Preparation method of solid polycarboxylate superplasticizer

A technology of polycarboxylic acid and water reducing agent, applied in the field of polycarboxylic acid water reducing agent, can solve the problems of decreased activity frequency, hindered rearrangement of chain segments and chain segments, low production efficiency, etc., and achieves improved molecular adsorption capacity and improved Production effect and overall efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

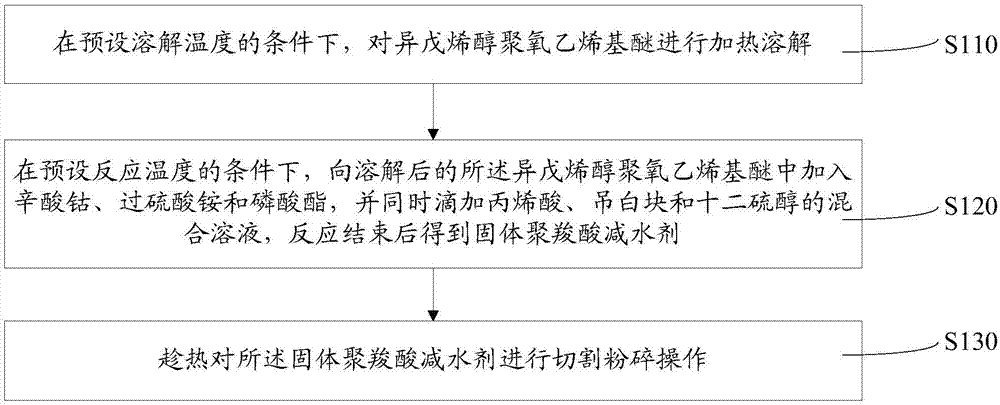

[0021] see figure 1 , the preparation method of solid polycarboxylate water reducer in one embodiment, comprises the steps:

[0022] S110: Under the condition of preset melting temperature, heat and melt the prenol polyoxyethylene ether.

[0023] By heating and melting the prenol polyoxyethylene ether under the preset melting temperature, a colorless and transparent liquid prenyl polyoxyethylene ether can be obtained, which is convenient for subsequent mixing with other components reaction. Isopentenol polyoxyethylene ether is used as a monomer of polycarboxylate water reducer to participate in polymerization reaction.

[0024] S120: Add cobalt isooctanoate, ammonium persulfate and phosphoric acid ester to the melted isopentenol polyoxyethylene ether under the condition of preset reaction temperature, and simultaneously add acrylic acid, chrysanthemum block and ten A mixed solution of dithiol, after the reaction, a solid polycarboxylate water reducer is obtained.

[0025] ...

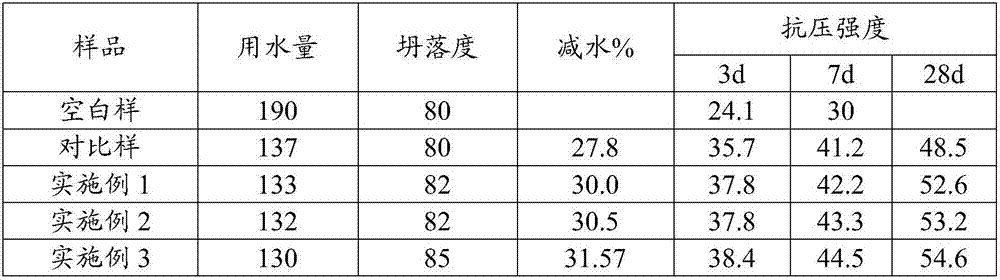

Embodiment 1

[0038] Put 240g (prenyl alcohol polyoxyethylene ether) TPEG into the reaction kettle, raise the temperature to 75°C-80°C, wait until the TPEG is completely melted, turn the temperature back to 65°C-70°C, add 0.36g iso Cobalt octoate, 2.1g ammonium persulfate, 25g phosphoric acid ester, stir well, add dropwise 16g of acrylic acid solution, 1.2g of dodecyl mercaptan and 0.54g of white block solution, react for 4 hours, keep warm for 1 hour, and pour it out while the reaction is over out.

Embodiment 2

[0040] Put 240g of TPEG into the reaction kettle, raise the temperature to 75°C-80°C, wait until the TPEG is completely melted, turn the temperature back to 65°C-70°C, add 0.42g of cobalt isooctanoate, 2.8g of ammonium persulfate, and 25g of phosphoric acid ester , fully stirred evenly, and at the same time, dropwise added a mixed solution of 20g of acrylic acid solution, 1.4g of dodecyl mercaptan and 0.64g of basil, reacted for 4 hours, kept it warm for 1 hour, and poured it out while the reaction was over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com