Method for mixed bacterial strain to degrade and ferment cellulose for producing hydrogen

A technology for degrading cellulose and cellulose, applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of low utilization rate of cellulose, low hydrogen production, and slow hydrogen production rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

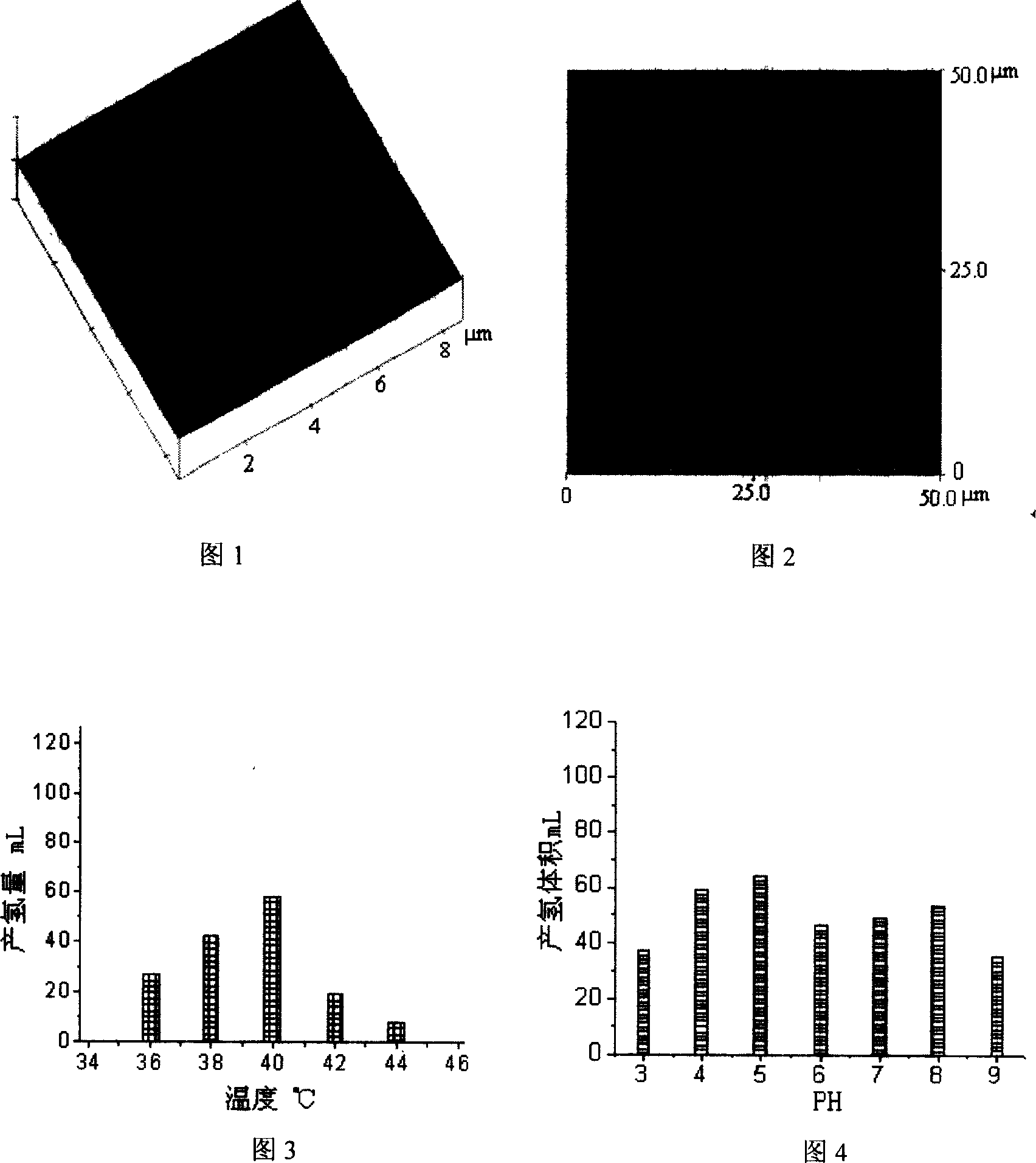

[0006] Specific embodiment 1: The method for producing hydrogen by fermentation of strains compounded to degrade cellulose in this embodiment is carried out according to the following steps: (1) Degrading cellulose by degrading hydrogen-producing bacteria X 9 and efficient hydrogen producing bacteria B 49 Inoculate in the fermentation broth with cellulose as the fermentation substrate; (2) carry out anaerobic fermentation in an environment with a temperature of 35-42°C, a pH value of 3.0-9.0, and high-purity nitrogen as a carrier gas, and ferment for 4-4 8h, a large amount of hydrogen can be obtained.

[0007] Cellulose-degrading hydrogen-producing strain X in this embodiment 9 It is obtained by separating and purifying from the activated sludge of "Organic Wastewater Fermentation Biological Hydrogen Production Equipment" with the patent number 92114474.1, the application date is December 12, 1992, and the authorized announcement number is CN1031392C. First, take the activat...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step (1), the cellulose-degrading hydrogen-producing bacteria X 9 The concentration of the pure culture solution is 571.4g / L, and the high-efficiency hydrogen-producing bacteria B 49 The concentration of the pure culture solution is 577.4g / L, and the cellulose-degrading hydrogen-producing bacteria X 9 and efficient hydrogen producing bacteria B 49 The amount of inoculum used was to inoculate 8-12 mL of pure culture liquid per liter of fermentation liquid. Other steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment two is: cellulose-degrading hydrogen-producing bacteria X 9 and efficient hydrogen producing bacteria B 49 The amount of inoculum was 10 mL of pure culture liquid per liter of fermentation liquid. Other steps are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com