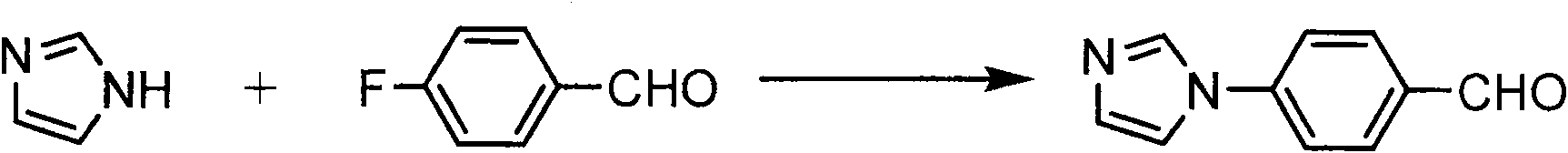

Method of synthesizing p-N-imidazolyl benzaldehyde

A synthesis method and a technology for p-fluorobenzaldehyde, which are applied in directions such as organic chemistry, can solve the problems of increased production time and production cost, complicated and complicated separation methods, shortened synthesis time, etc., so as to achieve shortened production time, simple and feasible method, and reduced production time. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

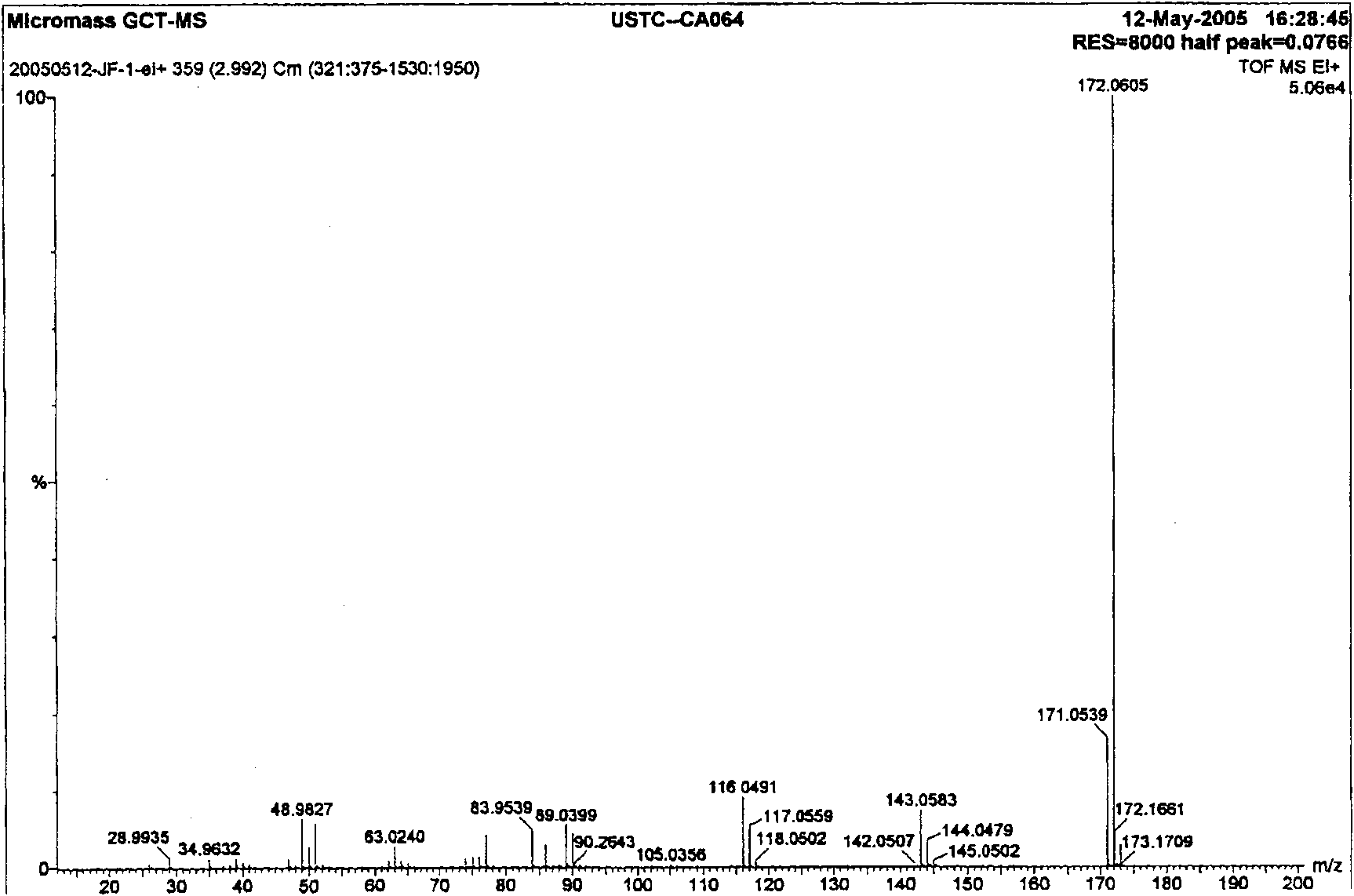

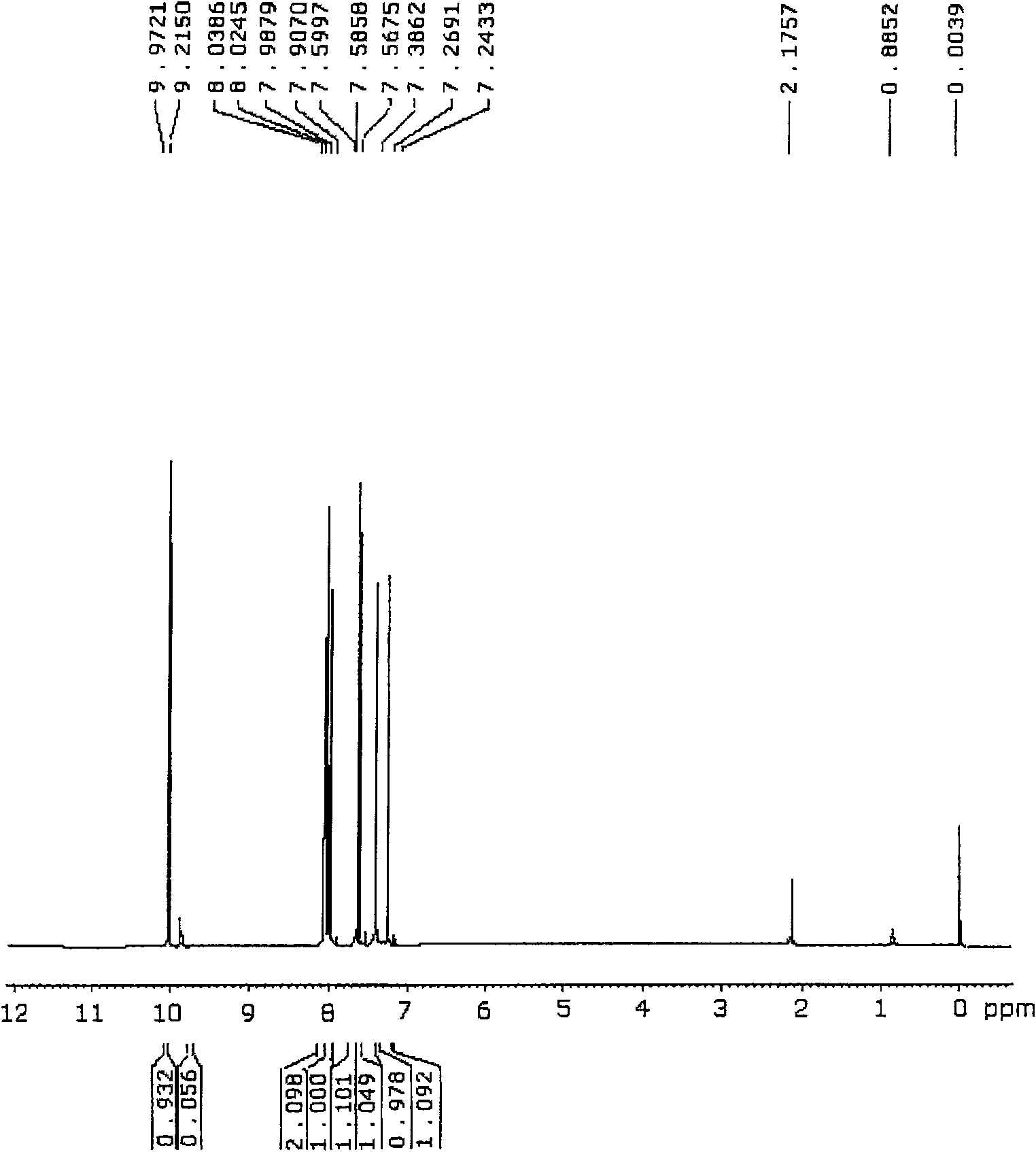

Embodiment 1

[0023] (1) Use DMF as a solvent, add imidazole and a catalyst, gradually heat up to 90°C, after 5min, add p-fluorobenzaldehyde dropwise three times, react at 80°C for 10 hours to obtain a reaction mixture;

[0024] Add 30ml DMF to a 100mL round bottom flask, weigh 3.4g (0.05mol) imidazole, 5.0g K 2 CO 3 Add the powder into the flask, stir, add 3 drops of phase transfer catalyst aliquat336 dropwise, and gradually raise the temperature to 90°C. After 5 minutes, add 5.4mL p-fluorobenzaldehyde dropwise in three times, the solution turns light yellow. After the dropwise addition, adjust the temperature is 80°C. After 10 hours, the heating was stopped.

