Droplet whispering gallery mode laser and manufacturing method thereof

A technology of a whispering gallery mode and a manufacturing method, applied in the field of lasers, can solve the problems of imperfect surface, loss of solid-state microsphere cavity, complicated manufacturing process, etc., and achieve the effect of low threshold value, high Q value, and overcoming manufacturing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with examples in conjunction with the accompanying drawings.

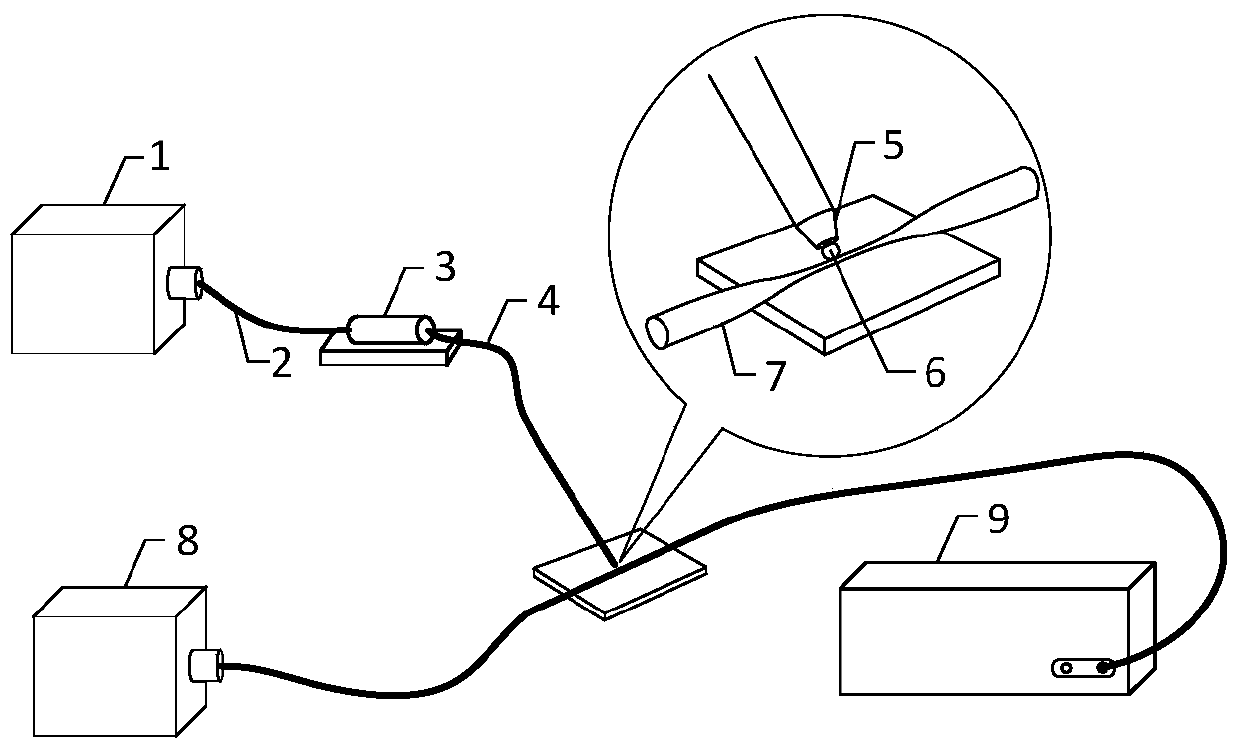

[0037] like figure 1 As shown, the droplet whispering gallery mode laser of the present invention includes a trapping light source 1, a single-mode fiber 2, a fiber coupling region 3, a ring-core fiber 4, a truncated conical fiber tip 5, a liquid crystal droplet 6 doped with a laser dye, Tapered single-mode optical fiber 7, pump light source 8, spectrometer 9.

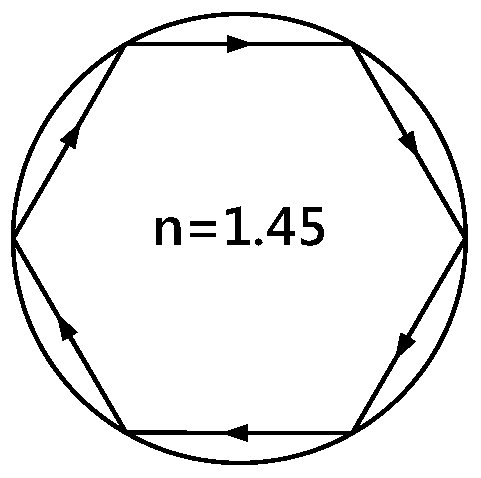

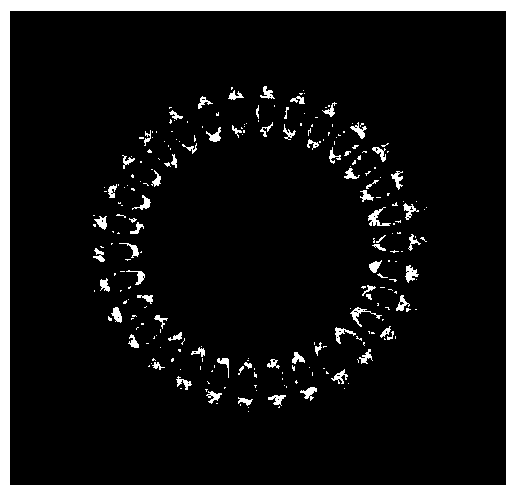

[0038] The laser beam emitted by the light source is injected into the core of the ring-core fiber through the fiber coupling region through the single-mode fiber. The light is totally reflected and refracted at the slope of the ring-core fiber’s frustum-shaped fiber tip, and forms a ring-shaped convergence near the fiber’s frustum-shaped fiber tip. The optical field realizes the function of optical tweezers. The optical tweezers are used to stably capture liquid crystal micro-droplets doped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com