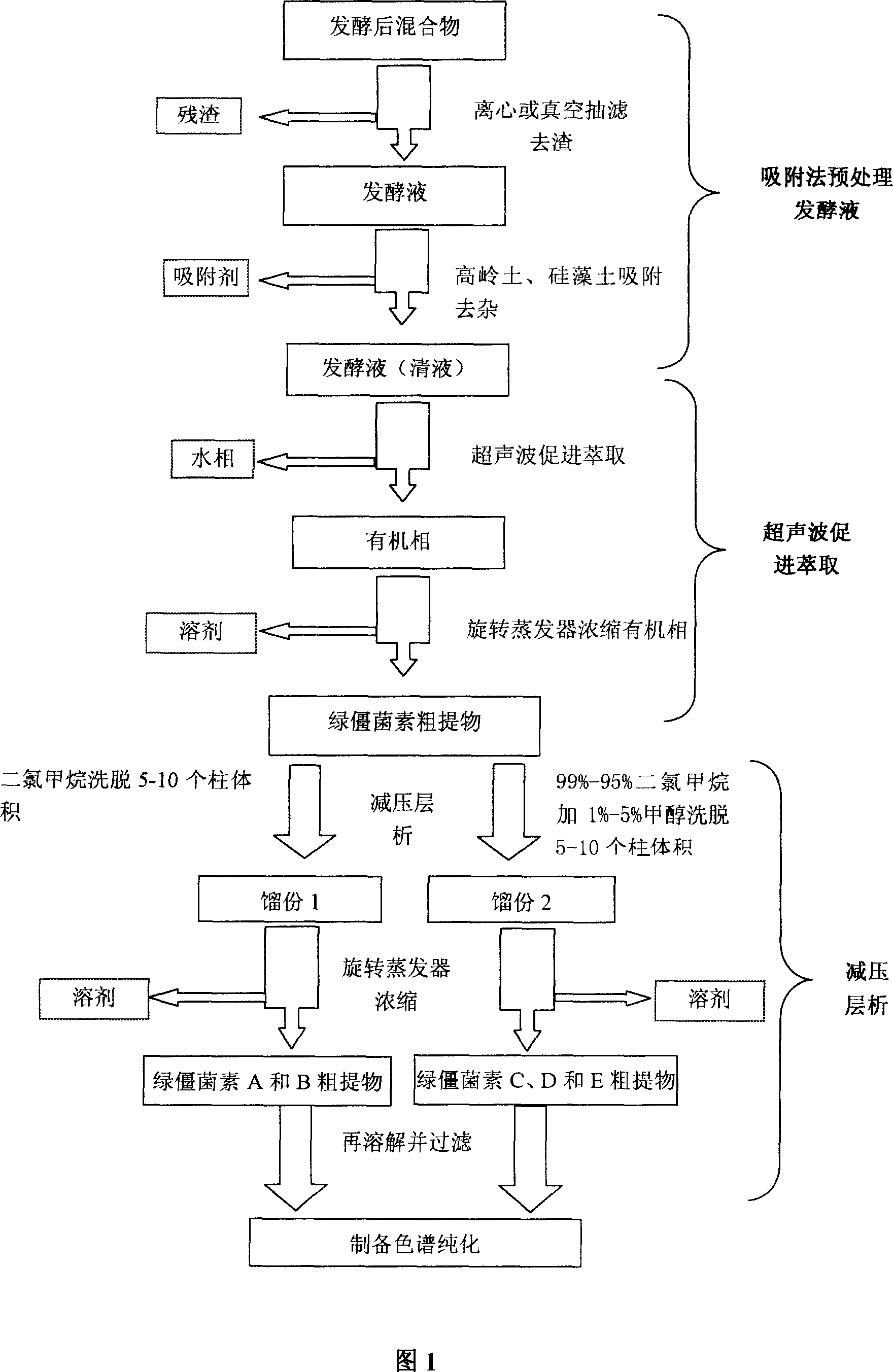

Method of separating and purifying destruxins of Metarrhizium anisopliae

A technology for the separation and purification of metarhizin, which is applied in the field of separation and purification, can solve the problems of high preparation cost, achieve the effects of reducing preparation cost, reducing the amount of solvent, and saving metarhizin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

