Method for assembling semiconductor chips, and corresponding semiconductor chip assembly

A semiconductor and chip technology, applied in the field of semiconductor chip devices, can solve problems such as increased cost, and achieve the effects of favorable energy efficiency, high K coefficient, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The same reference numerals in the drawings indicate the same or functionally identical components.

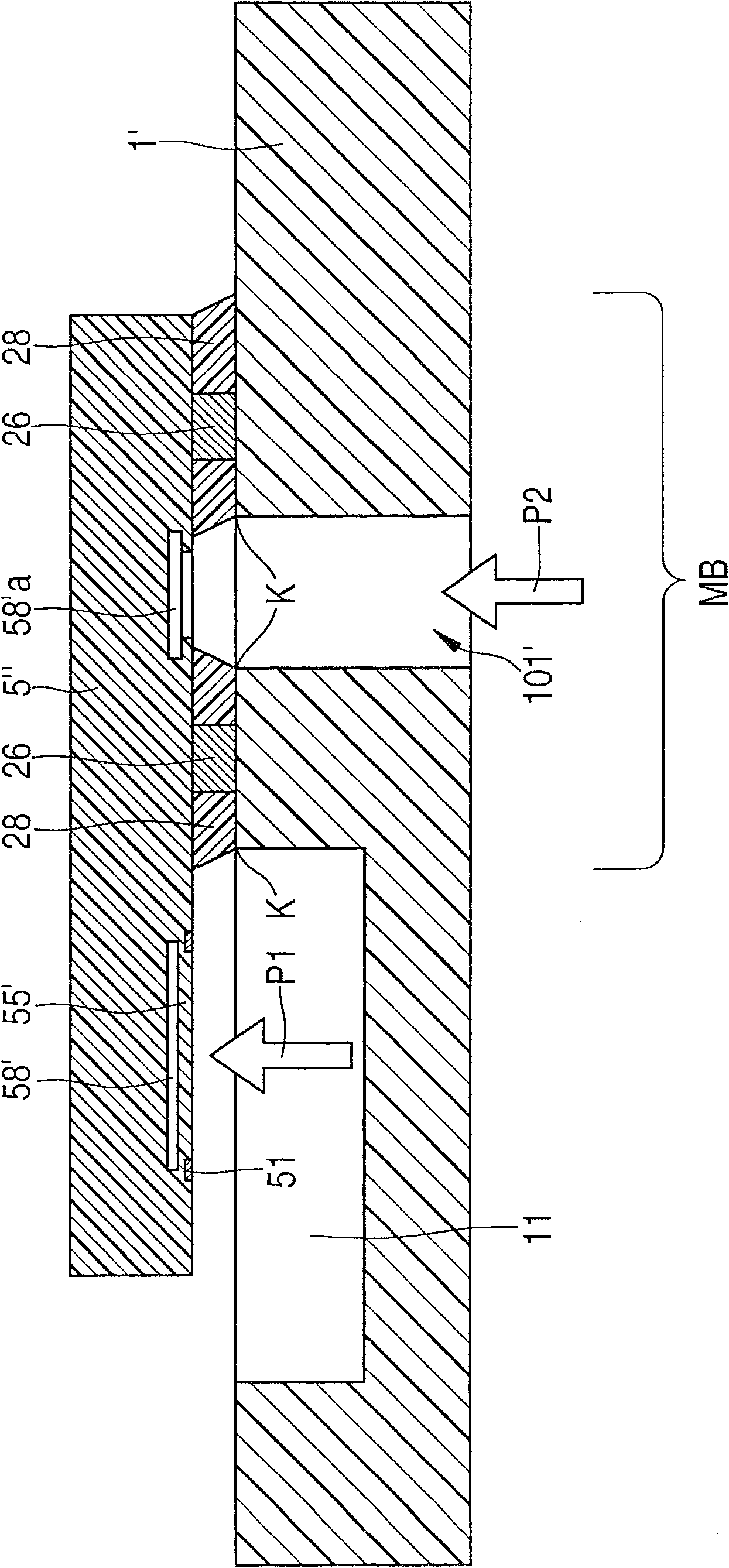

