Solvent recovery method in pharmacy and solvent recovery system for implementing same

A recovery system, a technology of the pharmaceutical industry, applied in separation methods, chemical instruments and methods, boiling devices equipped with condensers, etc., can solve problems such as unfavorable steam condensation, low solvent recovery rate, waste, etc., to reduce solvent loss , reduce environmental pollution, and facilitate popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

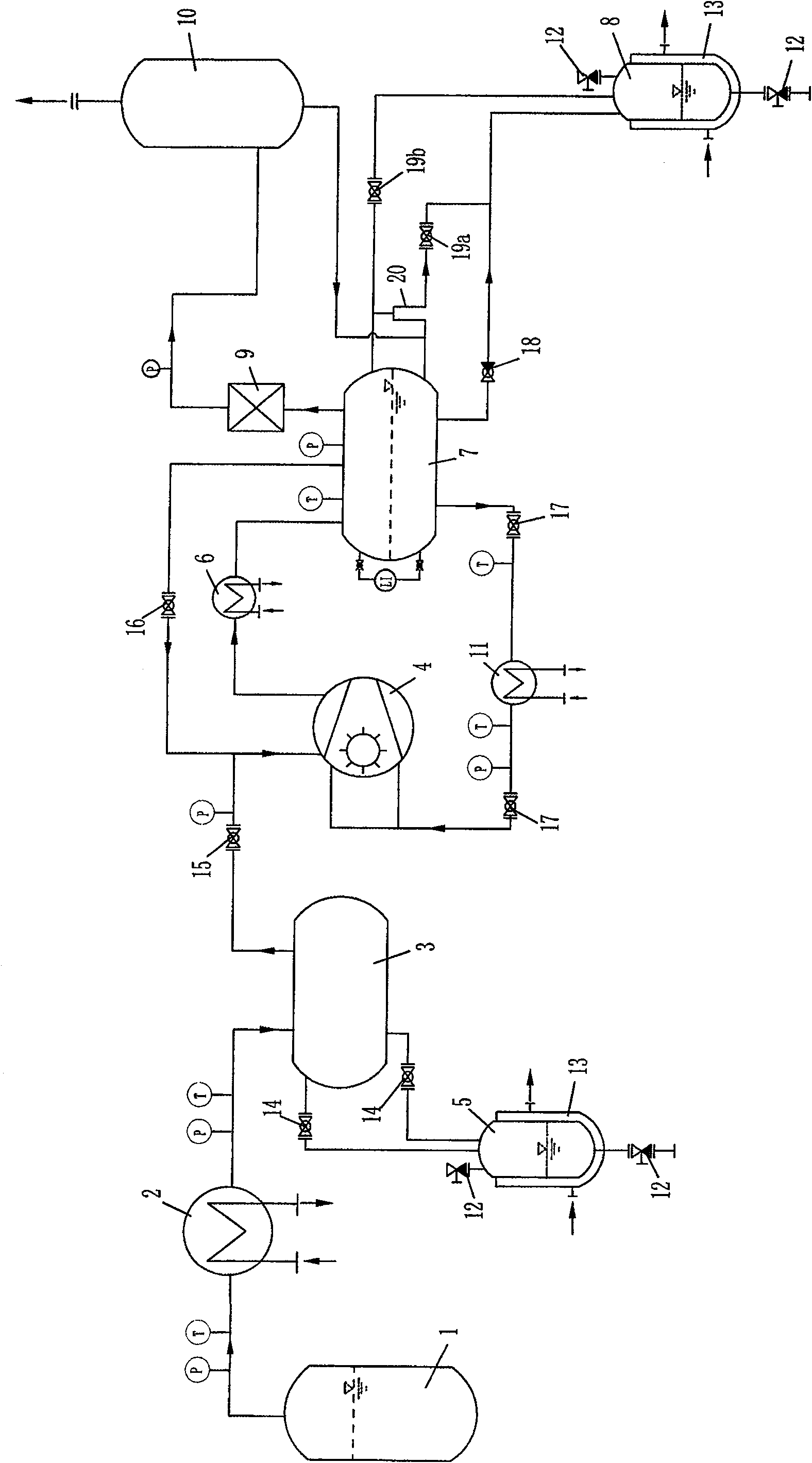

[0008] figure 1 The solvent recovery system shown can be used to practice the method of the invention. The system includes a raw material tank 1 for containing liquid medium, and a condenser 2 and a vapor-liquid separator 3 are connected in series at the steam outlet of the raw material tank 1 . The vapor outlet of the vapor-liquid separator 3 is connected to the inlet of the liquid ring pump 4 . The liquid outlet of the vapor-liquid separator 3 is connected to the recovery tank 5 . The output port of the liquid ring pump 4 is connected in series with a secondary condenser 6 and a secondary vapor-liquid separator 7. One liquid outlet of the secondary vapor-liquid separator 7 is connected to the recovery tank 8, and the other liquid outlet is connected to the liquid ring The working fluid input port of the pump 4 enables the liquid ring pump 4 to use the solvent as the working fluid. Both the condenser 2 and the secondary condenser 6 can use brine as a refrigerant. In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com