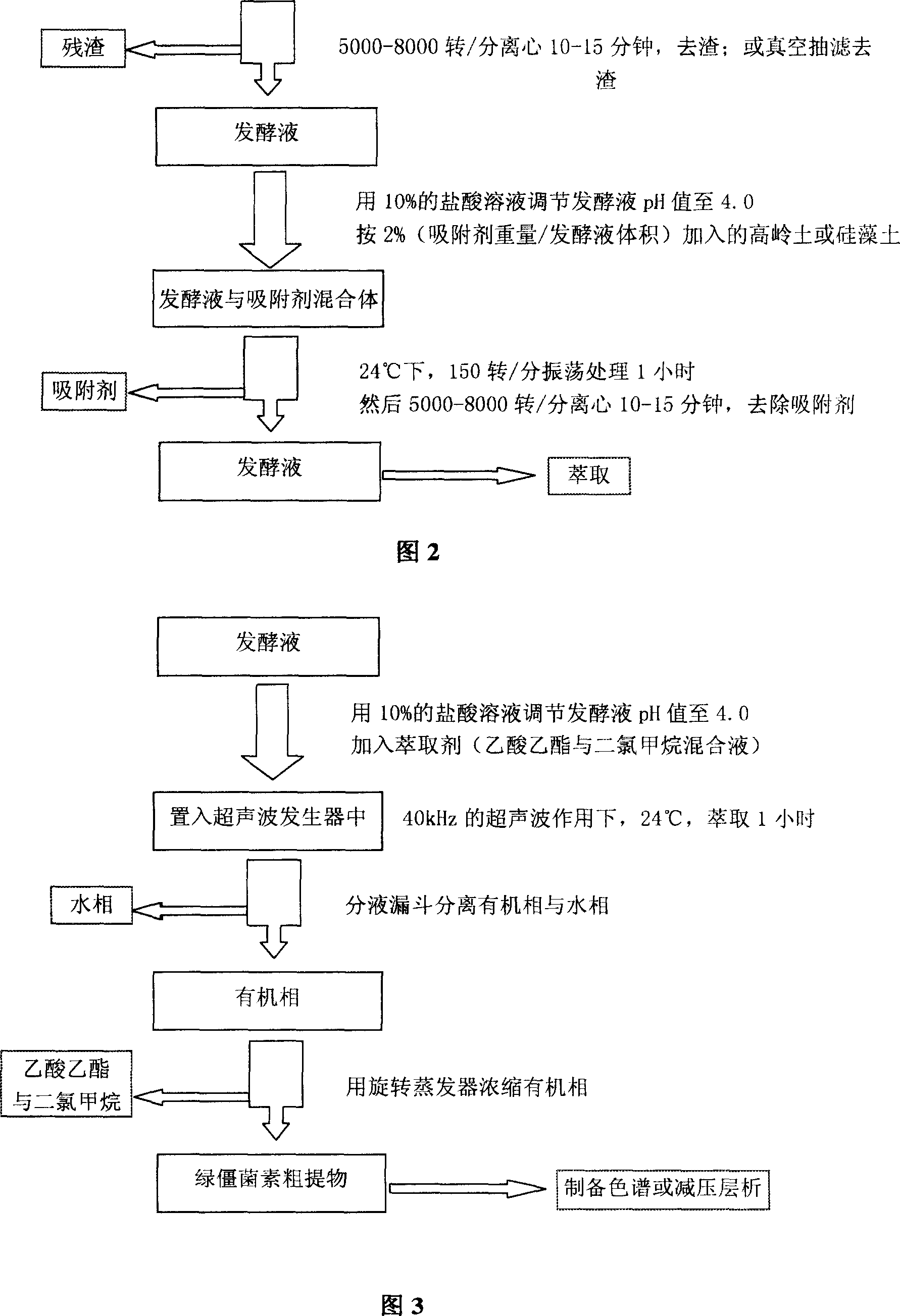

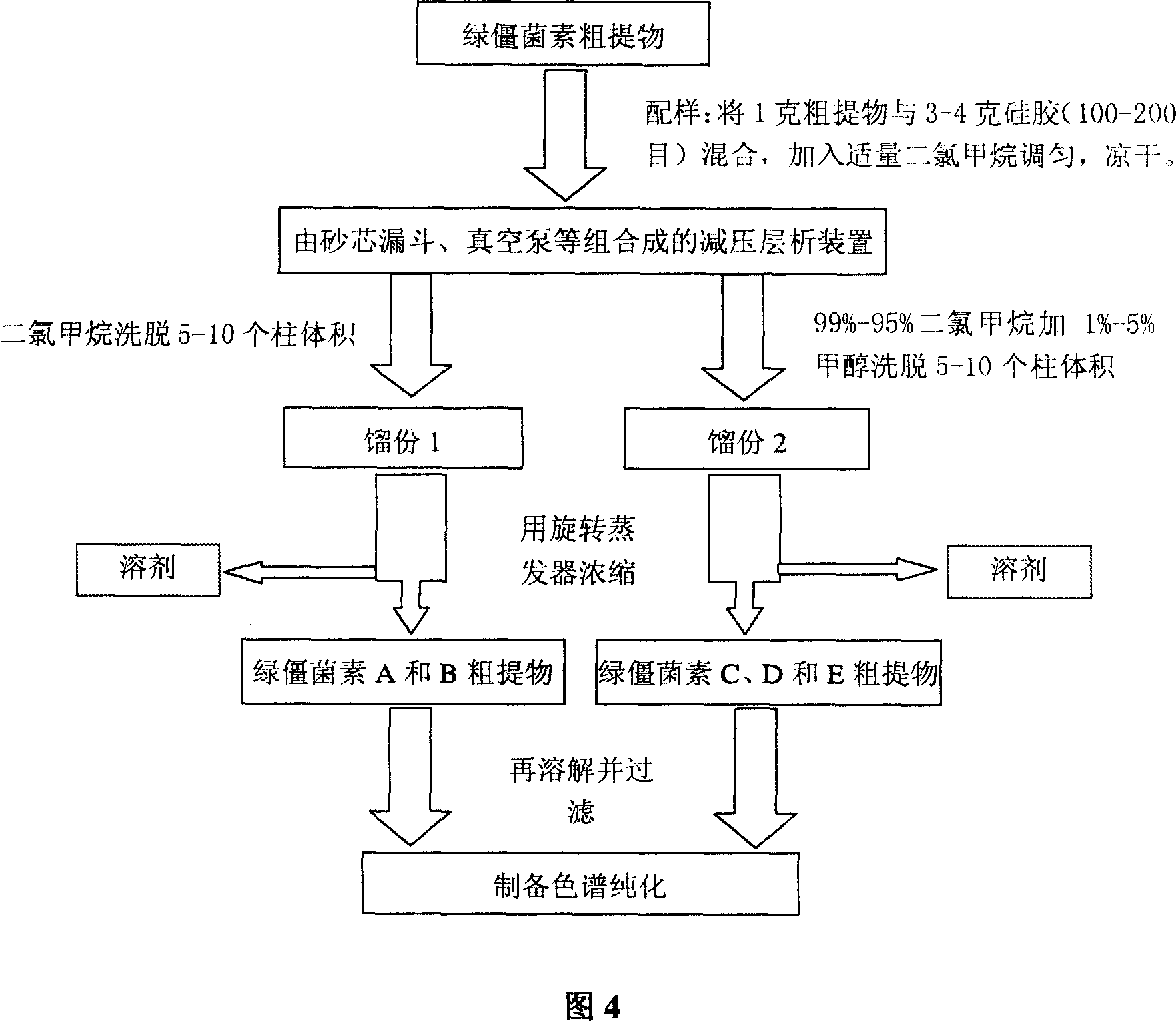

[0024]After fermenting the liquid produced from Metarhizium anisopliae var.anisopliae, centrifuge it with a centrifuge at 5000-8000 rpm for 10-15 minutes to remove the slag; or vacuum filter to remove the slag; 10% hydrochloric acid solution to adjust the pH value of the fermentation broth to 4.0, use kaolin or diatomaceous earth as an adsorbent, and add it to the fermentation broth according to the weight of the adsorbent / volume of the fermentation broth = 2%, at 24 ° C, 150 rpm Oscillating the adsorption place for 1 hour; then centrifuging with a centrifuge at 5000 to 8000 rpm for 10 to 15 minutes to remove the adsorbent and retain the fermentation broth, as shown in Figure 2; use 10% hydrochloric acid solution to adjust the pH value of the fermentation broth to 4.0, the extraction solvent is a mixture of the following volume ratios: ethyl acetate: dichloromethane = 1: 1; the volume ratio of the extraction solvent to the fermentation broth is 50: 50; the ultrasonic wave with ...

Embodiment 2

[0026] Repeat the same steps as described in Example 1, but the conditions of adsorption method pretreatment of fermentation broth, ultrasonic wave to promote extraction, and preparative chromatographic separation and purification process are respectively changed to:

[0027] (1) Conditions for pretreatment of fermentation broth by adsorption method:

[0028] Use 10% hydrochloric acid solution to adjust the pH value of the fermentation broth to 3.0-6.0; the adsorbent is kaolin, diatomaceous earth, bentonite, or a mixture of one or both of them; the amount of adsorbent: adsorbent weight / fermentation broth volume = 1-5%; temperature: 15-35°C; oscillating speed: 100-200 rpm; adsorption treatment for 0.5-2 hours.

[0029] (2) Conditions for ultrasonic-promoted extraction:

[0030] Use 10% hydrochloric acid solution to adjust the pH value of the fermentation broth to 3.0-6.0; the extraction solvent is a mixed solution of the following volume ratio: ethyl acetate: dichloromethane=4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com