Method for connecting ceramic-base inert anode used for aluminum electrolysis and metal conducting bar

An inert anode, metal conductive technology, applied in the field of stable connection between ceramic base inert anode and metal conductive rod for aluminum electrolysis, can solve the problems of poor electrical connection stability, inability to use, easy corrosion failure of the connection interface, etc., to achieve the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

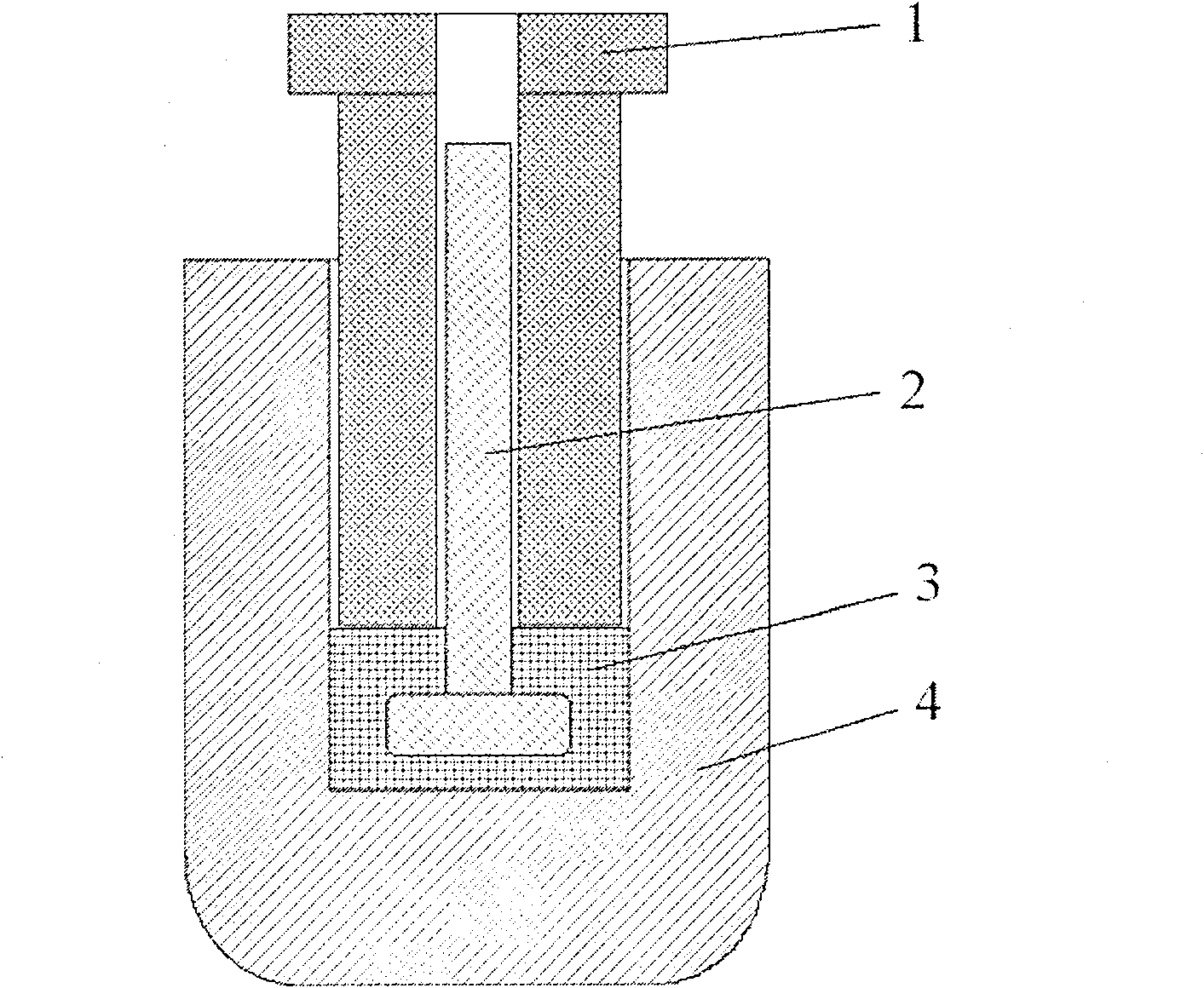

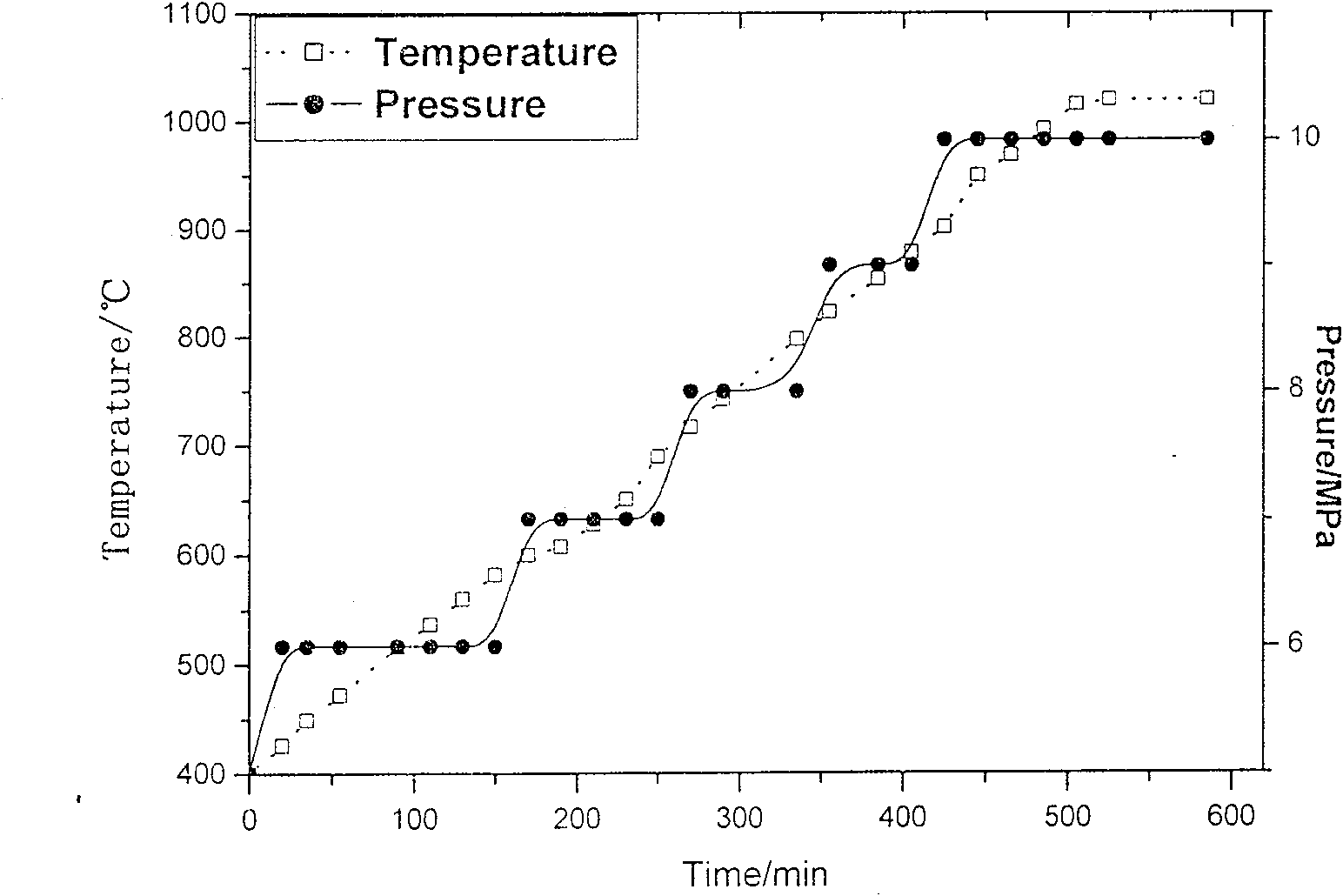

[0022] Such as figure 1 , Describes the schematic diagram of the connection process between the cup-shaped inert anode and the conductive rod. It mainly includes indenter 1, conductive rod 2, solder 3, and cup-shaped inert anode 4. The composition is NiFe 2 O 4 -10NiO / 17Ni inert anode, conductive rod material is Cr12MoV. The process of pressure diffusion welding is as follows: First, the inner surface of the cup-shaped inert anode and the outer surface of the conductive connecting rod are electrolessly plated with nickel, the thickness of the plating layer is about 120μm, and then the composition is 50wt% NiFe 2 O 4 The powder solder of +25wt%Ni+25wt%Cu is filled into the anode cup, and then the conductive rod is buried in the solder powder, and finally the indenter is placed above the solder powder to complete the assembly work. The above assembly mechanism is placed in a hot pressing furnace, the electric furnace is closed and the system is vacuumed, and when the vacuum reach...

