Memory module refrigerating body

A memory module and cooling body technology, which is applied in static memory, cooling/ventilation/heating transformation, instruments, etc., can solve problems such as bending or torsion damage, strong heating of memory units, etc., achieve small flow resistance, ensure cooling, Long-lasting and effective cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

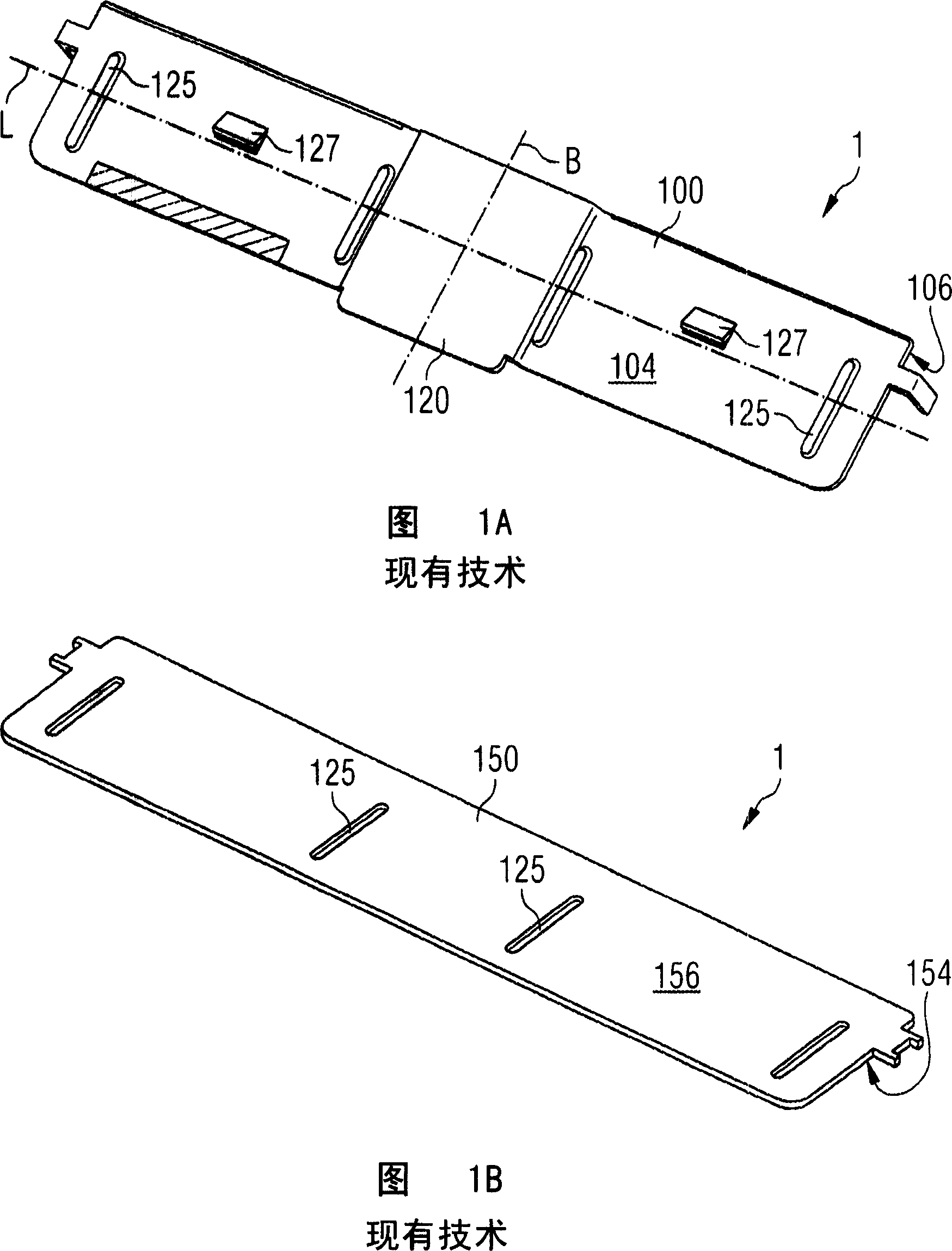

[0039] The invention is explained below on the basis of the prior art shown in FIGS. 1a and 1b.

[0040]A memory module heat sink 1 according to the prior art has a cover plate 100 ( FIG. 1 a ) and a base plate 150 ( FIG. 1 b ). In the center, the cover plate 100 has a cap-shaped groove 120 which projects over the entire width B of the cover plate 100 . That is to say, each section through the entire cover plate 100 in the longitudinal direction L shows a U-shaped section or region with short legs. The hat groove 120 is substantially rectangular, with two mutually parallel sides extending in the width direction B on the cover plate 100 . These two sides are likewise parallel to the longitudinal ends of the cover plate 100 . The side of the cap-shaped groove 120 perpendicular thereto ends by the outer edge of the cover plate 100 , while the side opposite thereto protrudes slightly beyond the side edge of the cover plate 100 .

[0041] Furthermore, the cover plate 100 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com