A novel optical fiber grating temperature compensation encapsulation method

A fiber grating and temperature compensation technology, applied in optical fiber transmission, electromagnetic wave transmission systems, electrical components, etc., can solve problems such as temperature coefficient of 1pm/℃, complex packaging structure, increased polarization mode dispersion, etc., and achieve long-term wavelength stability , good long-term temperature characteristics, good effect of temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

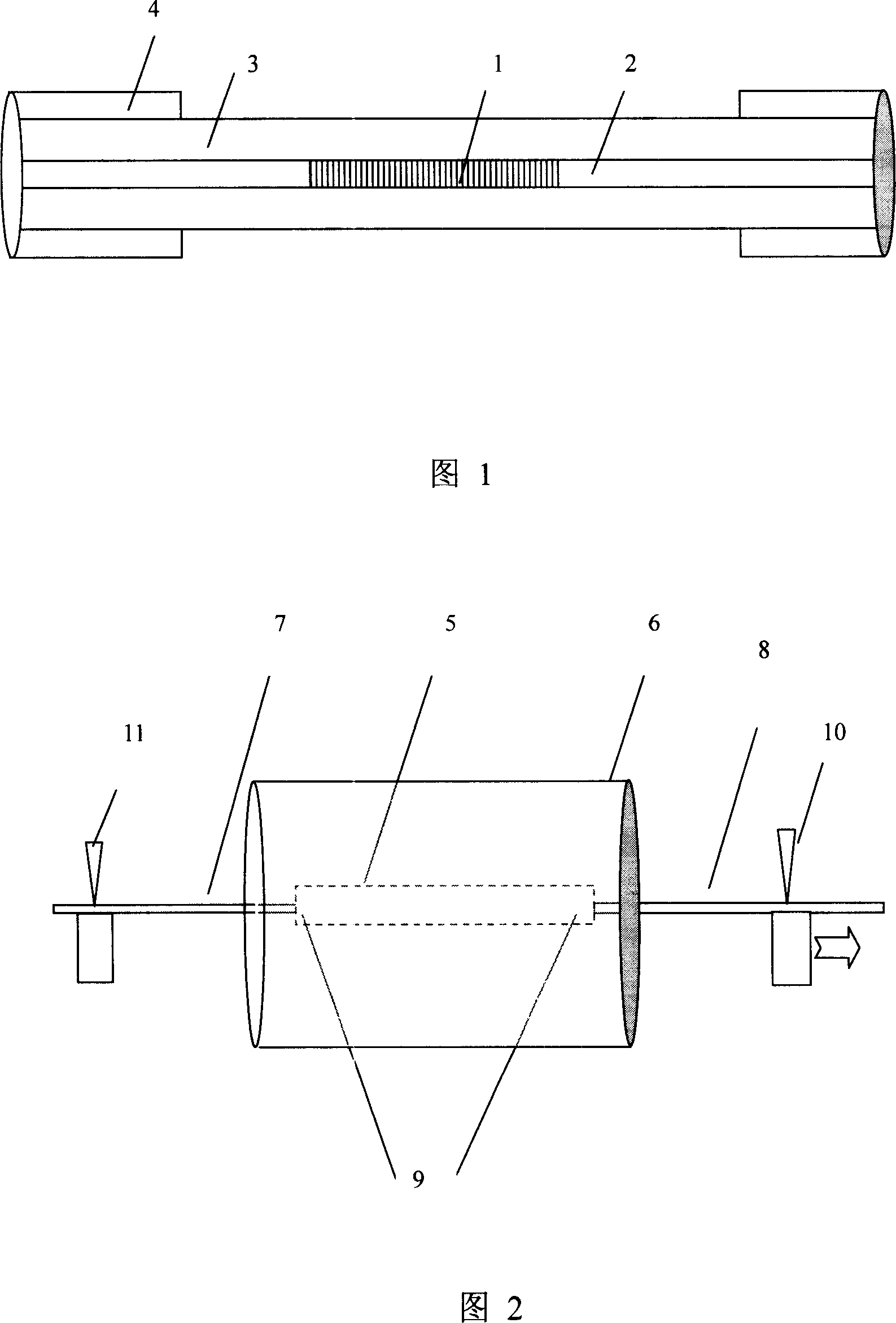

[0018] First of all, in order to make the fiber grating have stable performance, it must be annealed at high temperature for a long time. The structure of the fiber grating written on the photosensitive optical fiber is shown in Figure 1, and the coating layer of the writing grating part must be removed. After the written fiber grating is annealed, the bare optical fiber part where the fiber grating is written should be protected by coating.

