Method for preparing p-type ZnO film by doping Sb

A thin-film, p-type technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of low p-type ZnO doping efficiency, and achieve the effect of overcoming preparation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

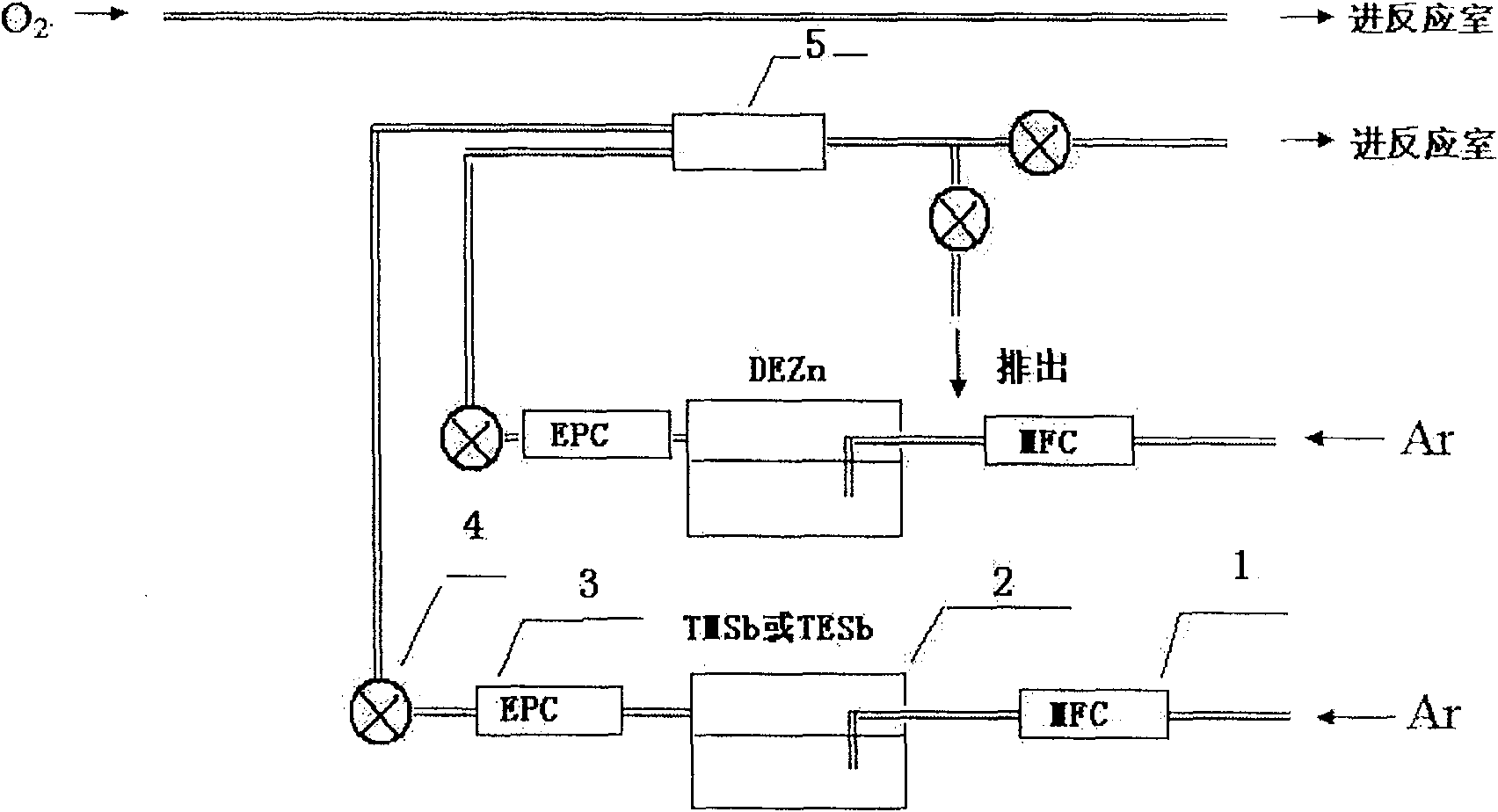

Method used

Image

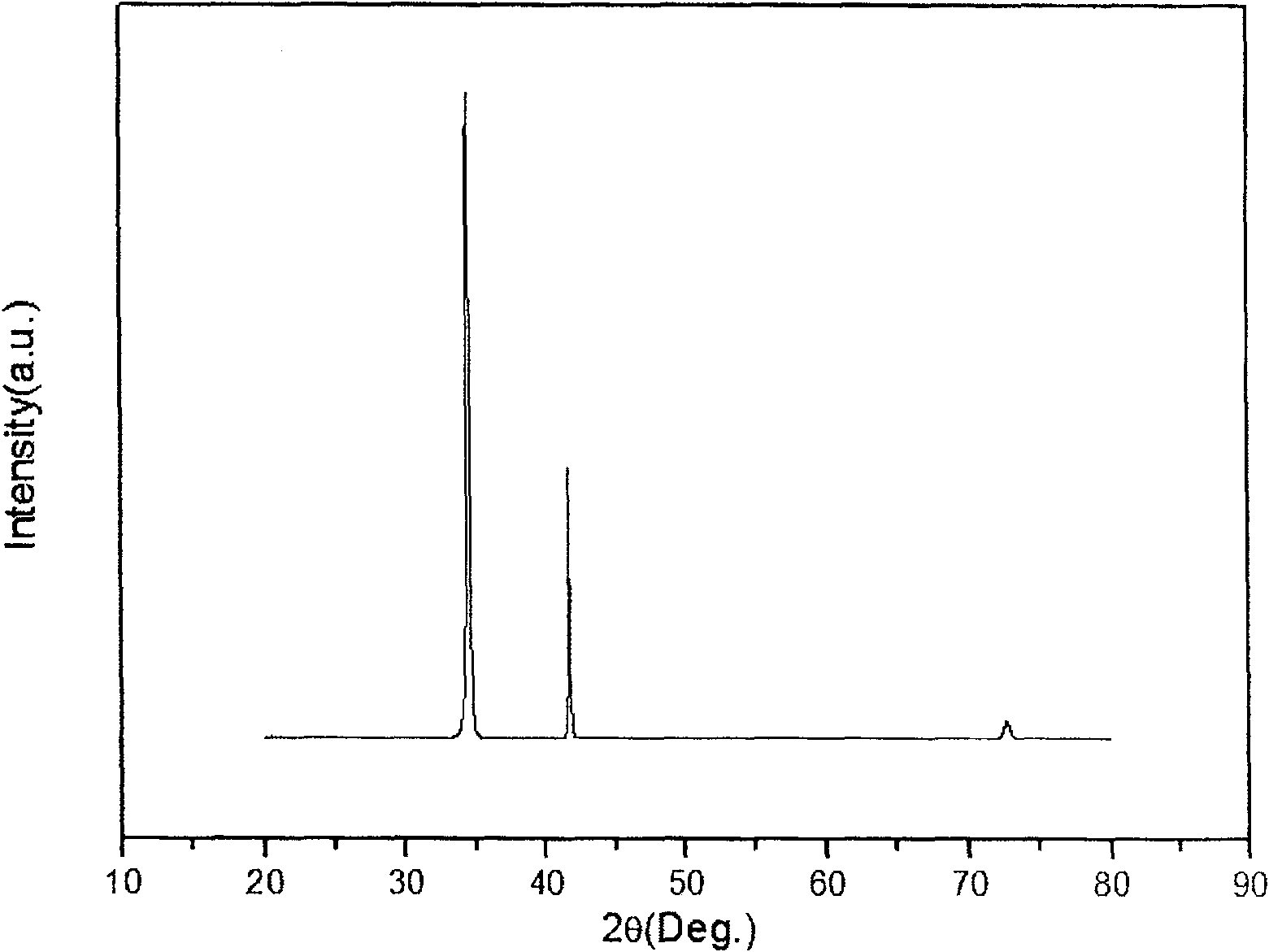

Examples

Embodiment 1

[0022] (1) Substrate cleaning treatment. Sapphire, Si, GaAs, InP, CaF for substrates 2 , Quartz, glass can be used, the substrate can be treated with the standard cleaning process of general semiconductors.

[0023] (2) Send the cleaned substrate to the pretreatment chamber, and close the door of the sample pretreatment chamber. Start the mechanical pump to evacuate the sample pretreatment chamber until the vacuum degree of the sample pretreatment chamber reaches 50-10 -1 When Pa, turn on the mechanical pump of the reaction chamber to evacuate. When the vacuum degree of the reaction chamber and the vacuum degree of the sample pretreatment chamber are basically balanced, open the connecting gate valve to transfer the substrate to the substrate sheet tray of the reaction chamber, and close the gate. plate valve.

[0024] (3) When the vacuum degree of the reaction chamber reaches below 10Pa, the turbo molecular pump of the reaction chamber can be started. The vacuum degree of...

Embodiment 2

[0030] This process method is basically the same as the steps in Example 1, the difference is that step-by-step annealing is performed during the growth process to form a buffer layer and improve the growth quality of the subsequent thin film. The specific method is to grow for a period of time at 150°C to 500°C in a low growth temperature range, 1 to 20 minutes), then turn off the zinc source, and heat the substrate sheet in situ to 700 to 800°C for thermal annealing. The treatment time is After 1 to 30 minutes, the substrate temperature is lowered to the growth temperature and then the growth is continued until the required thickness is reached.

Embodiment 3

[0032] This process method is the same as the steps in Example 1, the difference is that after the growth is completed, the zinc source is turned off, and the substrate temperature is raised to 700-800 °C and then annealed in oxygen to further improve the doping of p-type ZnO. quality; can also be used concurrently with the method of introducing a buffer layer in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com