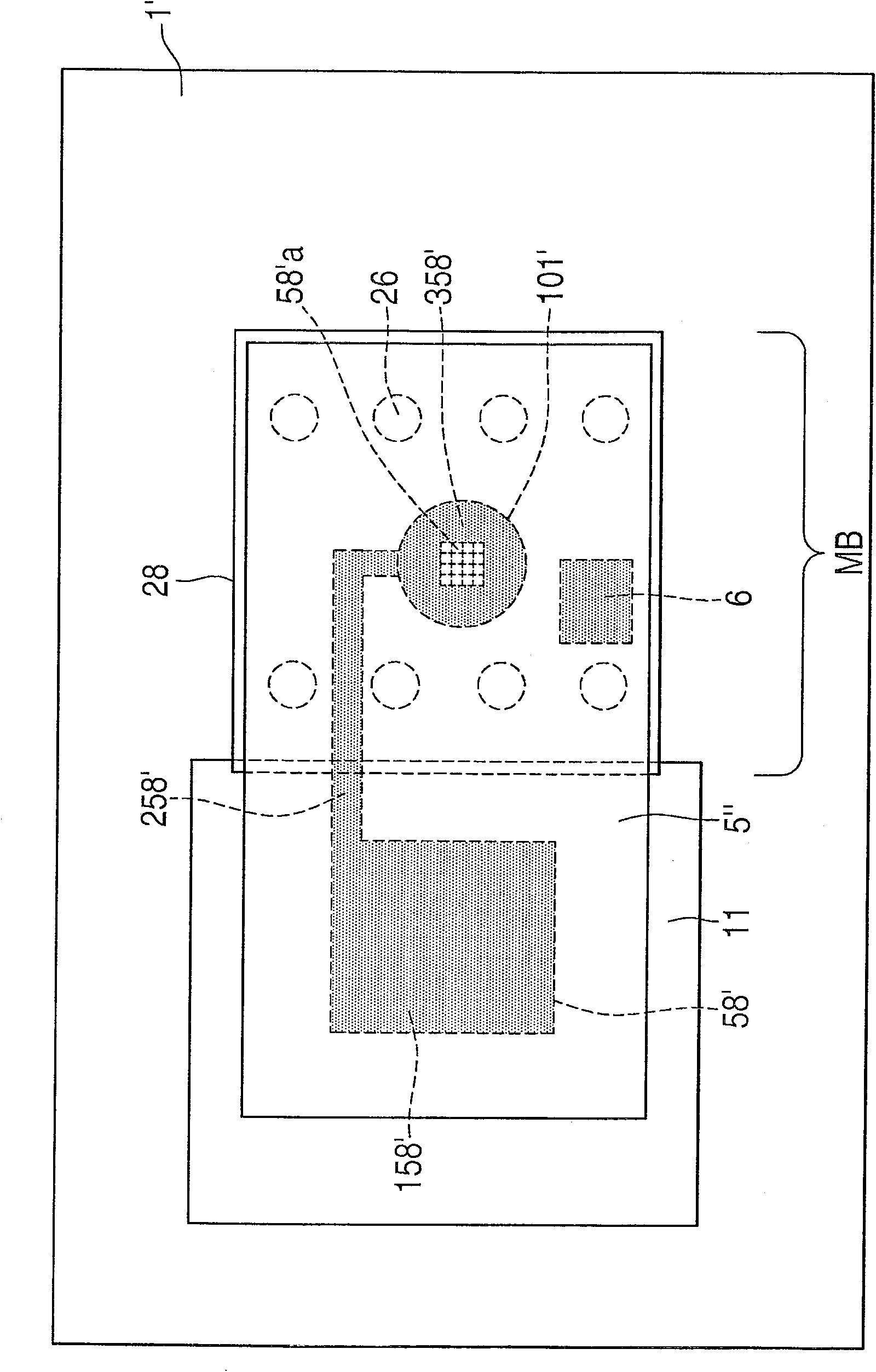

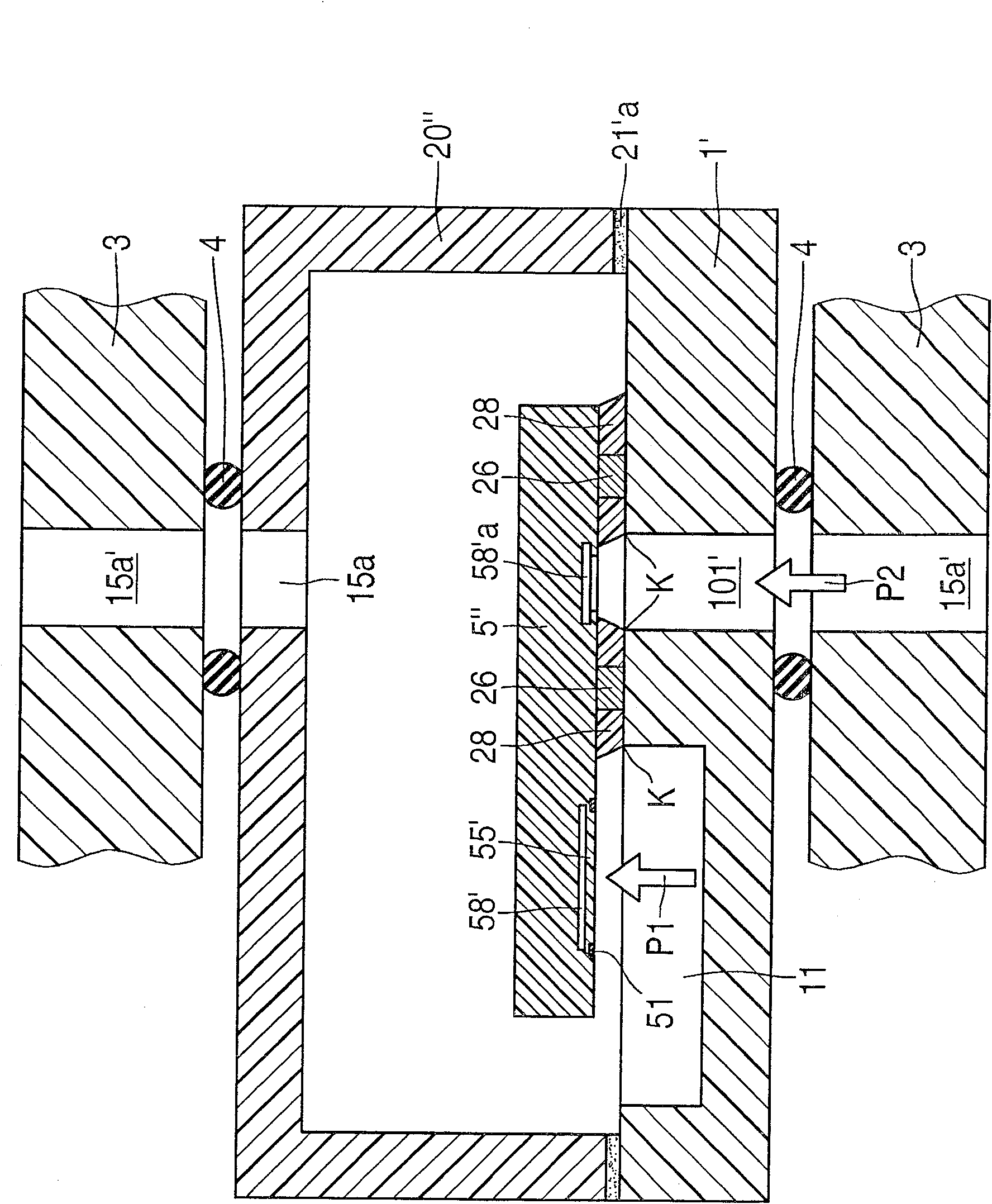

[0053] Figure 1a , b represents a lateral and horizontal cross-section of a first embodiment of the method for mounting semiconductor chips and the corresponding semiconductor device according to the invention.

[0054] In this example the sensor chip 5 ″ is a surface micromechanical sensor chip which is produced, for example, according to the method described in DE 100 32 579 A1 and which has a cavity 58 ′ combined on a membrane region 55 ′.

[0055] For assembly, the bonding pads of the sensor chip 5 ″ are soldered to the (not shown) bonding pads of the substrate 1 ′ in a mounting region MB by means of a solder or adhesive connection, for example by means of a solder bead 26 , here the substrate is a printed circuit board or ceramic and has a recess 11 next to which the sensor chip 5 ″ is mounted suspended in flip-chip technology.

[0056] The assembly area MB also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com