Coating for concrete for maintenance and protection and its preparation and usage method

A technology for concrete and coatings, applied in the field of building materials, can solve the problems of not being able to use concrete structures for early maintenance, only considering the waterproof function, and not considering the corrosiveness of sulfate to coatings, etc., so as to prevent water loss, simple preparation process and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

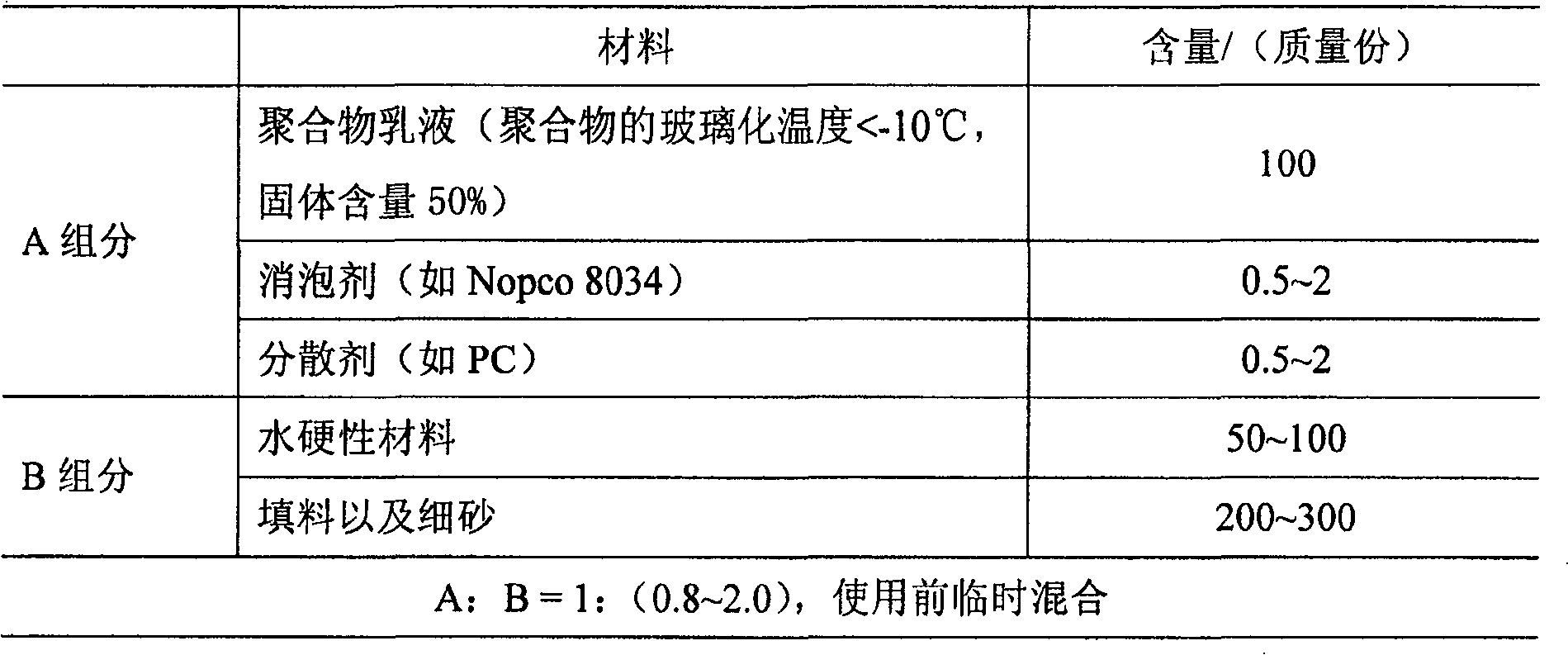

Method used

Image

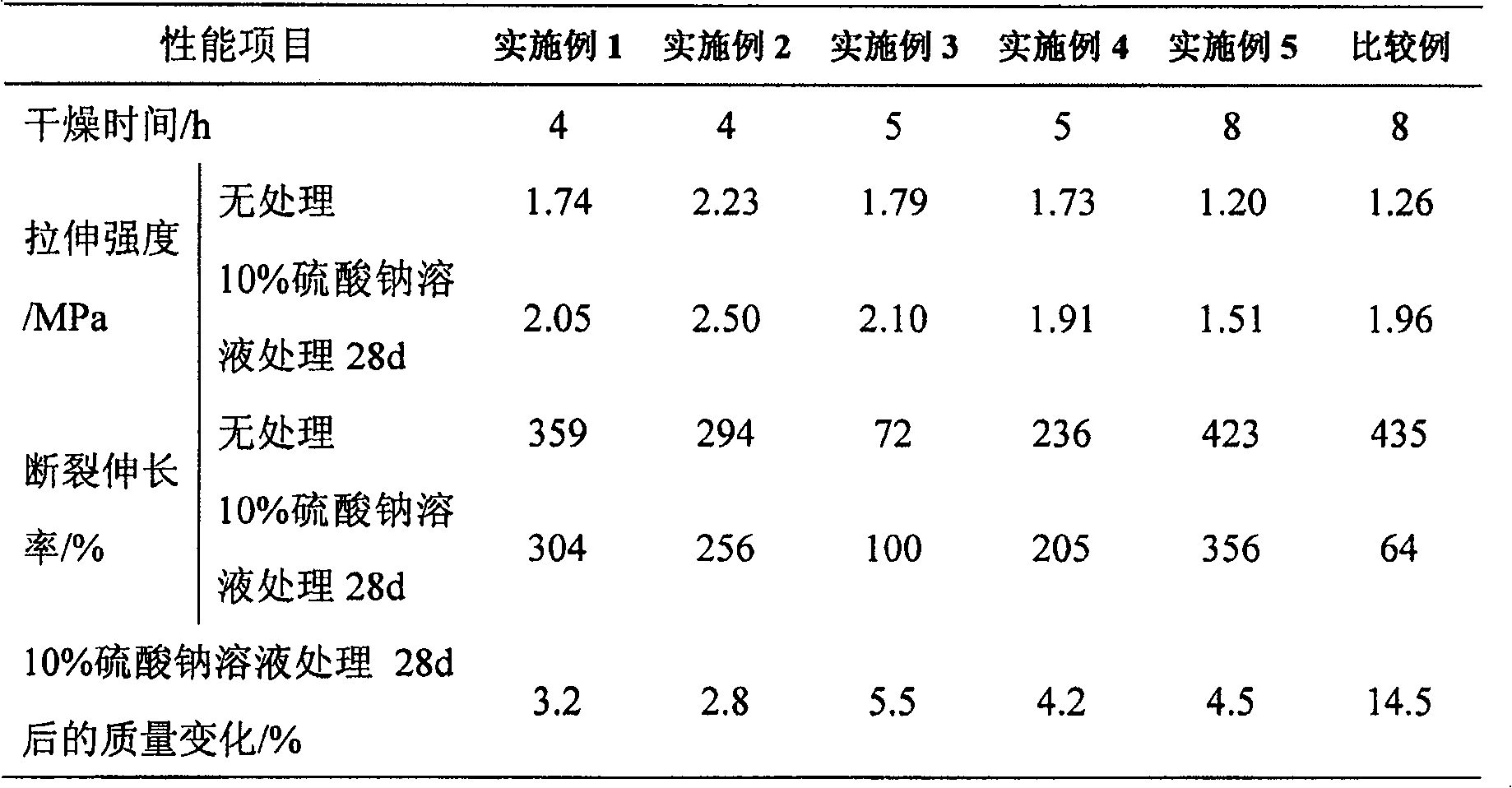

Examples

Embodiment 1

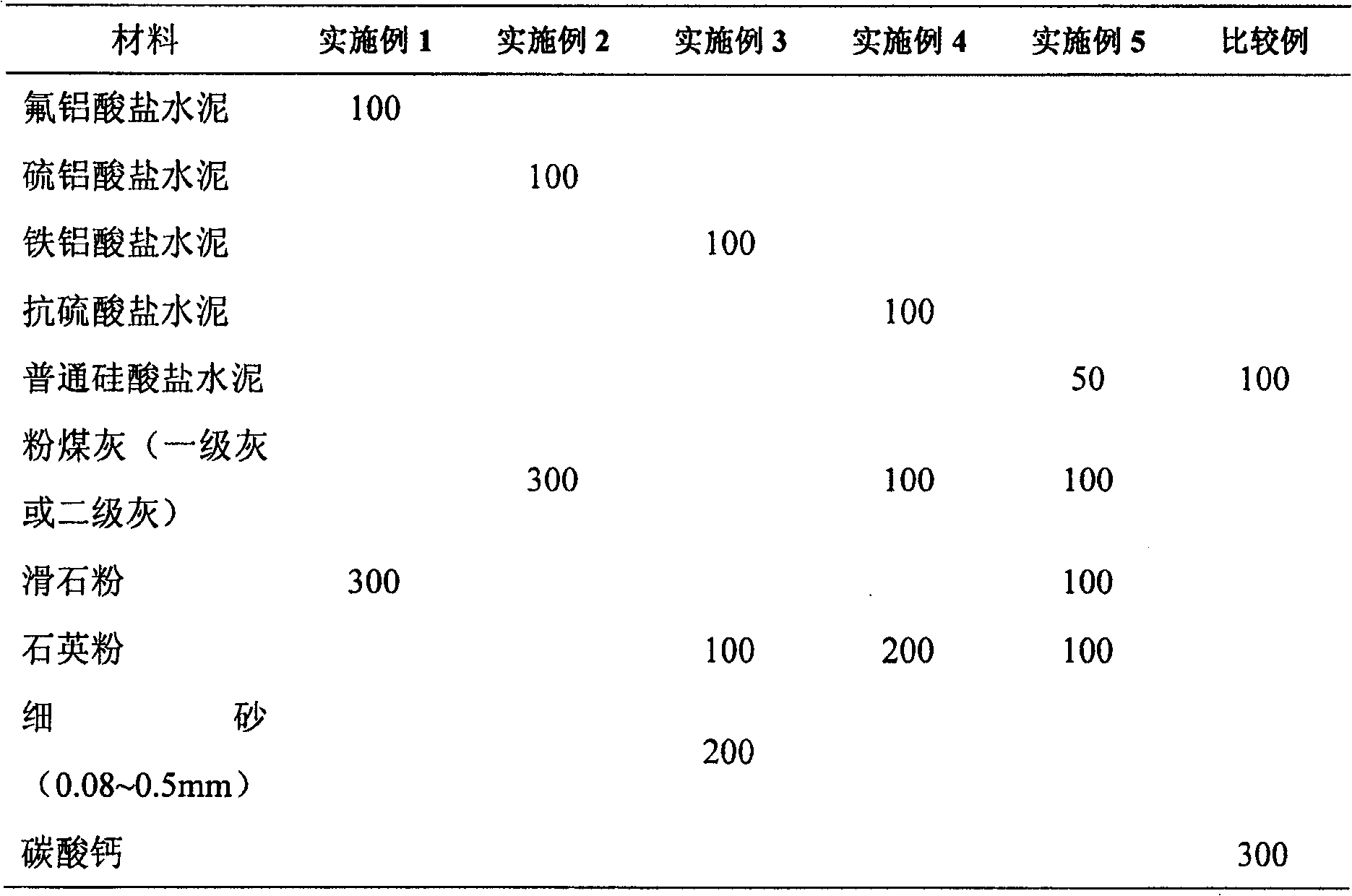