[0025] (2) The reaction mixture was purified by freeze separation.

[0026] The cooled reaction mixture was poured into 150 mL of ice water, stirred, and a large amount of yellow precipitates appeared. Freeze at 0°C for 30 minutes to obtain more precipitates, filter them with suction, and dry them in vacuum to constant weight. T...

Embodiment 2

[0028] (1) Use DMF as a solvent, add imidazole and a catalyst, gradually heat up to 90°C, after 5min, add p-fluorobenzaldehyde dropwise three times, react at 80°C for 10 hours to obtain a reaction mixture;

[0029] Add 30ml DMF to a 100mL round bottom flask, weigh 3.4g (0.05mol) imidazole, 5.0g K 2 CO 3 Add the powder into the flask, stir, add 3 drops of phase transfer catalyst aliquat336 dropwise, and gradually raise the temperature to 90°C. After 5 minutes, add 5.4mL p-fluorobenzaldehyde dropwise three times, and the solution turns light yellow. After the dropwise addition, the temperature is adjusted to 80°C. After 10 hours, the heating was stopped.

[0030] (2) The reaction mixture was purified by freeze separation.

[0031] The cooled reaction mixture was poured into 160 mL of ice water, stirred, and a large amount of yellow precipitates appeared. Freeze at -5°C for 30 minutes to obtain more precipitates, filter with suction, and vacuum-dry to constant weight. It is l...

Embodiment 3

[0033] (1) Use DMF as a solvent, add imidazole and a catalyst, gradually heat up to 90°C, after 5min, add p-fluorobenzaldehyde dropwise three times, react at 80°C for 10 hours to obtain a reaction mixture;

[0034] Add 30ml DMF to a 100mL round bottom flask, weigh 3.4g (0.05mol) imidazole, 5.0g K 2 CO 3 Add the powder into the flask, stir, add 3 drops of phase transfer catalyst aliquat336 dropwise, and gradually raise the temperature to 90°C. After 5 minutes, add 5.4mL p-fluorobenzaldehyde dropwise three times, and the solution turns light yellow. After the dropwise addition, the temperature is adjusted to 80°C. After 10 hours, the heating was stopped.

[0035] (2) The reaction mixture was purified by freeze separation.

[0036] The cooled reaction mixture was poured into 180 mL of ice water, stirred, and a large amount of yellow precipitates appeared. Freeze at -18°C for 30 minutes to obtain more precipitates, filter with suction, and dry in vacuum to constant weight, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com