Method of manufacturing micro and sub-micron iron powder

A sub-micron and micron-level technology, which is applied in the preparation of sub-micron-level iron powder and micron-level field, can solve the problems of difficult iron powder and high energy consumption, and achieve high reduction rate of iron powder, low energy consumption and easy preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

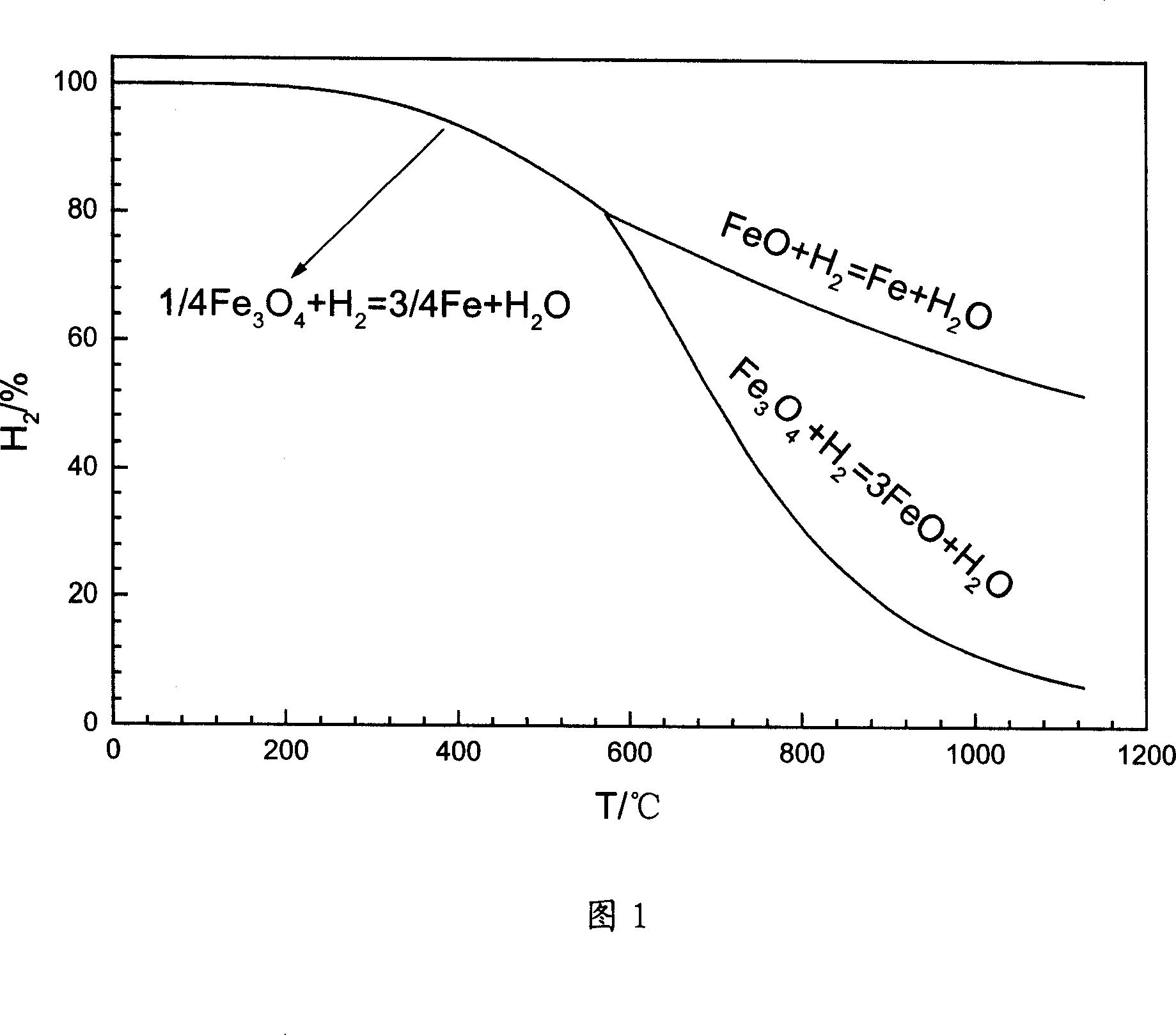

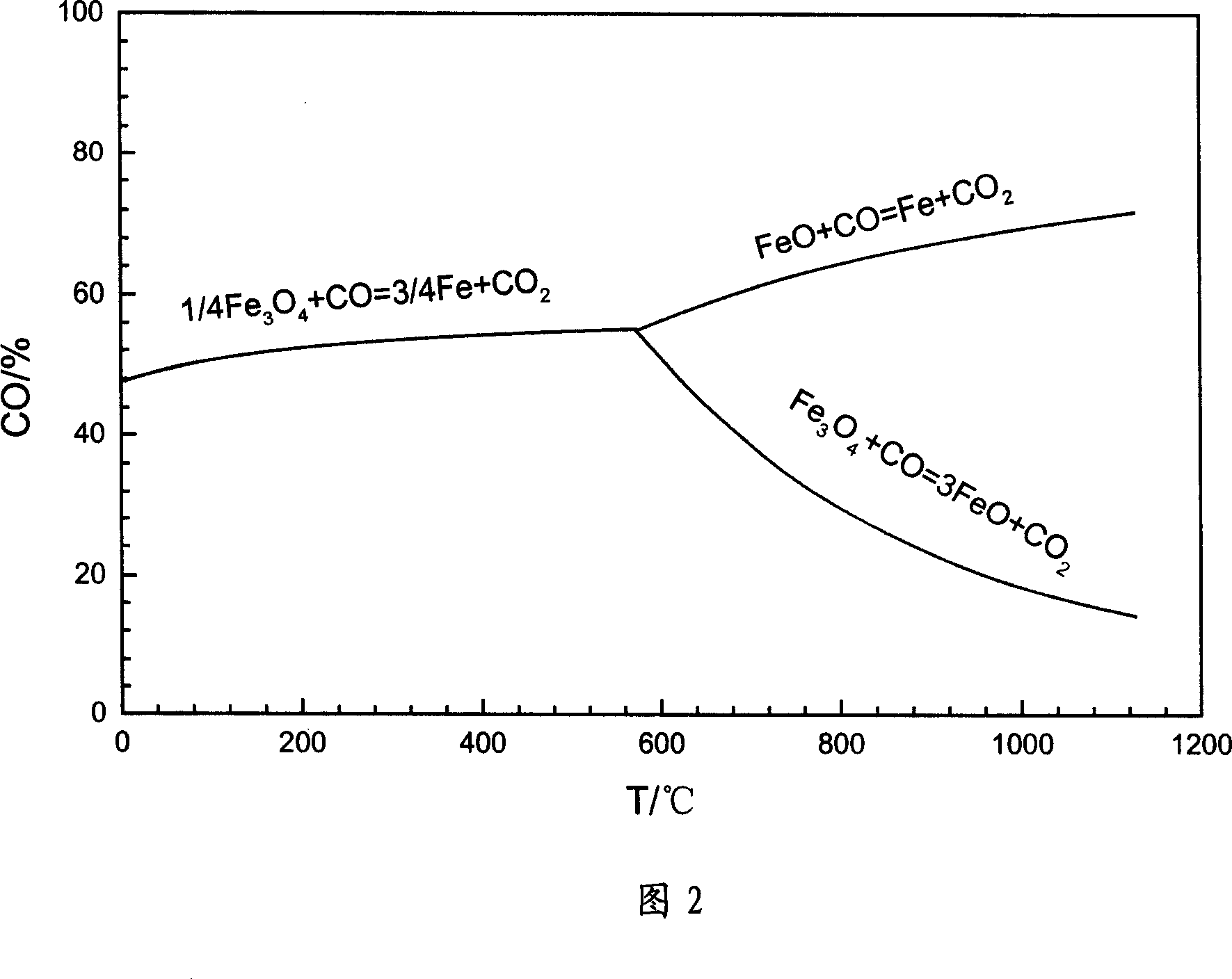

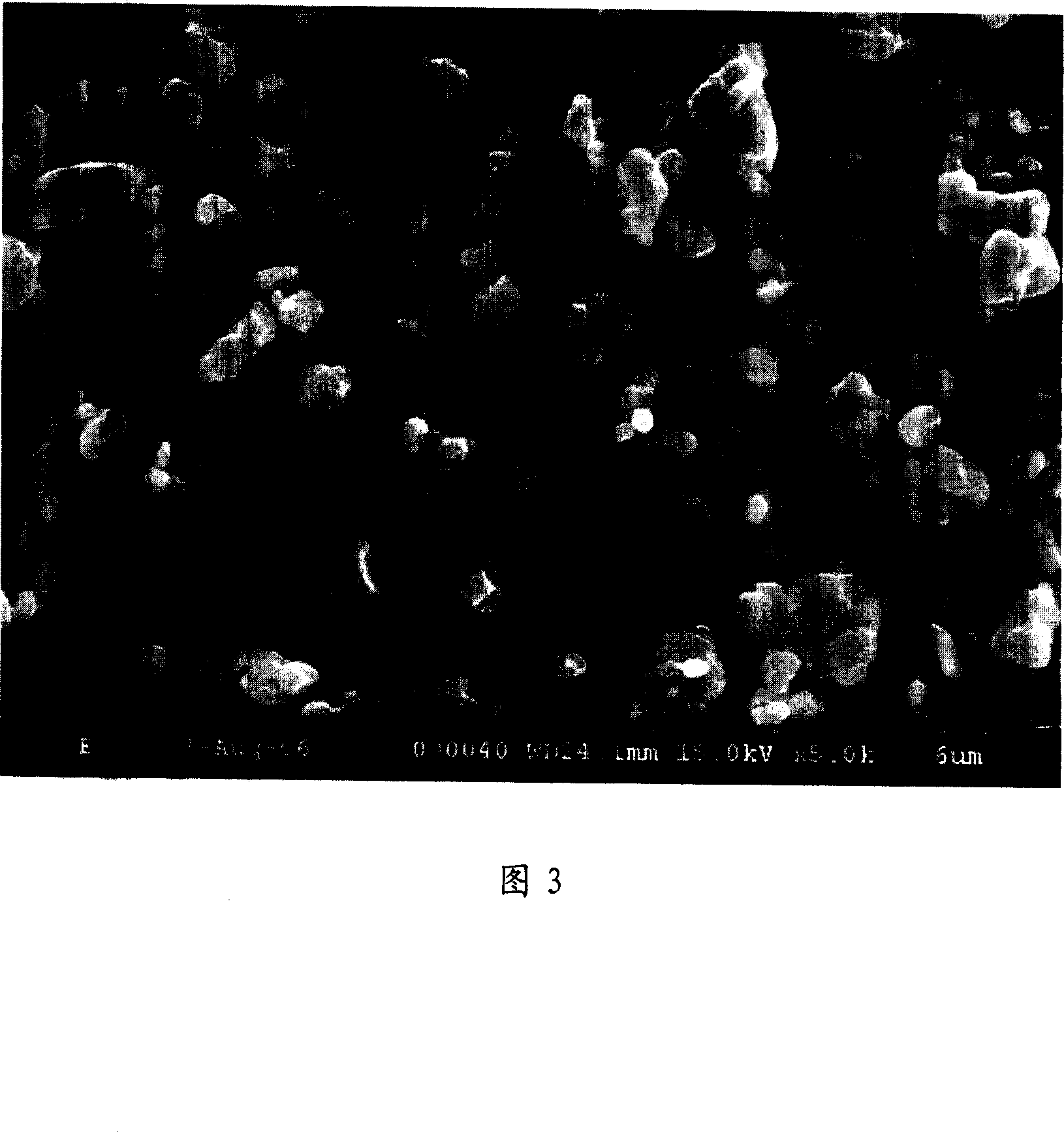

[0034] The implementation of the method of the present invention is to put the analytically pure iron oxide powder in a stirring ball mill with heating function, and feed nitrogen or argon to drive out the air in the ball mill. Start the agitating ball mill to grind the iron oxide powder to below 10 microns, and raise the temperature inside the ball mill to 200-400°C. Switch nitrogen or argon with reducing gas to start reduction, and remove H from the tail gas leaving the ball mill 2 O / CO 2 Finally, after being pressurized by a gas booster, it can be reused. During the experiment, hydrogen, CO, CO 2, Nitrogen, Argon, and Oxygen are commercially produced 99.99% pure gases, and water vapor is obtained through a steam generator. The gas composition is adjusted through a multi-channel gas control system, and an online gas analyzer is used to dynamically monitor changes in gas content. After the reduced iron powder is cooled, it contains CO 2 The passivation gas is used to pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com