[0024] In this example, fluoroaluminate cement is used as the hydraulic cementitious material. The main hydration products of fluoroaluminate cement are trisulfide-type calcium sulfoaluminate hydrate, hydrated alumina gel and calcium silicate hydrate, which have outstanding sulfate resistance. The filler is talcum powder, and quartz powder can also be used. Since the fluoroaluminate cement is a block-setting rapid-hardening cement, although the polymer emulsion has a certain retarding effect, it is still possible to add (0.2-0.3)% boric acid of cement quality as a retarder if necessary.

[0025] The mass ratio of A and B components is A:B=1:1.

[0026] Table 2 The formula of B component in various embodiments

[0027]

Embodiment 2

[0029] In this example, sulfoaluminate cement was used as the hydraulic binder. The main hydration products of sulfoaluminate cement are trisulfide calcium sulfoaluminate hydrate and monosulfide hydrate sulfoaluminate, hydrated alumina gel and hydrated calcium silicate gel. It has good resistance to sulfate attack.

[0030] The mass ratio of A and B components is A:B=1:0.8.

Embodiment 3

[0032] In this example, aluminate ferrite cement was used as the hydraulic binder. Aluminoferric cement has good resistance to sulfuric acid. Using quartz powder and fine sand as fillers can make the paint more breathable.

[0033] The mass ratio of A and B components is A: B=1:1.6

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com