Lighting apparatus, exposure apparatus and micro device manufacturing method

A lighting device and exposure device technology, which is applied in the direction of photolithographic process exposure device, optical element, semiconductor/solid-state device manufacturing, etc., can solve the mutual interference between the concentrator optical system 211 and the wafer 214, and increase the concentrator optical system Focal length, improving EUV light reflectivity and other issues, to achieve the effect of preventing light loss, preventing reduction in resolution or contrast, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

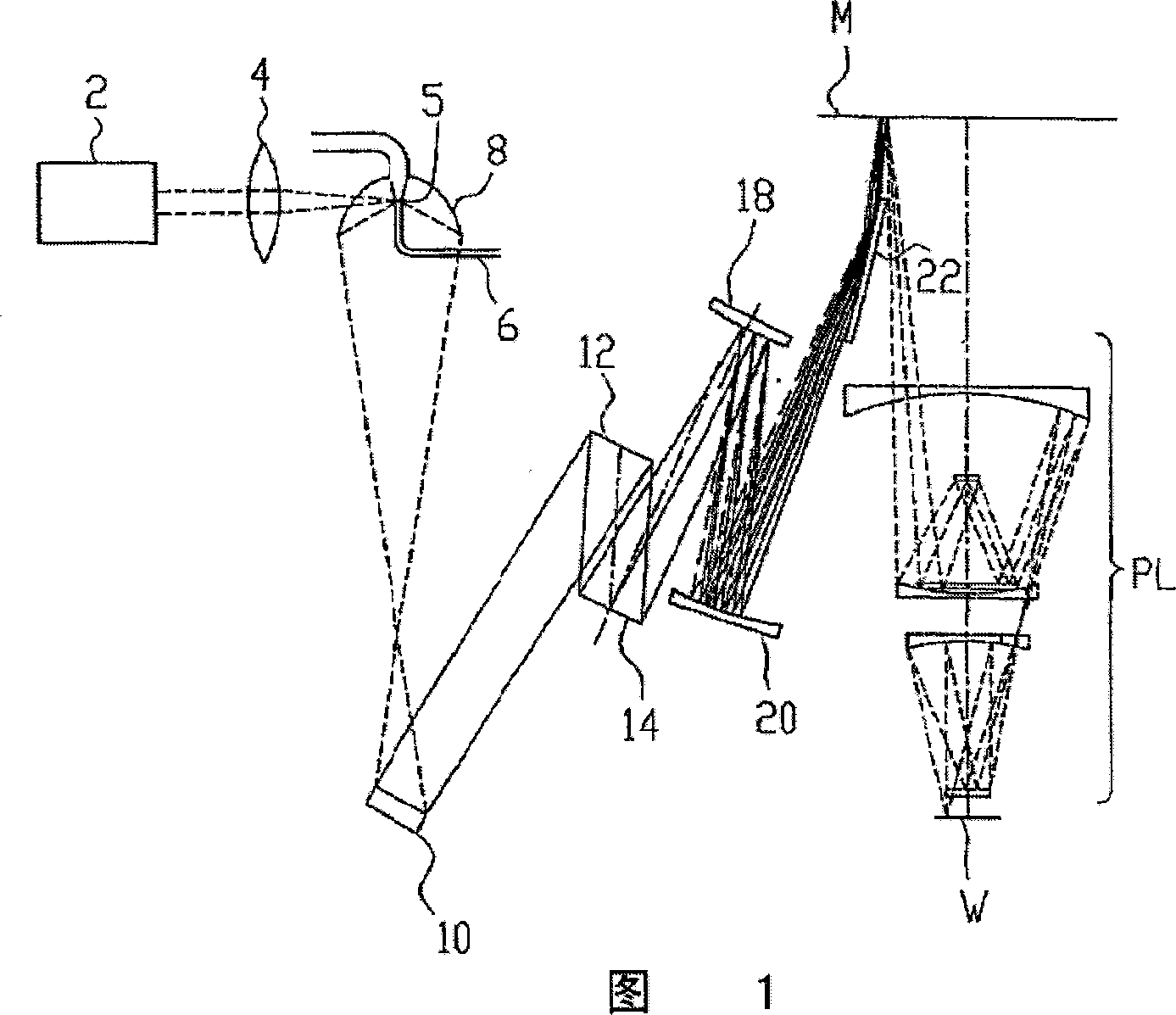

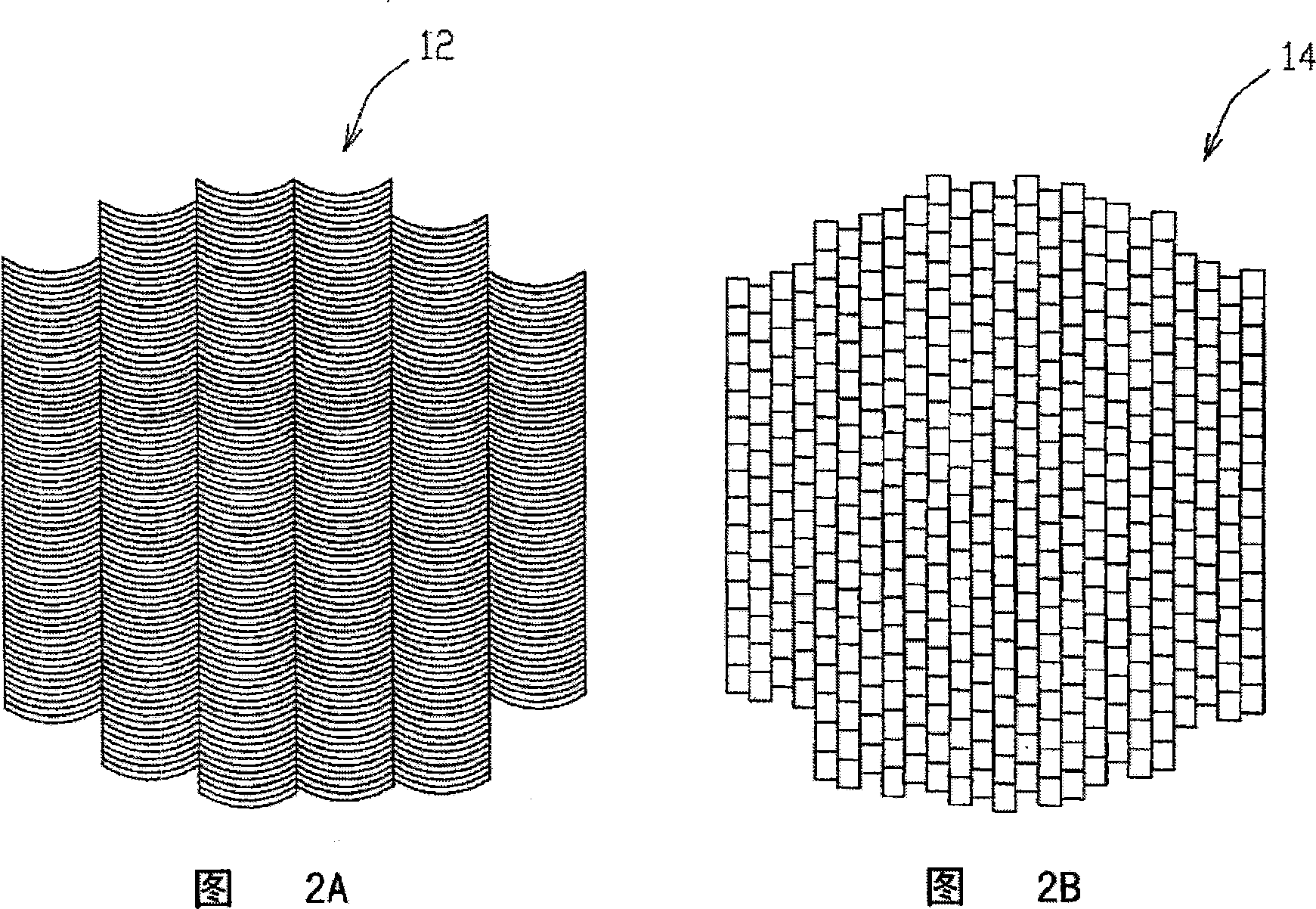

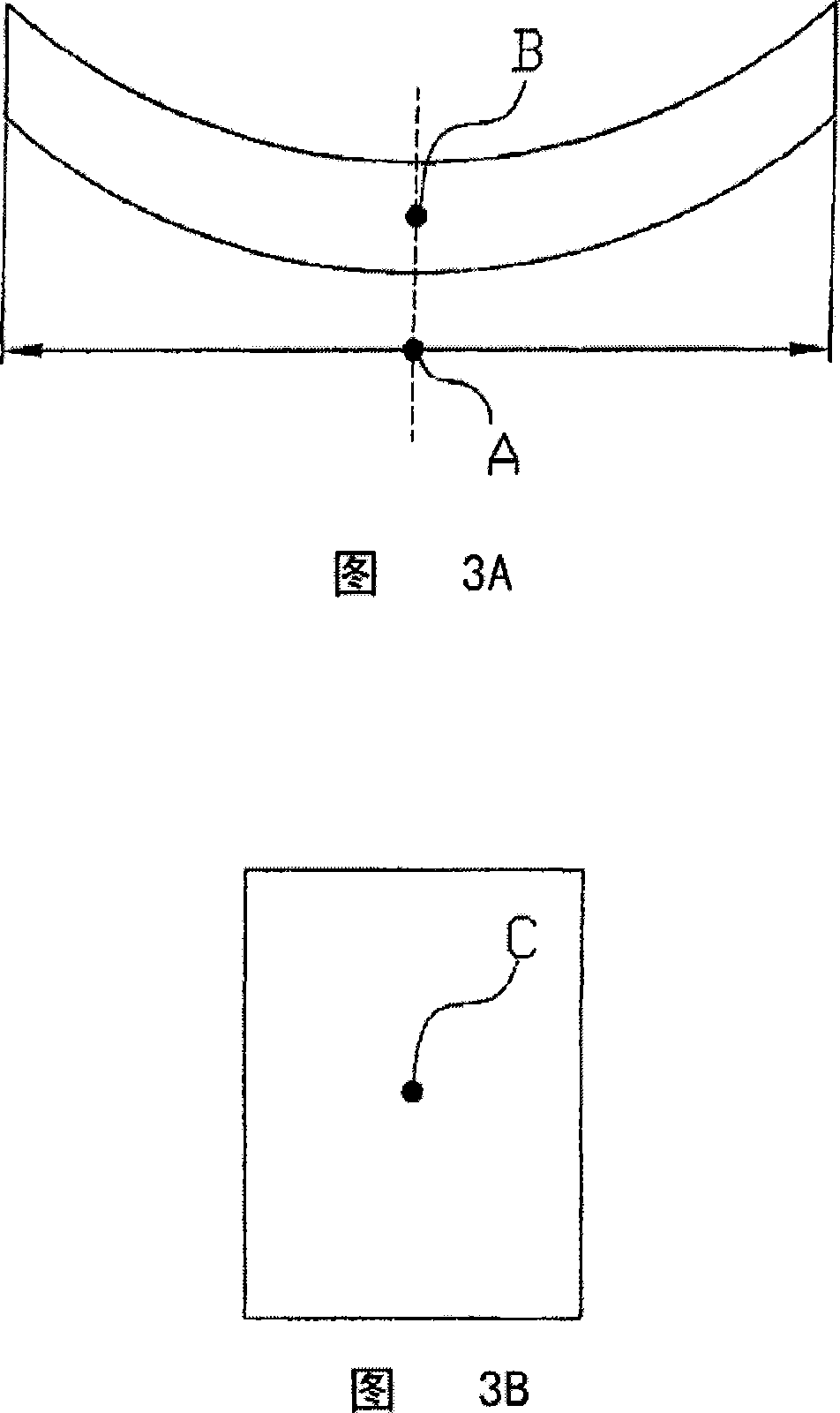

[0067] FIG. 8 shows a schematic configuration of the exit-side fly mirror surface and the condenser optical system constituting the illumination device of this embodiment, and a position diagram of the irradiated surface IMG. Furthermore, the mirror structure of the exit side fly mirror surface and the condenser optical system in this embodiment is the same as the mirror structure of the exit side fly mirror surface 14 and the condenser mirror surfaces 18, 20 of the above-mentioned embodiment shown in FIG. Similarly, when describing the exit-side fly mirror surface and the condenser optical system of the embodiment, the symbols used in the description of the exit-side fly mirror surface 14 and the condenser mirror surfaces 18 and 20 of the above-mentioned embodiment are used.

[0068]According to the format of the optical design software Code V (ORA Corporation), the data of the output-side fly mirror surface 14 and the condenser mirror surfaces 18 and 20 constituting the illum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com