Composite magnetic damping vibration absorber

A composite type and shock absorber technology, which is applied in the direction of spring/shock absorber, magnetic spring, spring, etc., can solve the problems of change, small size, and uncoordinated impact resistance, etc., to achieve improved bearing capacity, low cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

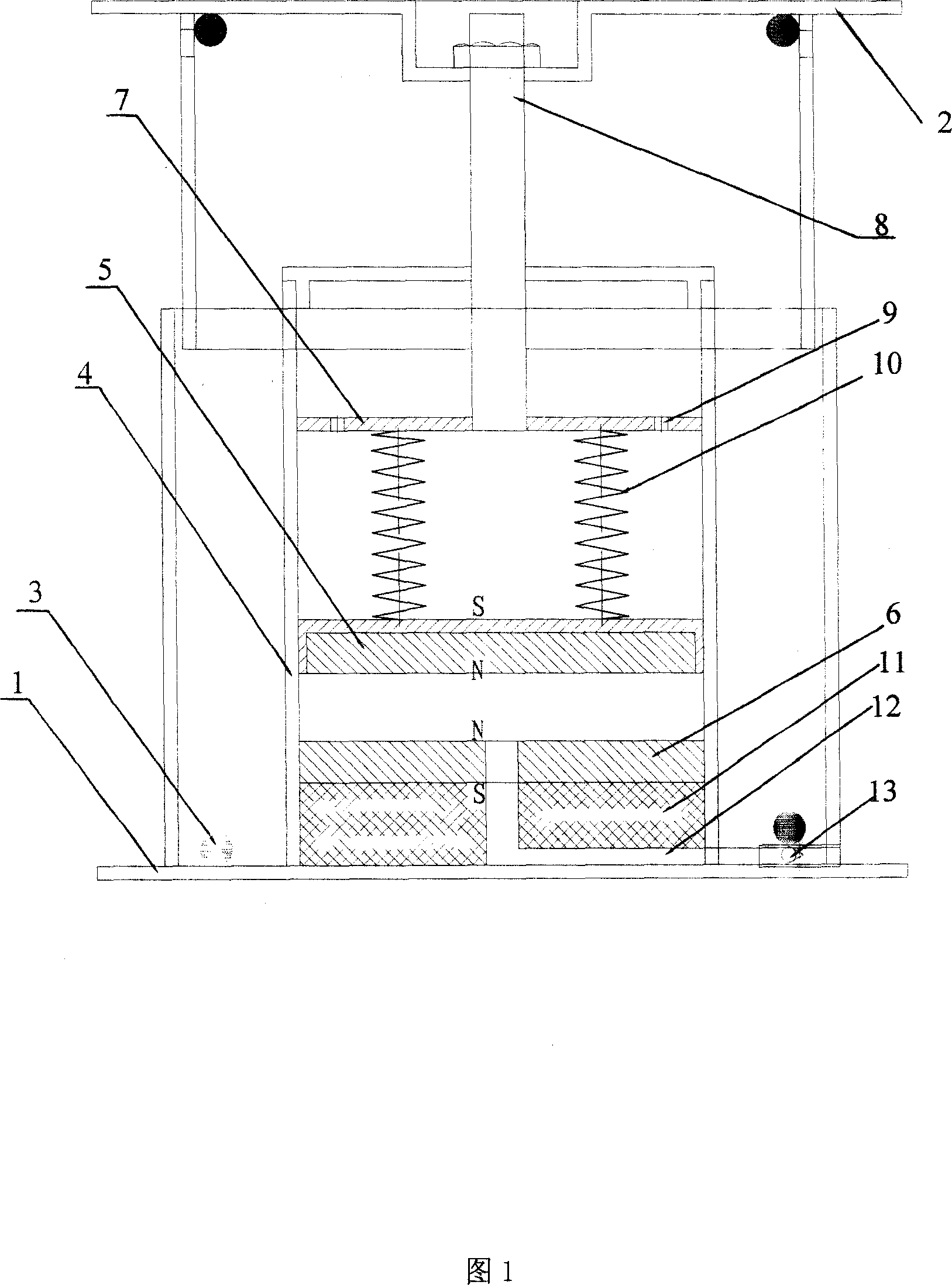

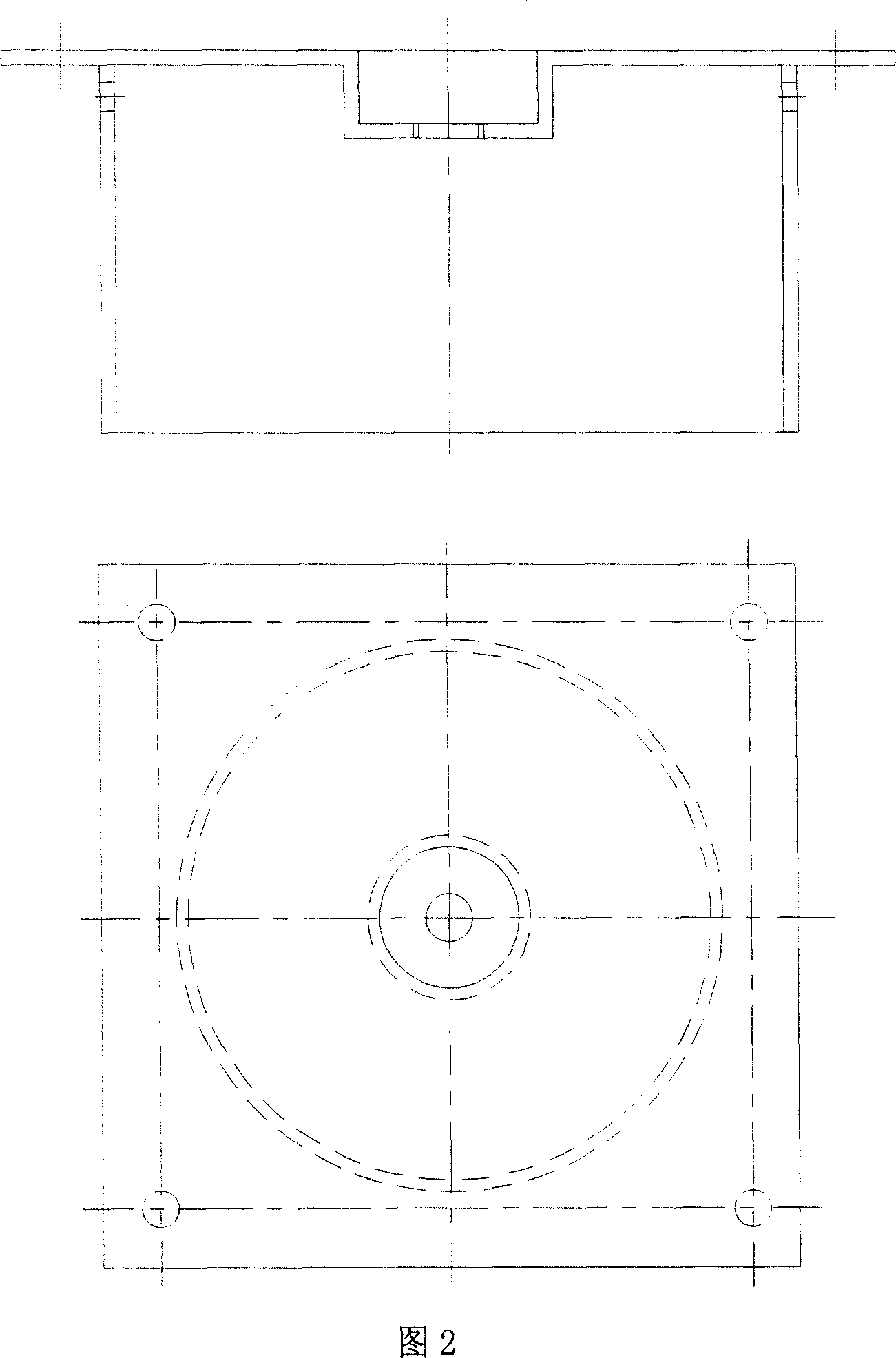

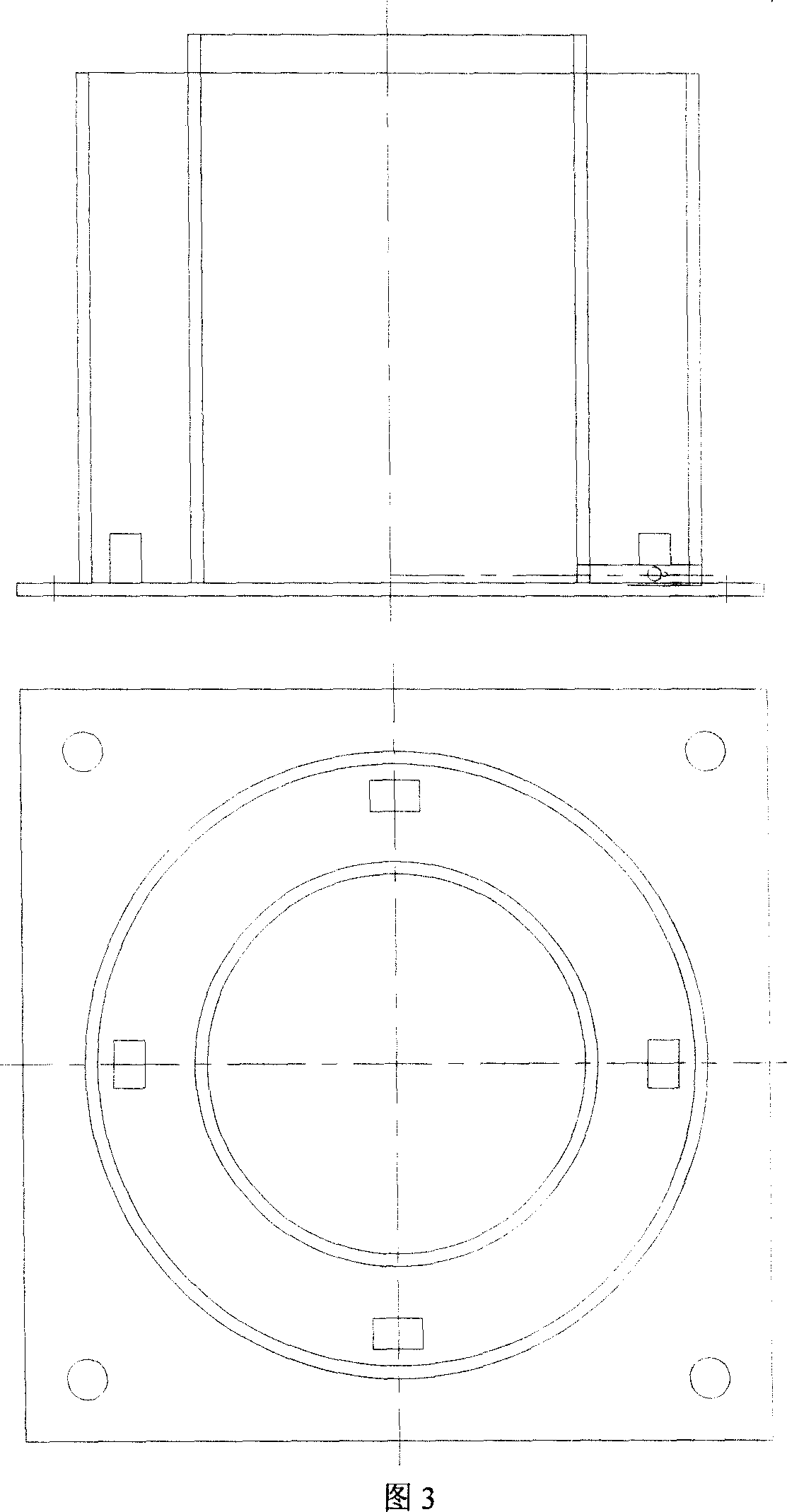

[0016] The composite maglev damping shock absorber includes base plate 1, upper cover 2, main spring 3, cylinder body 4, upper permanent magnet 5, lower permanent magnet 6, piston 7, piston rod 8, damping oil through hole 9, auxiliary spring 10 , rubber pad 11, air duct 12, air valve 13; base plate 1 and upper cover 2 are square, and the side guide plates are cylindrical, the openings of the two containers are opposite, the main spring 3 is placed on the base plate 1, and supports the upper Cover 2, cylinder body 4 is installed on base plate 1, is provided with upper permanent magnet 5 and lower permanent magnet 6 with the same polarity in cylinder body 4, leaves certain gap between two permanent magnets, sets above upper permanent magnet 5 Piston 7 is arranged, and this piston 7 is connected with loam cake 2 through piston rod 8, is provided with secondary spring 10 betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com