Automatic controlling method and system of detecting discharge slag from ladle

A slag mixing and vibration signal technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of cumbersome installation process, high maintenance cost, short service life, etc. And the effect of stability guarantee and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

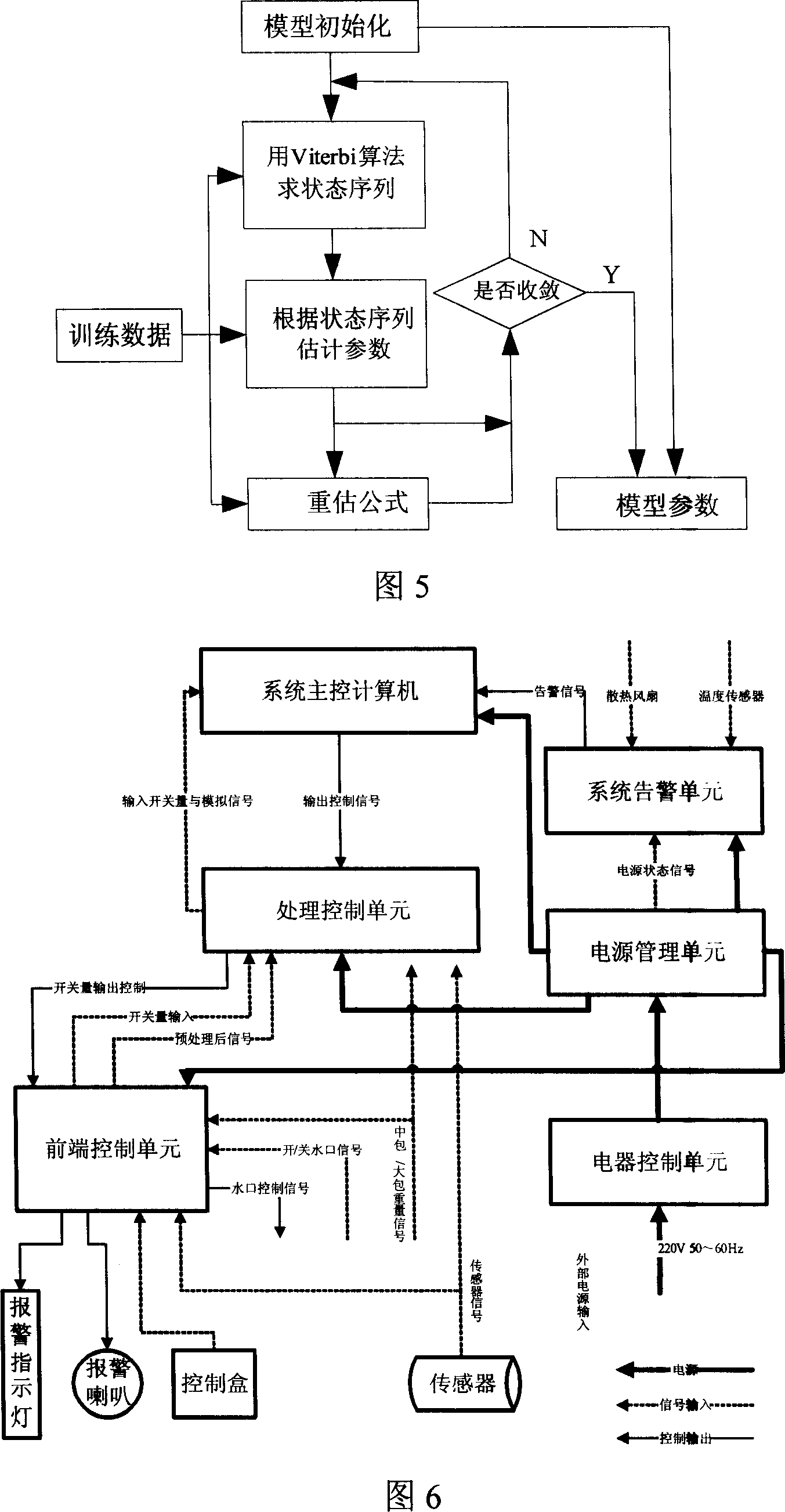

[0038] In conjunction with the accompanying drawings, the present invention will be described in detail below.

