Analytical investigating method of perfluor n-pro-pyl vinyl ether

A technology of perfluoro-n-propyl vinyl ether and n-propyl vinyl ether, which is applied in the field of analysis and measurement of perfluoro-n-propyl vinyl ether, can solve the problems of being unsuitable for routine analysis of enterprises and expensive instruments, and achieves The effect of high practical value and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1.1 Instrument

[0019] Agilent 6890 Chromatograph

[0020] 1.2 Chromatographic conditions

[0021] Detector: FID (Flame Ionization Detector)

[0022] Column: DB-17

[0023] Column length: ¢0.25*30m

[0024] Column temperature: 40°C

[0025] Injector: 120°C

[0026] Detector: 300°C

[0027] 1.3 Sample analysis

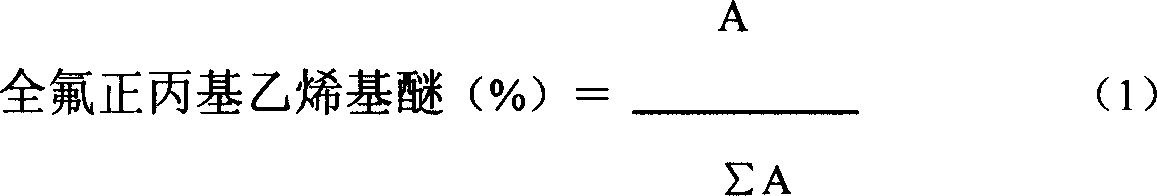

[0028] Since the sample is extremely volatile, be careful to move quickly when injecting the sample. Quickly sample 1uL for chromatographic analysis, and obtain the content of perfluoro-n-propyl vinyl ether according to the following formula.

[0029]

[0030] In the formula: A is the peak area of perfluoro-n-propyl vinyl ether

[0031] ΣA is the total area of each peak.

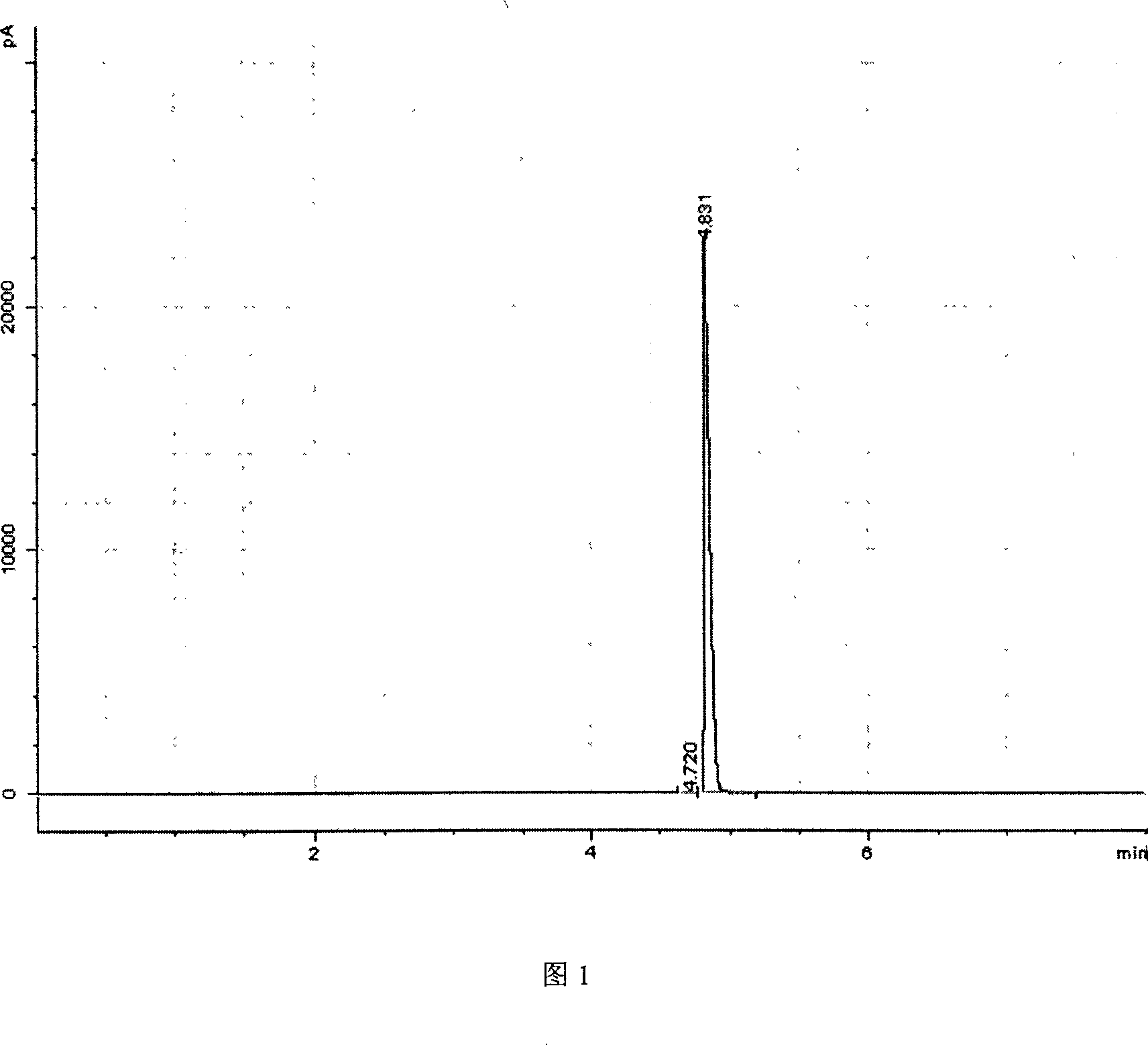

[0032] As shown in Figure 1, the peak area of perfluoro-n-propyl vinyl ether is 658020, and the peak area of hydride is 263, so the content of perfluoro-n-propyl vinyl ether is:

[0033]

[0034] The following is the comparison of the results of nine consecutive determ...

Embodiment 2

[0043] Embodiment 2: the selection of chromatographic conditions

[0044] Install the aged capillary chromatographic columns of DB-1, DB-200, DB-17 with 0.32um liquid film and DB-1, DB-200, DB-17 with 1.0um liquid film respectively in the On the Agilent 6890 chromatographic instrument, the separation degree test was carried out at different temperatures (column temperature), and the results are shown in Table 2 and Table 3. The DB-1, DB-200 and DB-17 are chromatographic column types.

[0045] Table 2 Resolution at different temperatures of a chromatographic column with a liquid film thickness of 1.0um

[0046] NOTE: Resolution indicates how well the components are separated from each other in the column. Adjacent two chromatographic peaks can be completely separated when the resolution is greater than 1.5. Only when the resolution is good can the measurement results have sufficient parallelism and accuracy.

[0047] Table 3 The resolution of the chromatographic column wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com