Embodiment 2

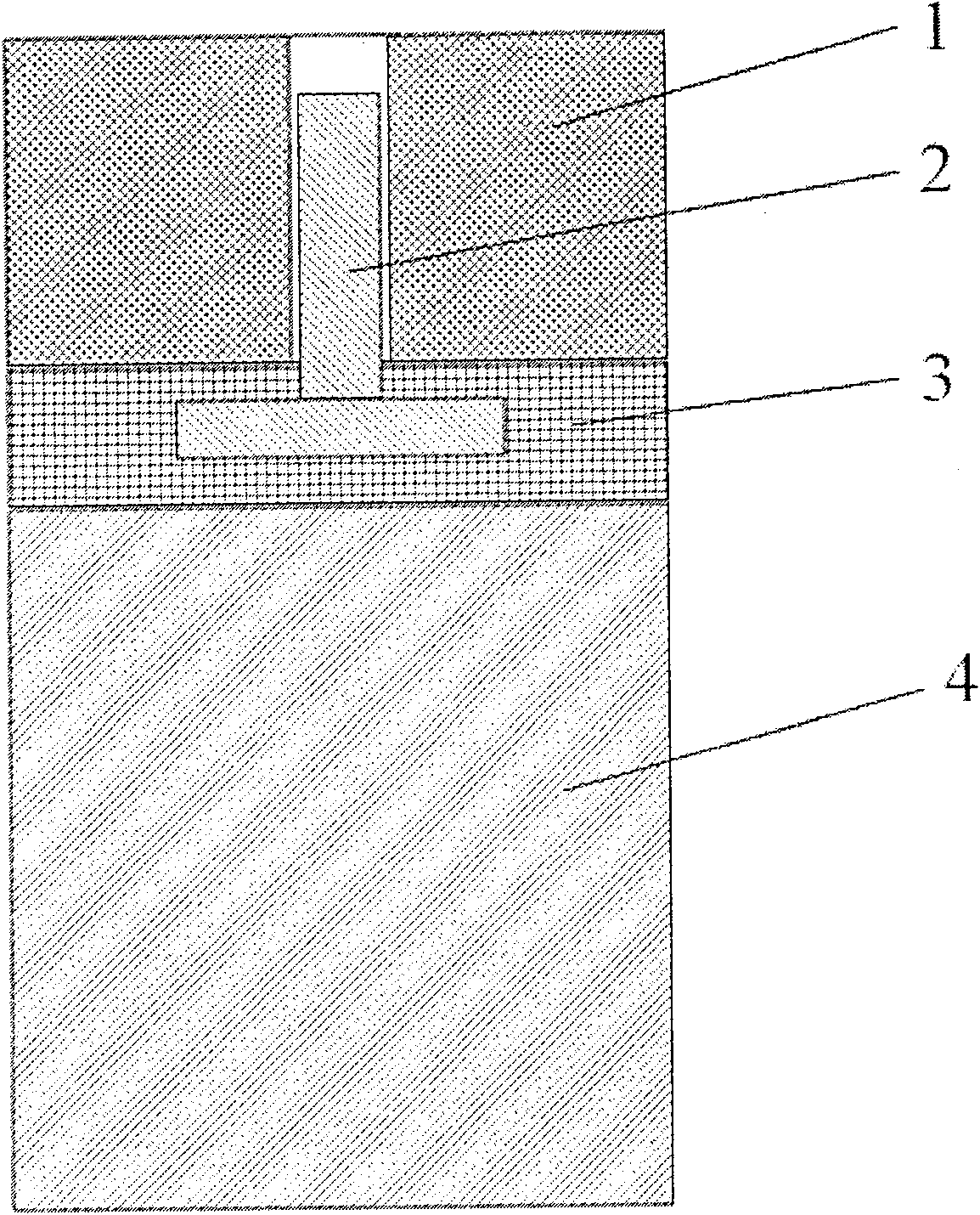

[0024] image 3 A schematic diagram of the connection process of a cylindrical or square inert anode, which mainly includes an indenter 1, a conductive rod 2, a solder 3, and a cylindrical or square inert anode 4. The composition is NiFe 2 O 4 -10NiO / 17Cu inert anode, conductive rod material is Cr18Ni9Ti. The process of pressure diffusion welding is as follows: First, the to-be-connected surface of the inert anode and the outer surface of the conductive connecting rod are electroplated with copper, the plating thickness is about 150μm, and then the composition is 62wt% NiFe 2 O 4 -10NiO / 17Cu+38wt%Cu powder solder is spread on the surface of the anode to be connected, and a powder fixing device is added if necessary to ensure the thickness and shape of the solder layer, and then the conductive rod is buried in the solder powder , And finally put the indenter above the solder powder to complete the assembly work. The above assembly structure is placed in an electric furnace, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com