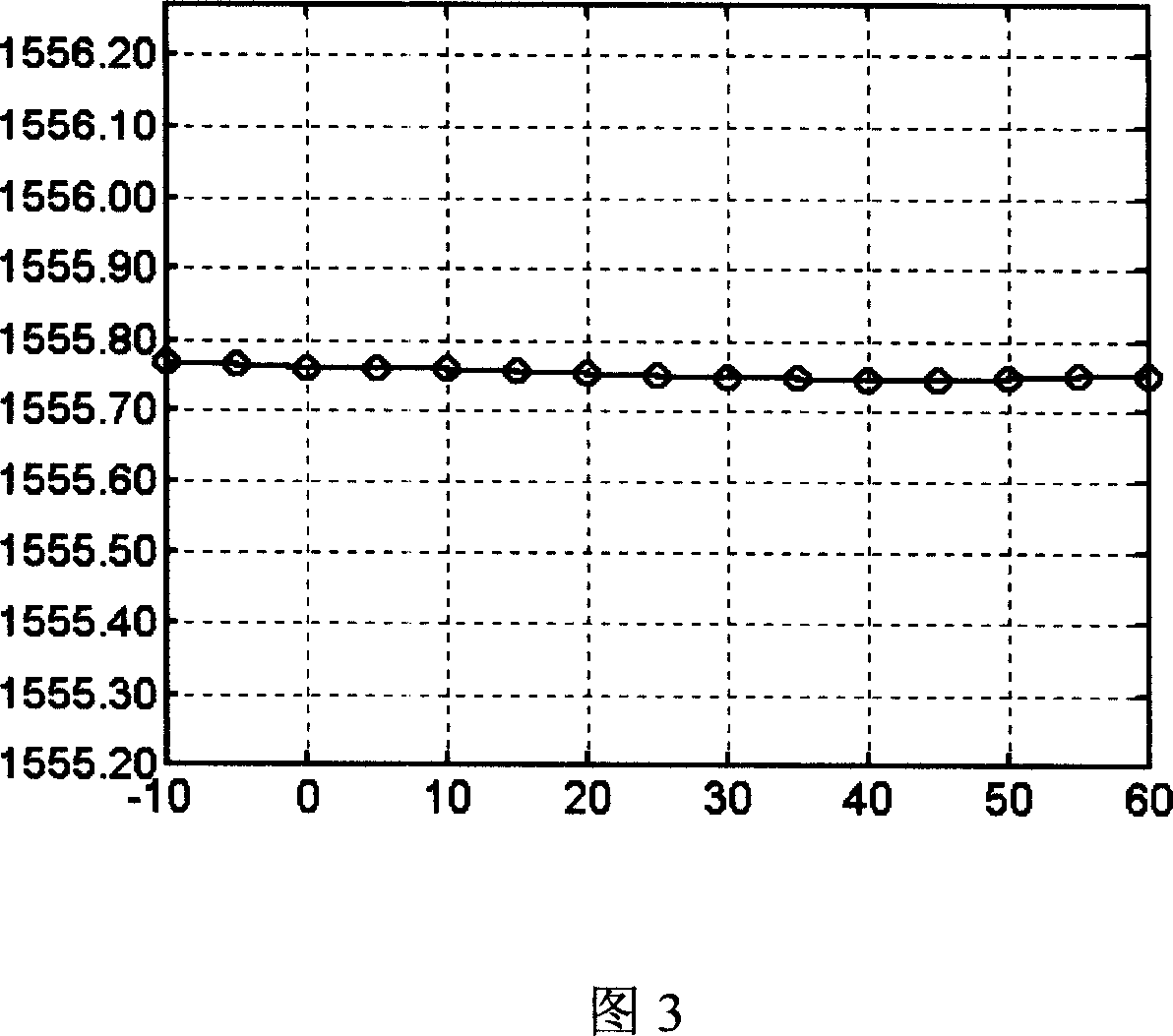

[0019] The second is to make an encapsulating tube with a negative coefficient of thermal expansion. The negative thermal expansion coefficient of the packaging tube is closely related to the production temperature. In order to make the packaged tube just completely compensate for the wavelength drift of the fiber grating, in the process of manufacturing the packaging tube, the high-temperature heat trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com