Polycarboxylate copolymer, preparation method thereof and polycarboxylic acid water reducing agent containing polycarboxylate copolymer

A technology of polycarboxylate and copolymer, applied in the field of polycarboxylate copolymer and preparation method thereof, and polycarboxylate water reducer containing the same, can solve unmentioned application conditions, poor workability, slump In order to improve the adaptability and slump retention performance, improve the molecular adsorption capacity, and delay the hydration of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

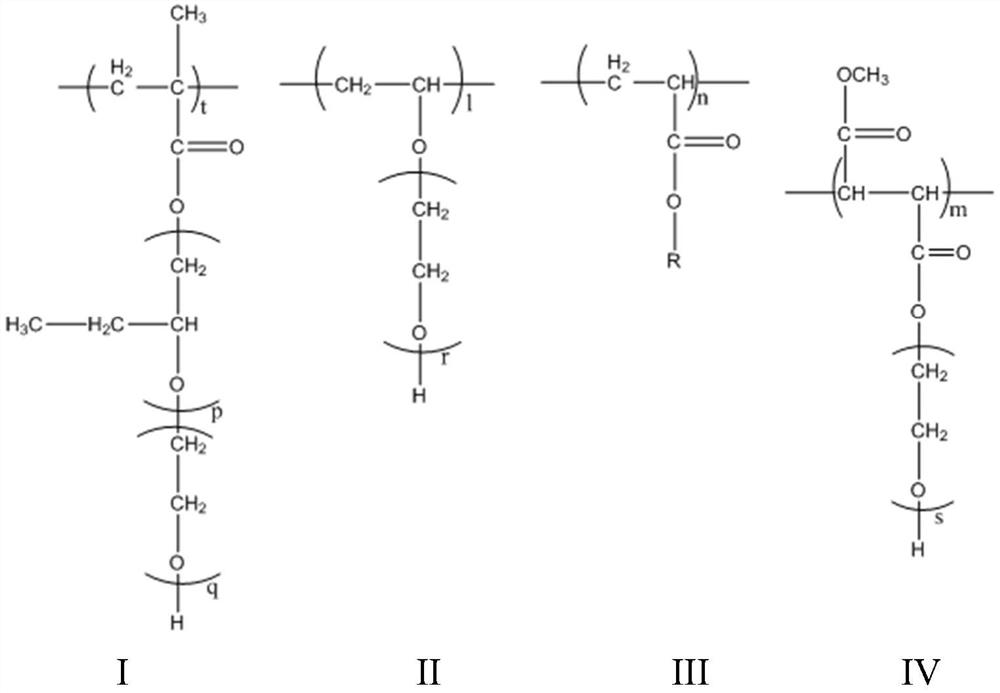

Method used

Image

Examples

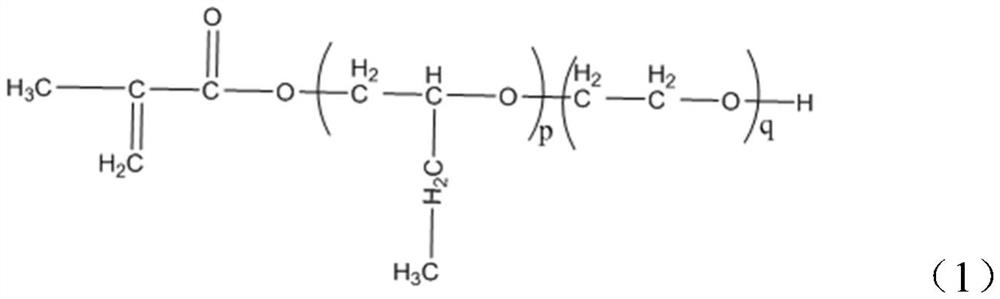

preparation example 1

[0131] The preparation method of the functional polyether monomer is as follows: adding methacrylic acid, hydroquinone and calcium acetate into the reactor, performing nitrogen replacement three times, stirring and heating up, and adding a small amount of butylene oxide when the temperature in the reactor reaches 80°C, When the reaction pressure drops, the remaining butylene oxide and ethylene oxide are added steadily again, keeping the pressure in the reactor at 0.3-0.5MPa, the reaction temperature at 80-120°C, and the butylene oxide and ethylene oxide. After all the additions were completed, it was kept for 0.5 hours, and then the temperature was lowered to room temperature to obtain a functional polyether macromonomer: methacrylic acid polyoxybutylene polyoxyethylene ether. The mass ratio of each material is methacrylic acid: butylene oxide: ethylene oxide: calcium acetate: hydroquinone=1:3.349:10.767:0.151:0.01. The hydroxyl value of the test product is: 44.1, the iodine v...

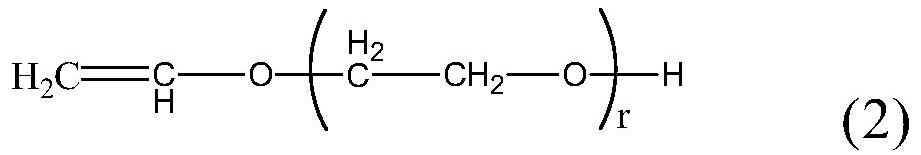

preparation example 2

[0133] The preparation method of functional small monomer is as follows:

[0134] (1) Add maleic anhydride, KOH and p-hydroxyphenol into a three-necked flask and heat up to 80-100°C, gradually add methanol dropwise in a ratio of 1:1, mature for 2-3h after the dropwise addition, and distill under reduced pressure at 80°C The unreacted methanol was discharged, and the substance in the three-necked flask was product C; the acid value of the test product C was 431.44, and the conversion rate of maleic anhydride was calculated: 100%.

[0135]

[0136] (2) Add product C, phenothiazine and potassium acetate into the reactor, carry out nitrogen replacement three times, stir and heat up, when the temperature in the reactor reaches 140 ° C, add a small amount of ethylene oxide, when the reaction pressure drops, the stable temperature again Add the remaining ethylene oxide, keep the pressure in the reactor at 0.3-0.5 MPa, and the reaction temperature at 140-180 ° C. After all the ethy...

Embodiment 1

[0138] (1) 340g of vinyl polyoxyethylene ether monomers with molecular weight of 3000 and 340g of deionized water are dropped into a four-necked flask, and the temperature is raised to 30°C for subsequent use;

[0139] (2) Prepare material a and mix it evenly. Material a consists of 0.997g vitamin C, 0.901g mercaptopropionic acid and 58.90g deionized water; prepare material b and mix it evenly. of functional polyether monomer and 38.40g deionized water;

[0140] (3) Add 2 g of hydrogen peroxide with a mass concentration of 28% to the four-necked flask at one time, and add 3.61 g of functional small monomers of Preparation Example 2 at one time;

[0141] (4) After stirring for 2-3 minutes, add material a and material a dropwise at the same time, material A (180±20) minutes, and material B (170±20) minutes;

[0142] (5) After the dropwise addition, the reaction was continued for (60±5) minutes.

[0143] (6) Finally, add 144.75 g of deionized water to the four-necked flask, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com