Composite insulating brick, and process technique

A technology of composite thermal insulation and thermal insulation board, which is applied in the direction of manufacturing tools, building materials, ceramic molding machines, etc., can solve the problems of low bonding strength, unsatisfactory thermal insulation effect, and difficulty in mass production, and achieves control quality, good thermal insulation effect, Excellent water absorption ability

Inactive Publication Date: 2010-12-01

宁波荣山新型材料有限公司

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention solves the problems of unsatisfactory thermal insulation effect, difficulty in large-scale production, and low bonding strength with the wall in the prior art, and provides a brick with high bonding strength (conforming to the "Construction Engineering Facing Brick Bonding Strength") Inspection standard"), the heat-insulation facing brick integrating decoration and heat-preservation function and its production method which are easy to industrialized production, the heat-insulation brick made by the process of the present invention has high strength, is not easy to loose, and has a good heat-preservation effect, which is beneficial to energy saving Environmental protection is of great significance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

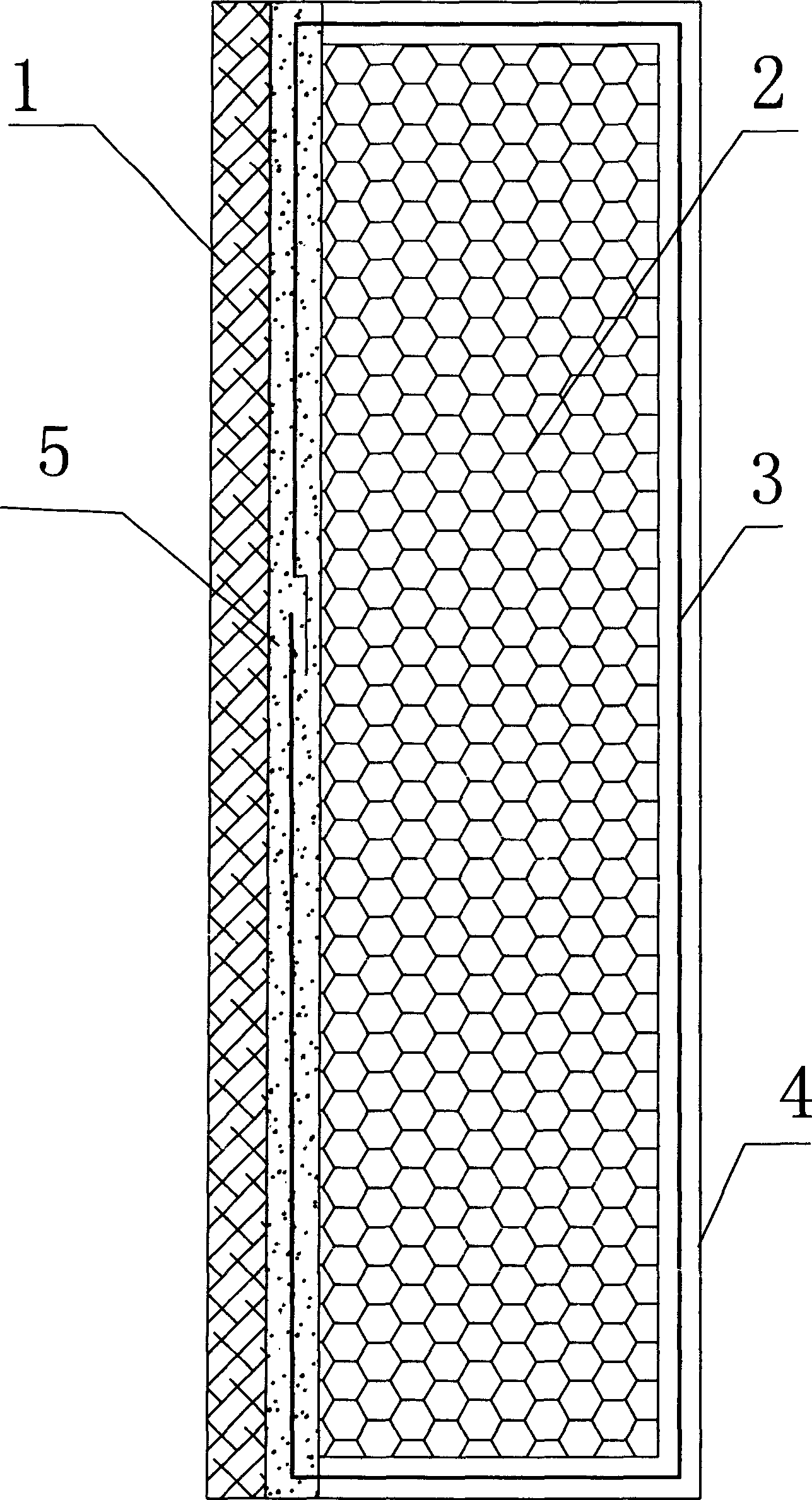

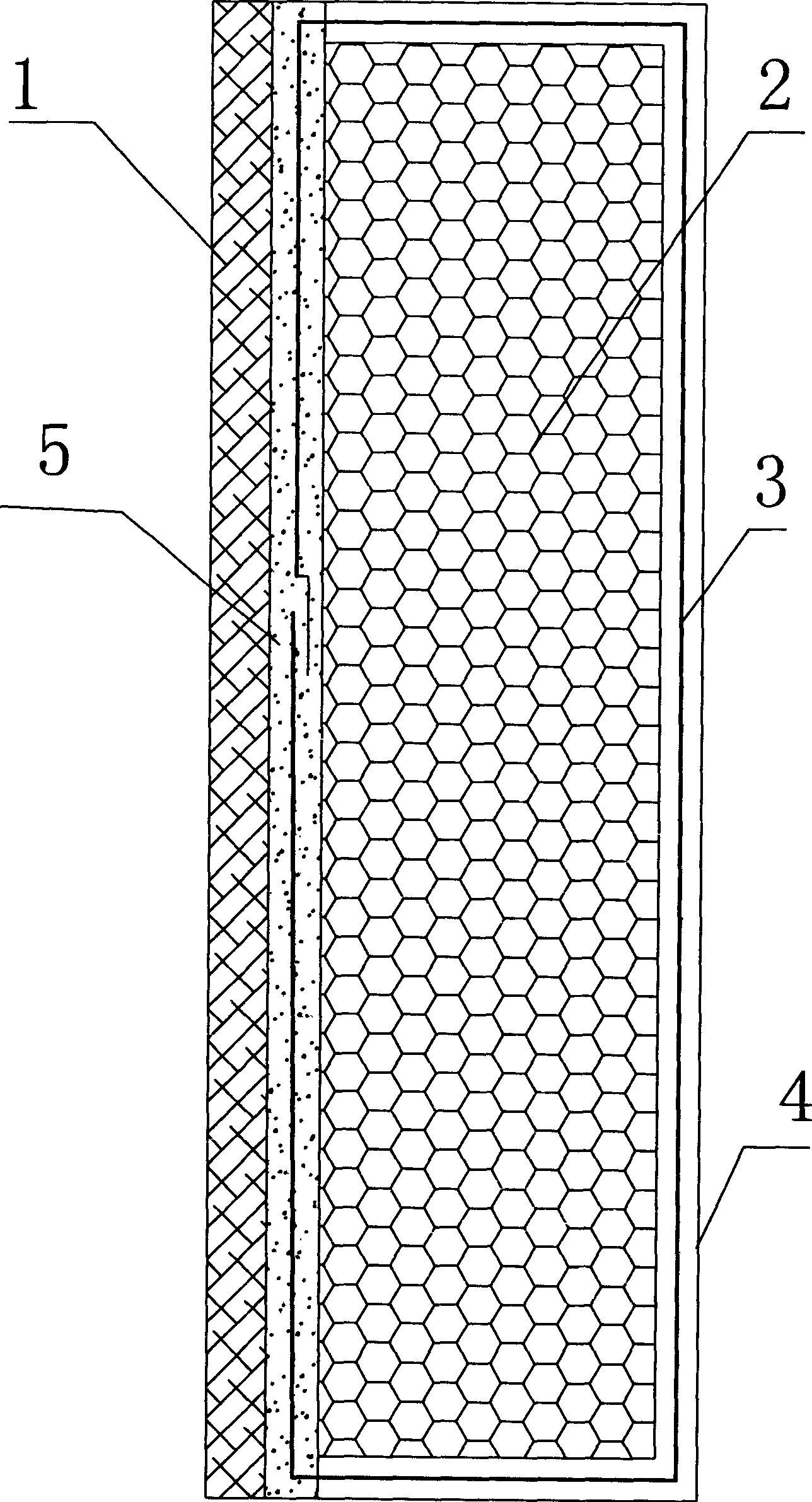

The present invention relates to a composite heat-insulating brick and its production process, belonging to the field of building material. It is characterized by that it includes facing brick, net fabric and heat-insulating plate. The net fabric is sandwiched between facing brick and heat-insulating plate. Said facing brick, net fabric and heat-insulating plate are connected together by means ofadhesive and formed into a whole body. Said composite heat-insulating brick has good strength and heat-insulating effect.

Description

A kind of composite insulation brick and its production process technical field The invention relates to a building brick and a production process thereof, in particular to a composite thermal insulation brick for building energy saving and a production process thereof. Background technique The insulation of building walls is an important part of building energy saving. At present, there are two main methods for building wall insulation. One is self-insulation of the wall, and the other is to attach an insulation layer to the ordinary wall. The second method is the main method currently adopted. There are two methods, one is Paste board-type thermal insulation products, and the second is to smear expanded polystyrene board slurry-type thermal insulation products, such as the polyurethane thermal insulation wall described in CN200420064725.9, according to "Construction Engineering Facing Brick Bond Strength Inspection Standard" (JGJ110-97), The average bonding strength sho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04C1/40B28B19/00

Inventor 王志平王智宇王小山阮华

Owner 宁波荣山新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com