Coupled apparatus used between heat phonomotor and refrigerating device driven by the same

A technology of thermoacoustic engine and coupling device, which is applied in the direction of hot gas variable volume engine device, refrigerator, machine/engine, etc., can solve the problems of low efficiency, consumption of helium, and poor refrigeration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

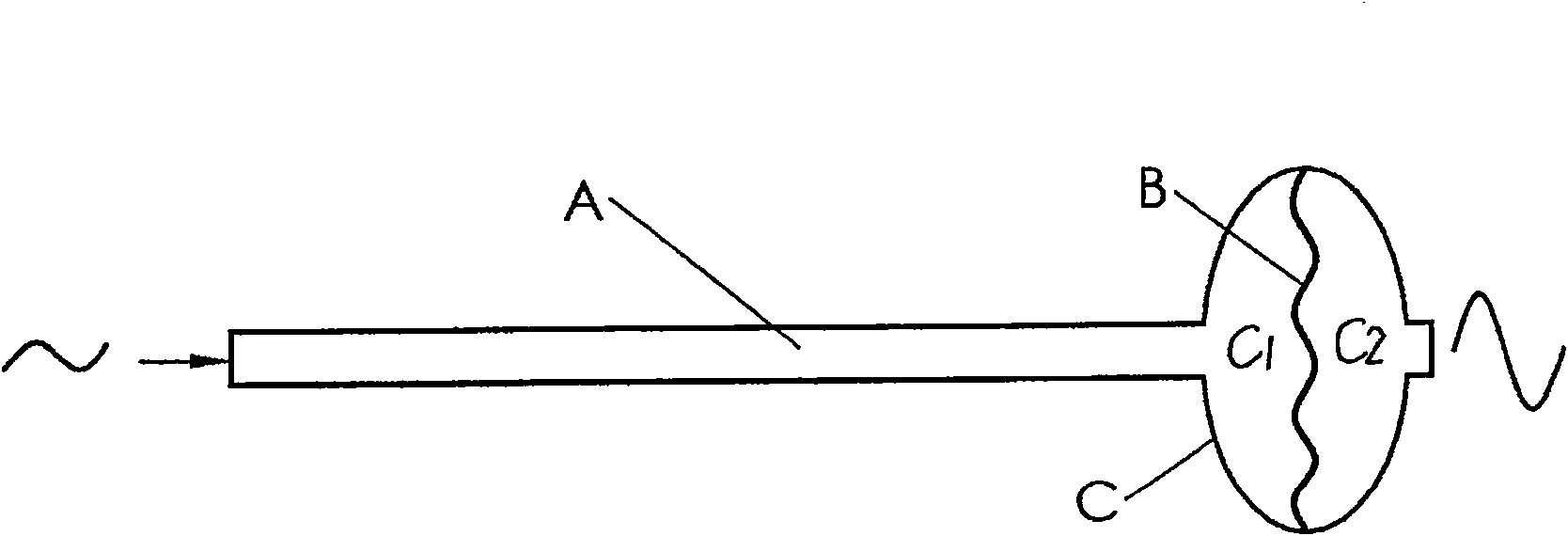

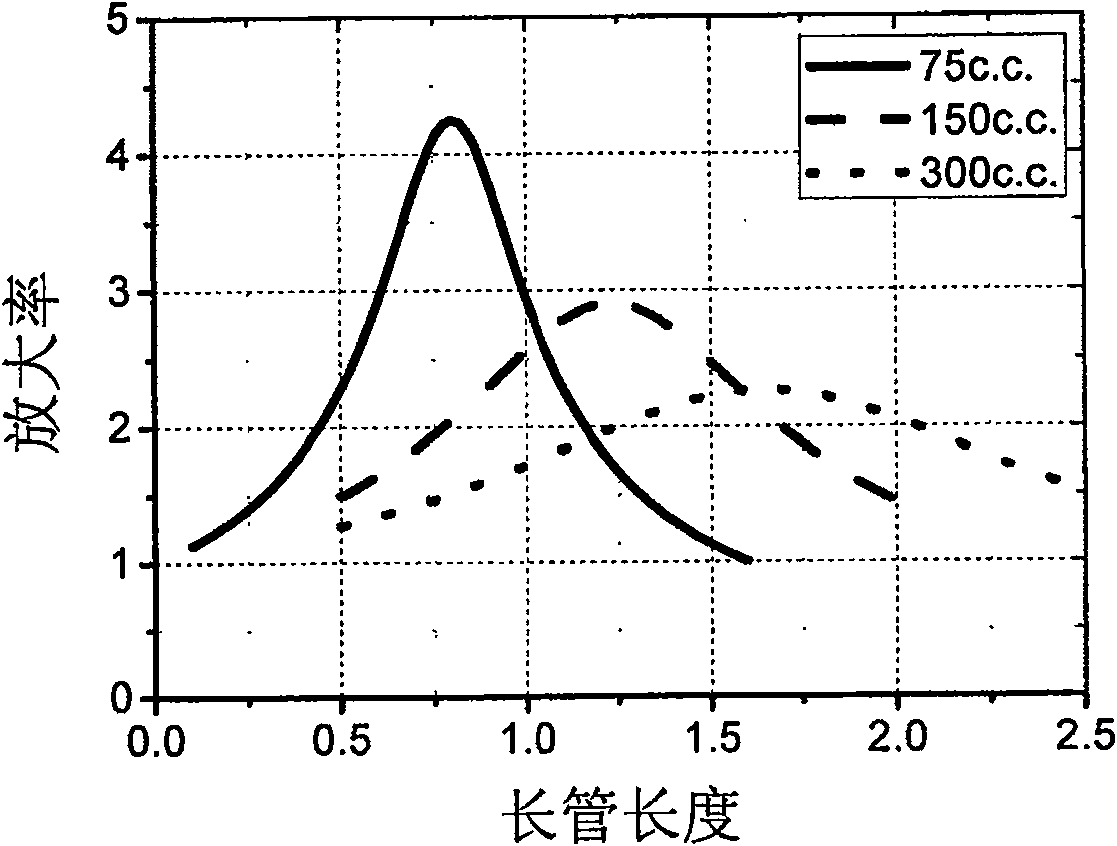

[0053] Embodiment 1: adopt Figure 5 The coupling device shown; the coupling device includes: a cavity C;

[0054] An elastic diaphragm B installed in the cavity C, the elastic diaphragm B divides the cavity C into a first chamber C1 and a second chamber C2;

[0055] A long tube A connected to the side wall of the cavity C and communicated with the first chamber C1;

[0056] A short tube F communicating with the other side wall of the cavity C and communicating with the second chamber C2;

[0057] The other end of the long pipe A is communicated with the feedback pipe 12 of the thermoacoustic engine through the ball valve 1;

[0058] The other end of the short pipe F communicates with the water cooler 21 of the refrigerator.

[0059] The engine is a traveling wave thermoacoustic engine (marked with D), and the traveling wave thermoacoustic engine is composed of the first water cooler 2 of the engine, the regenerator 3 of the engine, the heater 4 of the engine, the heat buffer...

