High density waterproof composite wooden material and manufacturing method thereof

A technology of wood materials and production methods, which is applied in the field of building materials, can solve problems that do not involve natural plant fibers, and achieve the effects of ensuring human health, high strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

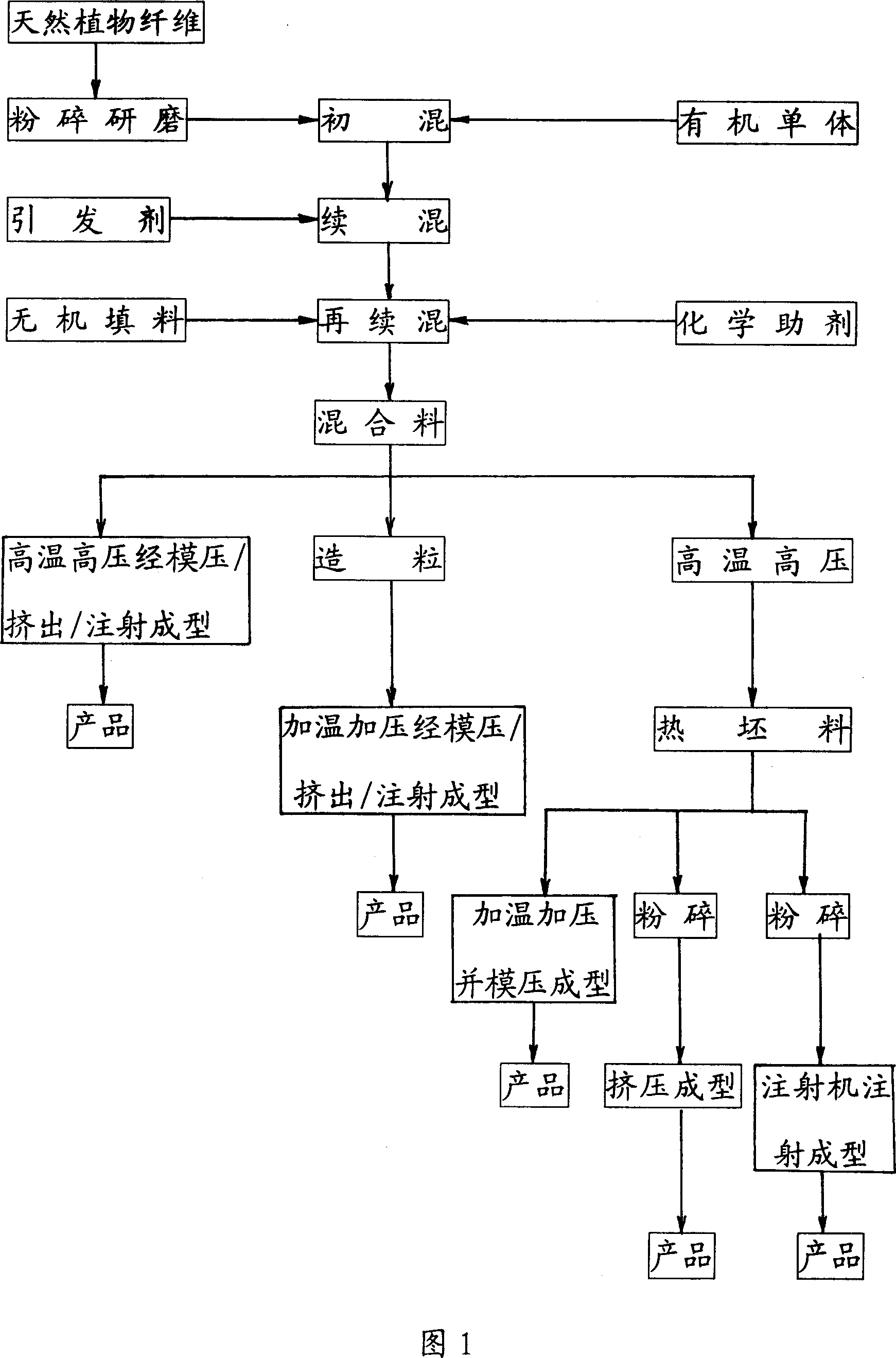

[0072] The high-density water-resistant composite wood material and the manufacturing method of the present invention will be described in detail below in conjunction with the accompanying drawings. As shown in Figure 1 of the manual:

[0073] A high-density water-resistant composite wood material and a production method thereof, using the raw materials for forming the high-density water-resistant composite wood material according to the proportion by weight, according to the following operation steps:

[0074] (1) Prepare the following raw materials according to the following ratio and operation by weight:

[0075] (1). ①. Natural plant fiber: take 85% as 85 kg, grind to a powder with a diameter below 5 mm and get ready for use;

[0076] (1). ②, organic monomer: 5 kg with 5% is ready for use;

[0077] (1). ③. Inorganic filler: 4 kg with 4% is ready for use;

[0078] (1). ④, chemical additives: 4 kg with 4% is ready for use;

[0079] (1). ⑤, initiator: 2 kg is ready for us...

specific Embodiment approach 3

[0090] Carry out by specific implementation mode one, two, just:

[0091] (1) in operation step (1). 1., natural plant fiber: take 20% as 20 kilograms;

[0092] (1) in operation step (1). ②, organic monomer: 60 kilograms with 60%;

[0093] (1) in the operation step (1). ③, inorganic filler: 10.5 kilograms with 10.5%;

[0094] (1) in the operation step (1). 4., chemical auxiliary agent: be 9.45 kilograms with 9.45%;

[0095] (1) in operation step (1). ⑤, initiator: be 0.05 kilogram with 0.05%;

[0096] The rotating speed of stirring blade is 300 revs / min when mixing and stirring in operation step (2);

[0097] (2) in the operation step (2). 1. The mixing and stirring time in the initial stage is 3 minutes;

[0098] (2) in the operation step (2).②, the temperature control is 60°C, and the time for continuing to mix and stir is 3 minutes;

[0099] (2) in the operation step (2).③, the temperature is controlled at 100°C, and the mixing and stirring time is continued for 5 minu...

specific Embodiment approach 4

[0101] Carry out by specific implementation mode one, two, just:

[0102] (1) in operation step (1). 1., natural plant fiber: be 52.5 kilograms with 52.5%;

[0103] (1) in operation step (1). ②, organic monomer: 32.5 kilograms with 32.5%;

[0104] (1) in operation step (1). 3., inorganic filler: be 8.5 kilograms with 8.5%;

[0105] (1) in operation step (1). 4., chemical auxiliary agent: be 5.5 kilograms with 5.5%;

[0106] (1) in the operation step (1). ⑤, initiator: take 1% as 1 kilogram;

[0107] The rotating speed of stirring blade is 1150 rev / mins when mixing and stirring in operation step (2);

[0108] (2) in the operation step (2). 1. The mixing and stirring time in the initial stage is 14 minutes;

[0109] (2).② in the operation step (2), the temperature control is 115°C, and the time for continuing to mix and stir is 9 minutes;

[0110] (2) in the operation step (2).③, the temperature is controlled at 135°C, and the mixing and stirring time is continued for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com