Light source even optical fibre low-waste conduction projector

A technology for optical devices and light sources, applied in the directions of light guides, electric light sources, lighting devices, etc., can solve the problems of limited installation location, weak luminous intensity, and reduced optical signal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

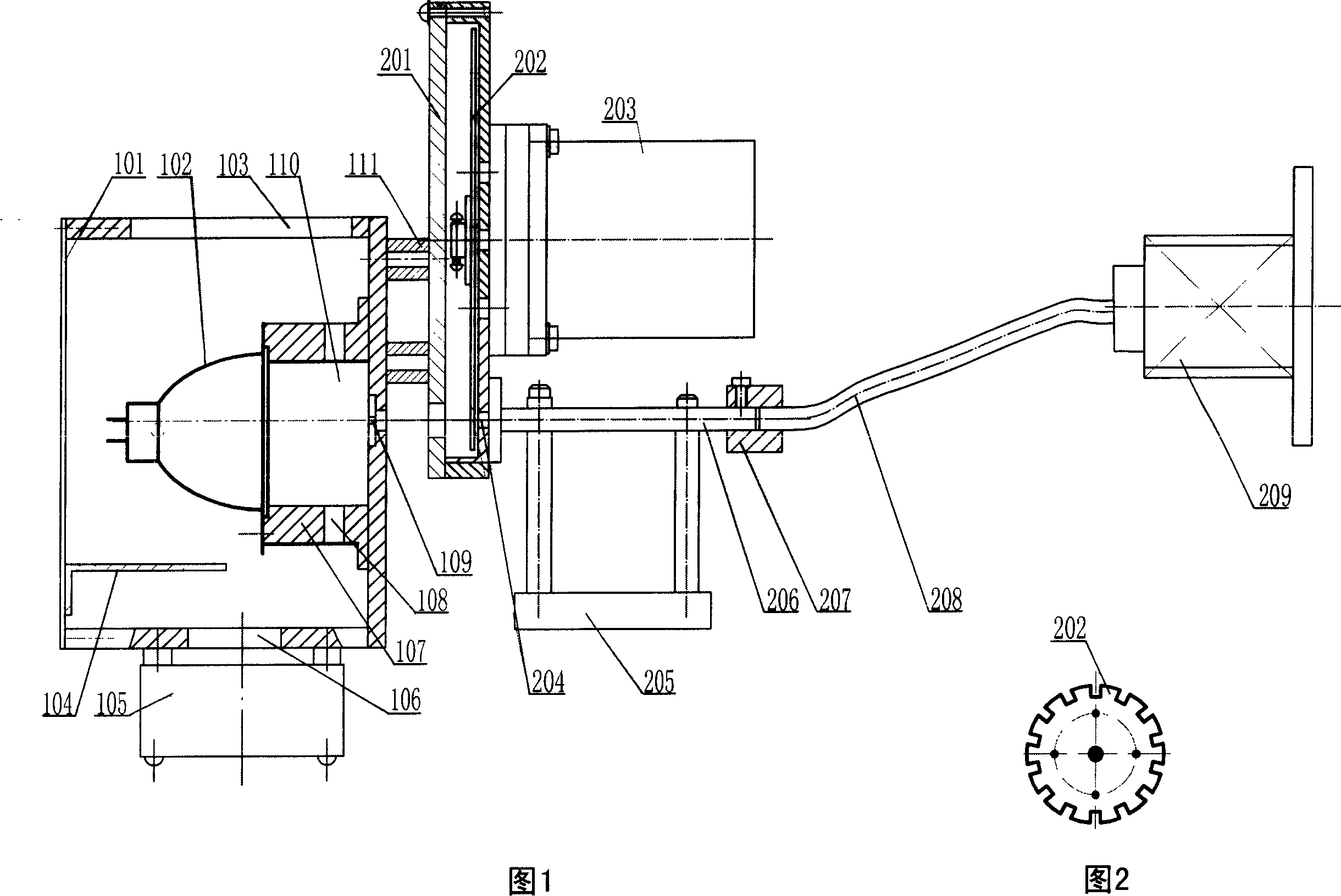

[0014] Referring to Fig. 1 and Fig. 2, the light source uniform light optical fiber low-loss transmission light projection device of the present invention is composed of a light source emission box, a modulator, and a light transmission component, wherein the front wall of the light source emission box 101 is provided with a light source for emitting light beams The exit hole 109 is provided with a high-brightness halogen tungsten lamp 102 capable of producing a strong light source inside. The halogen tungsten lamp 102 is composed of a halogen tungsten lamp, a spotlight cover with an ellipsoid and a lamp holder 107, wherein the lamp holder 107 is fixed on On the front inner wall of the light source emitting box body 101 , the center of the lamp holder 107 is a hollow cavity with a light channel 110 , and communicates with the light source exit hole 109 provided on the front wall of the light source emitting box body 101 . The concentrating surface of the spotlight cover faces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com