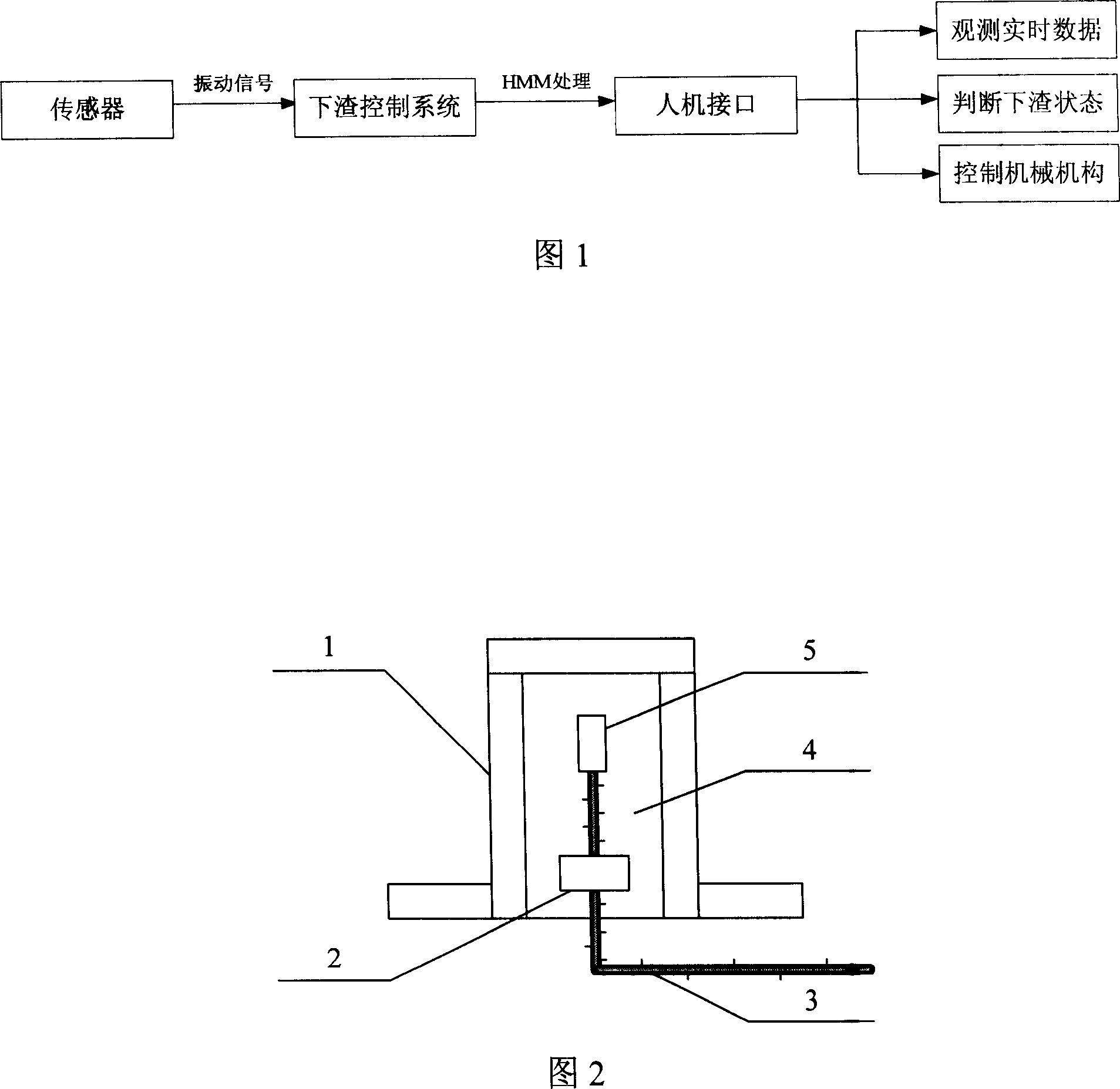

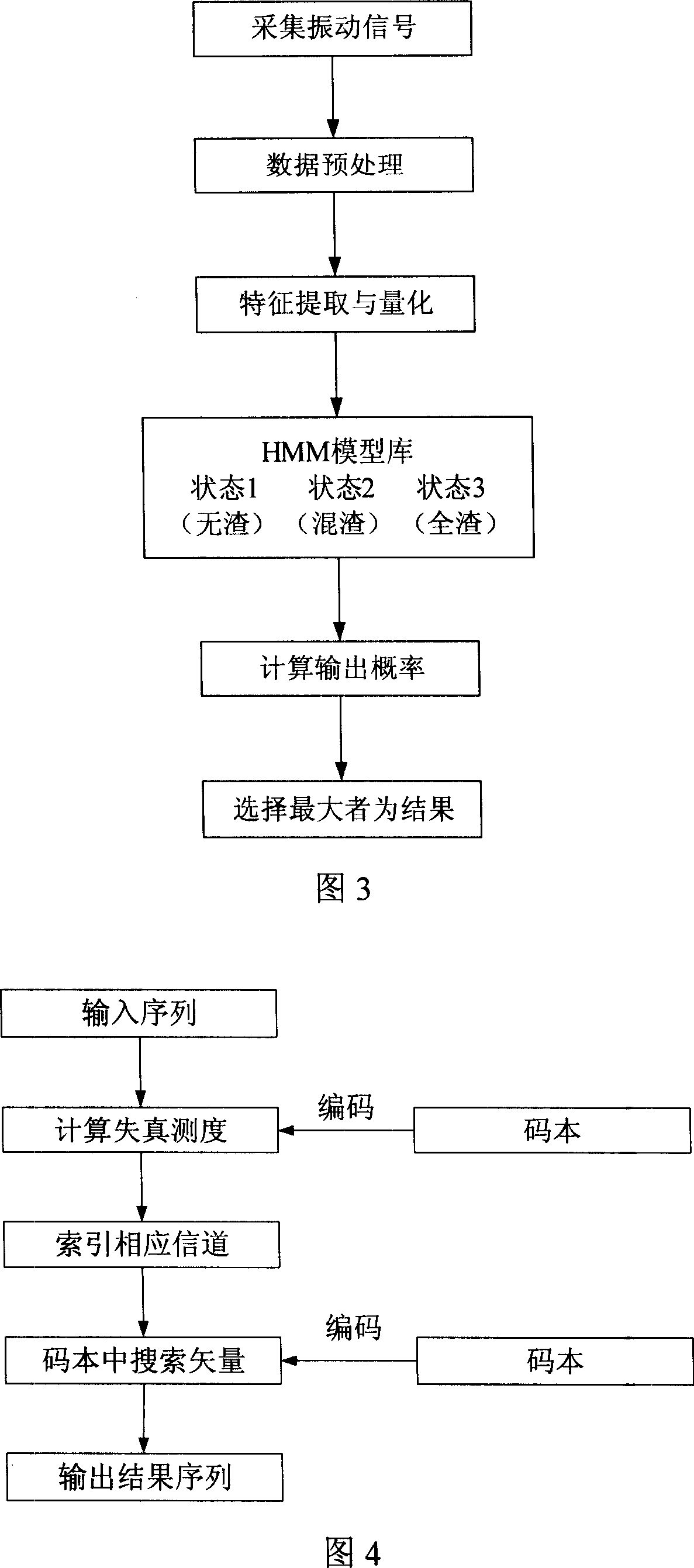

[0039] An automatic control method for ladle slag detection uses a hidden Markov model-based data recognition method (HMM) to process molten steel vibration signals.

[0040] 1. The basis for the automatic control method of ladle slag detection is:

[0041] 1. At the end of molten steel pouring in continuous casting production, the molten steel entrains part of the steel slag and swirls down. At this time, the impact on the shroud shows greater randomness and certainty in terms of impact strength and impact direction. Due to the non-stationarity of the slag, it is difficult to recognize the characteristics of the slag by using traditional data processing methods such as Fourier transform.

[0042] 2. HMM is a signal processing tool with strong time series modeling and pattern recognition capabilities, and is suitable for processing dynamic signals that are non-stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com