0° to 90°) overlapping angle sample 73, a sample 74 with multiple fibers arranged at intervals such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com