Embodiment 2

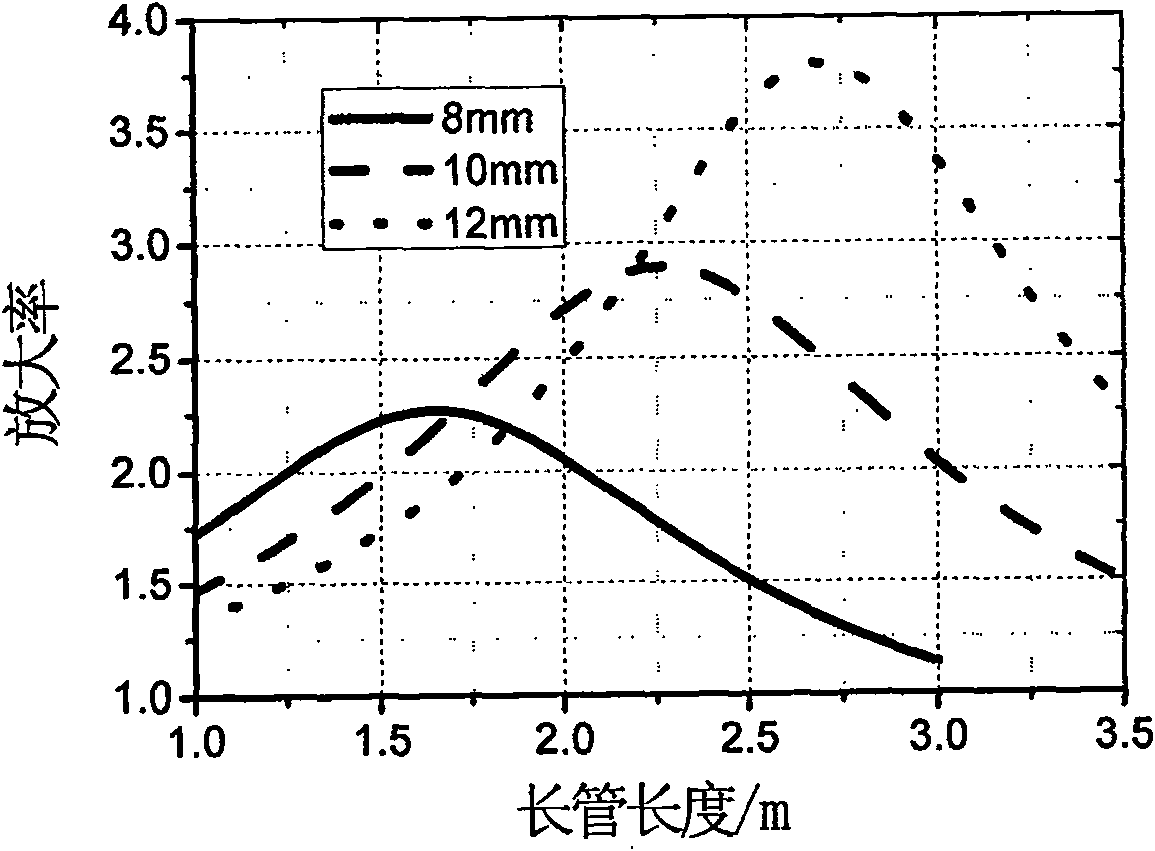

[0061] Embodiment 2: adopt Figure 6 The structural device shown. The size of the engine D is the same as that of the engine in Embodiment 1; the length of the long pipe A in the coupling device is 1.6m, and the diameter is 17mm, and it communicates with the engine at the junction of the annular ring formed by the various parts of the engine and the resonant tube 13; the cavity The structure and size of C are the same as the cavity in Example 1. The area of the elastic film B in the cavity C perpendicular to the flow direction of the working medium is about 50 times that of the cross section of the long tube A; the refrigerator is U-shaped. Two-stage pulse tube refrigerator; the primary regenerator 31 of the refrigerator is 80 mm long and 30 mm in diameter; the secondary regenerator 32 of the refrigerator is 80 mm long and 12 mm in diameter; the primary pulse tube 10 of the refrigerator is 104 mm long and 12 mm in diameter; The secondary pulse tube 101 is 160 mm long and 8 ...

Embodiment 3

[0062] Embodiment 3: adopt Figure 7 The structural device shown. The engine is a standing wave thermoacoustic refrigerator. The total length of the thermal cavity, heater, regenerator and water cooler is 238mm, and the diameter is 100mm. The resonance tube consists of a tapered tube with a length of 3m and a diameter ranging from 100mm to 200mm, and a straight tube with a diameter of 200mm at one end and a length of 0.5m. The long pipe A in the coupling device has a length of 1m and a diameter of 50mm, and communicates with the engine through a ball valve. The elastic diaphragm is a 1 mm thick nitrile rubber film.

[0063] The diameter of the elastic membrane B in the cavity C is 120 mm, and its area perpendicular to the flow direction of the working medium is about 5 times that of the long tube A, and the total height of the cavity C is 100 mm. The refrigerator is a thermoacoustic refrigerator, the total circumference of the annular ring is 1.2m, the diameter of the feedb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com