Preparing method for organic silicon compound containing quaternary ammonium group

A technology of organosilicon compounds and quaternary ammonium groups, which is applied in the fields of organic chemistry, compounds of Group 4/14 elements of the periodic table, chemical instruments and methods, etc., can solve the problems of many reaction steps, troublesome processing and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 90g (CH 3 O) 2 CH 3 Si(CH 2 ) 3 Add Cl and 200g of diethylamine into a dry reaction kettle, heat to 105°C under stirring, and the pressure is 0.3-0.4Mpa. After 10 hours of reaction, stir and cool down to room temperature, and filter the feed liquid. The filtrate is distilled at atmospheric pressure first, and then decompressed Distillation (71 ~ 72 ℃ / 4mmHg) to obtain 50g intermediate product (CH 3 O) 2 CH 3 Si(CH 2 ) 3 N(C 2 h 5 ) 2 .

Embodiment 2

[0049] 45ml (CH 3 O) 2 CH 3 Si(CH 2 ) 3 Cl and 150ml of diethylamine were added to a four-neck flask equipped with stirring, thermometer, reflux condenser and nitrogen protection device, stirred and heated to 60°C under normal pressure, stirred and cooled to room temperature after 20 hours of reaction, the feed liquid was filtered, and the filtrate was first Atmospheric distillation, and then vacuum distillation (101 ~ 109 ° C / 30mmHg) to obtain 12g intermediate product (CH 3 O) 2 CH 3 Si(CH 2 ) 3 N(C 2 h 5 ) 2 .

Embodiment 3

[0051] In the four-neck flask equipped with thermometer, reflux condenser, dropping funnel and nitrogen protection device, add 10.95g (CH 3 O) 2 CH 3 Si(CH 2 ) 3 N(C 2 h 5 ) 2 and 30g of anhydrous methanol, heated up to 55°C under electromagnetic stirring, slowly added dropwise 5.6g of epichlorohydrin, and reacted for 4 hours to obtain the organosilicon compound containing quaternary ammonium groups (CH 3 O) 2 CH 3 Si(CH 2 ) 3 N + (C 2 h 5 ) 2 CH 2 CHOCH 2 Cl - methanol solution, methanol was distilled off, washed several times with anhydrous ether and then vacuum-dried to obtain a light yellow transparent quaternary ammonium salt product. The chloride ion content was 90.12% and the epoxy value was 70.99% as measured by silver nitrate titration.

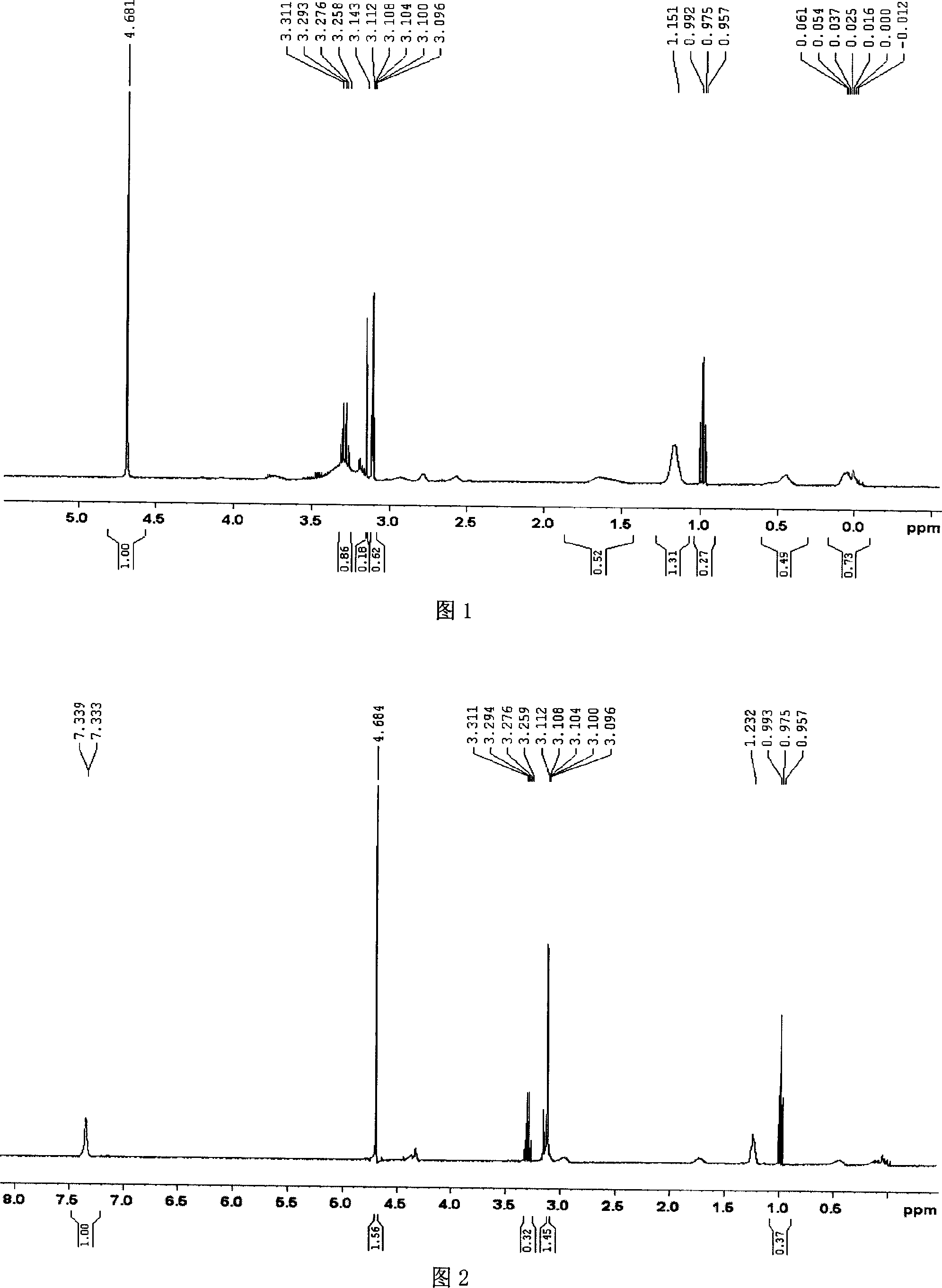

[0052] Accompanying drawing 1 is this compound 1 H-NMR spectrum, the corresponding chemical shifts are: 0.419ppm for -Si-C H 3 peak, the triplet at 0.974ppm is -Si-C H 2 -C peak, 1.648ppm for -C-C H 2 -C-peak,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com