Pressure filtration technology and band type filter press for realizing said process

A belt-type filter press, filter press dehydration technology, applied in the direction of mobile filter element filter, filtration separation, separation method, etc., can solve the problems of complex structure, high cost, poor dehydration effect, etc., and achieve small size and low cost , the effect of uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

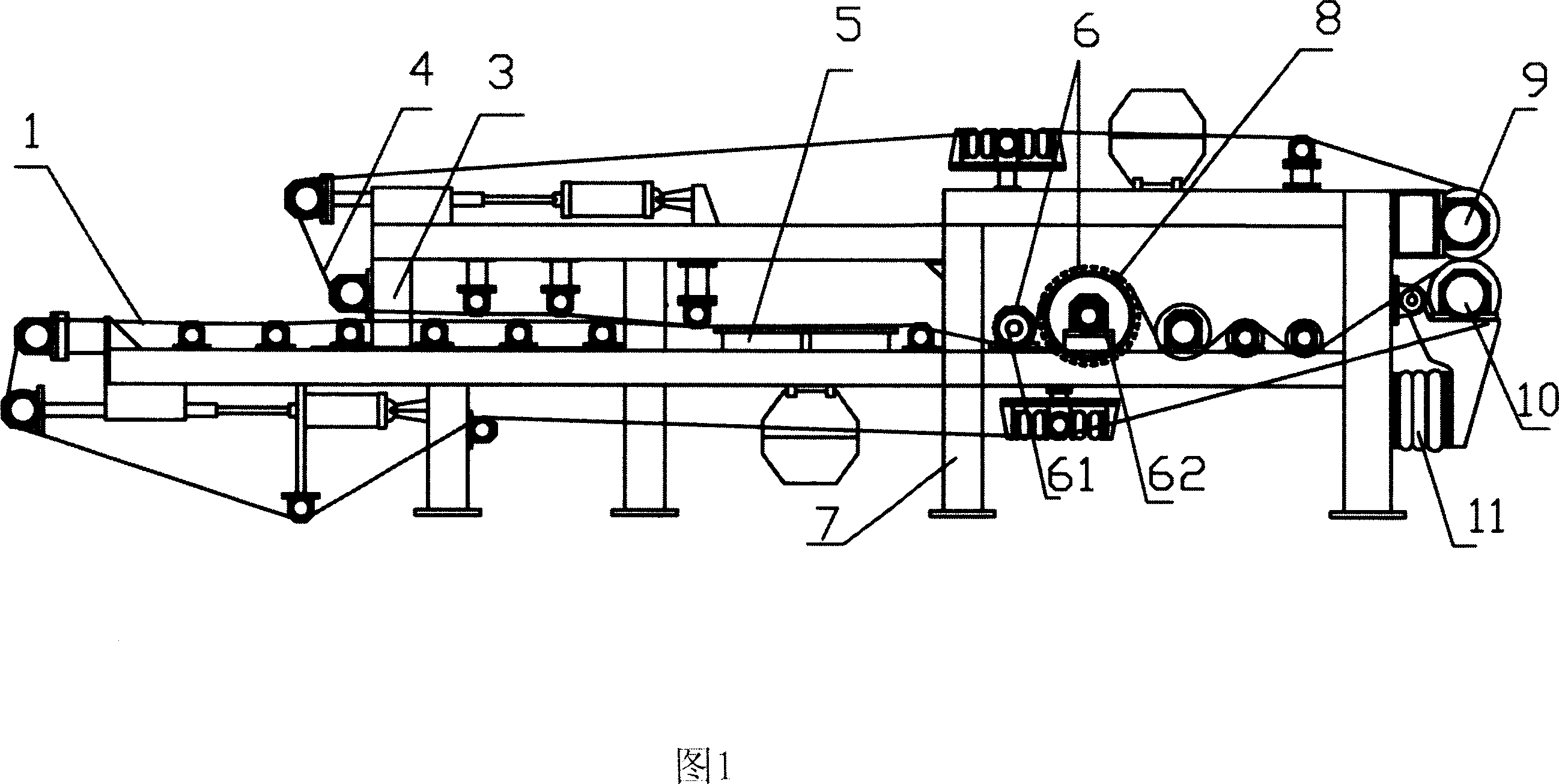

[0050] Referring to Fig. 1, the steps of the filter press dehydration process of the present invention are as follows:

[0051] 1) Spray slurry: spray the paste slurry onto the lower mesh belt 1 through the slurry release box.

[0052] 2) Gravity dehydration: During the power pulling operation, the lower mesh belt 1 is guided to the horizontal gravity dehydration roller 2, and when running through the gravity dehydration roller 2, free dehydration is carried out by gravity, and part of the water can be extracted. The gravity dewatering roller 2 is one, two or more rollers arranged horizontally.

[0053] 3) Forming the filter mesh belt 3: covering the slurry surface with the mesh belt 4, so that the slurry is clamped between the upper and lower mesh belts 1 to form the slurry filter mesh belt 3.

[0054] 4) Adsorption dehydration: make the filter belt 3 run through the vacuum box 5 for vacuum adsorption dehydration, and part of the water can be removed. Vacuum box 5 is advisa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com