A high temperature super-conduct inductor, its preparing method and its application in the high-voltage power

A high-temperature superconducting and inductive technology, applied in the field of electronics, can solve problems such as unavailability, high voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

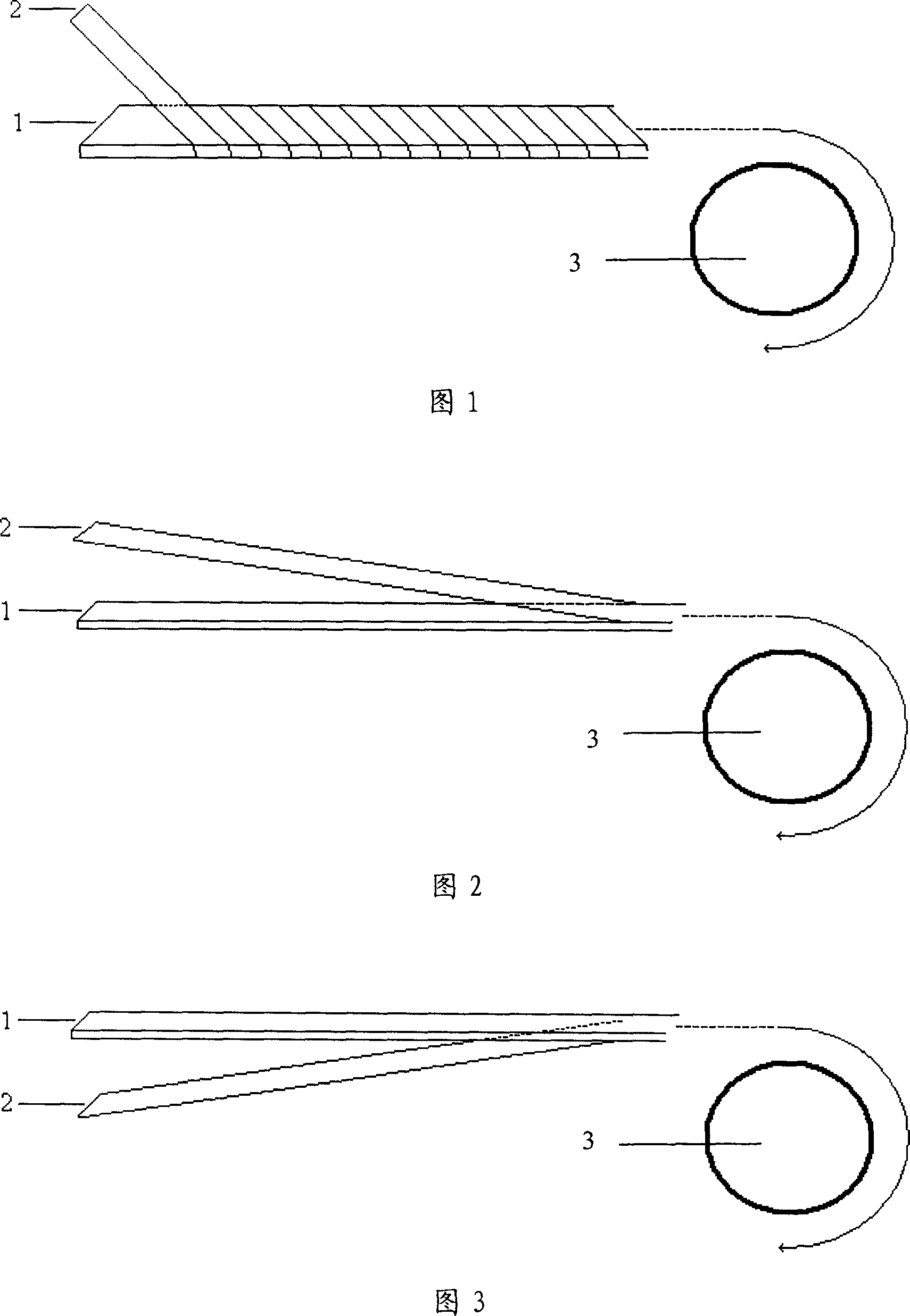

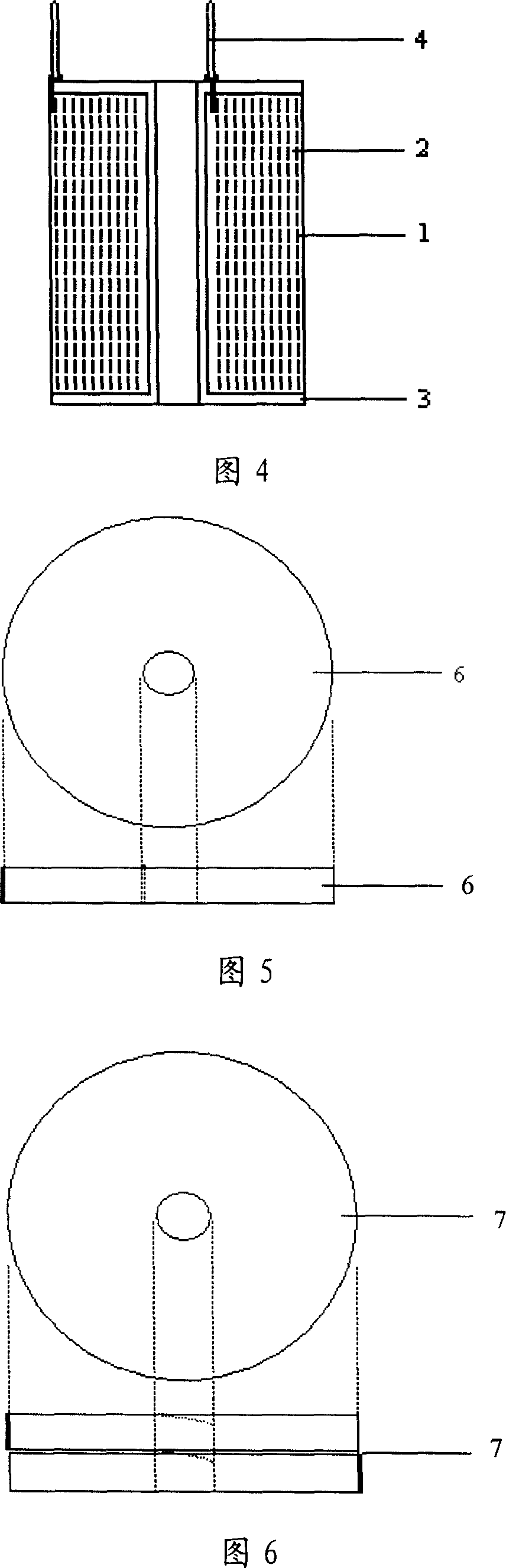

Embodiment 1

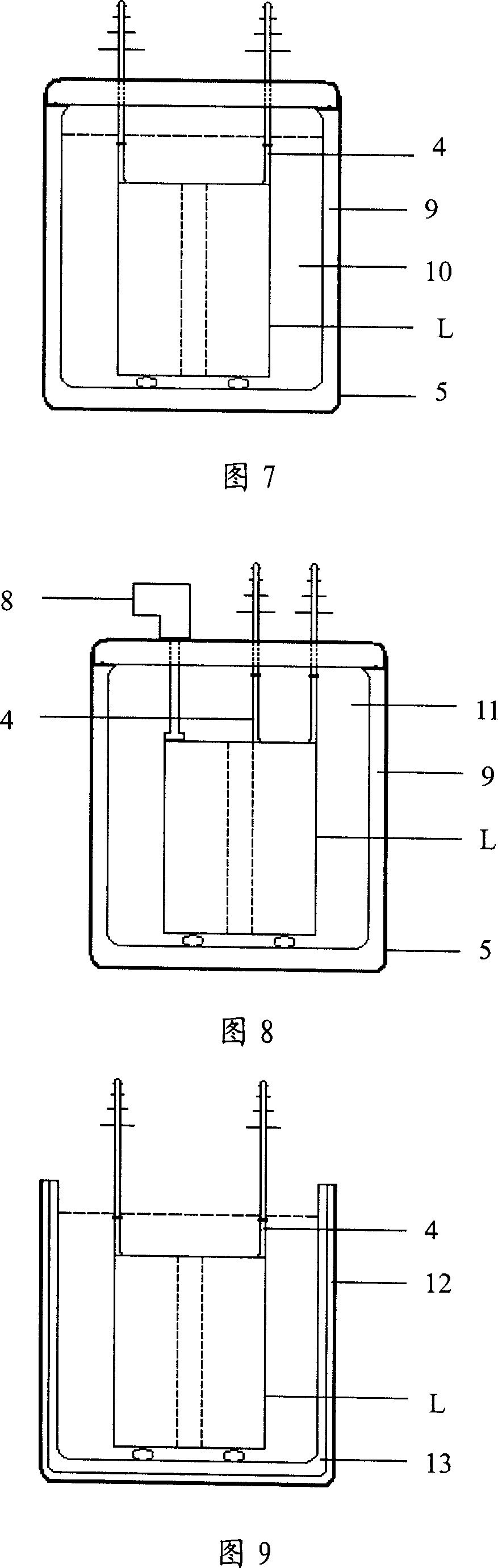

[0041] As shown in Figure 1, Figure 4, Figure 8, Figure 10, and Figure 11. Select (Bi, Pb) prepared by powder tube technology 2 Sr 2 Ca 2 Cu 3 o 10+x (T c ~110K) single multi-core metal-clad wire is used as a high-temperature superconducting wire 1. The high temperature superconducting wire 1 is insulated and wrapped with an insulating tape 2, which is a Capton film tape with an epoxy resin film. The high-temperature superconducting wire 1 after the insulation treatment is wound by an automatic winding machine, that is, the coil frame 3 is wound in a solenoid type, and wound in three layers; the material of the coil frame 3 is Bakelite. The wound coil is subjected to vacuum high-temperature treatment, that is, curing treatment, and then the coil of the high-temperature superconducting inductor L is obtained. The produced high temperature superconducting inductor L has a high temperature superconducting inductor current lead 4, which is composed of one high temperature s...

Embodiment 2

[0044] As shown in Figure 1, Figure 4, Figure 7, Figure 10, and Figure 11. The place identical with embodiment 1 no longer repeats narration, and difference is:

[0045] Select (Bi, Pb) prepared by powder tube technology 2 Sr 2 Ca 2 Cu 3 o 10+x (T c~110K) single-core metal-clad wire as a high-temperature superconducting wire 1. The high-temperature superconducting wire 1 after the insulation treatment is wound by an automatic winding machine, that is, the coil frame 3 is wound in a solenoid type, and a total of one layer is wound. The prepared high-temperature superconducting inductor L is placed in a Dewar low-temperature box 5, and cooled with a refrigerant 10. In the Dewar low-temperature box 5, the high-temperature superconducting inductor L is surrounded by liquid argon; the Dewar low-temperature box The material of 5 is non-metallic fiberglass, has vacuum insulation interlayer 9.

[0046] The prepared high-temperature superconducting inductor L is applied to a hi...

Embodiment 3

[0048] As shown in Figure 2, Figure 6, and Figure 7. Select (Bi, Pb) prepared by powder tube technology 2 Sr 2 Ca 1 Cu 2 o 8-x (T c ~85K) three multi-core metal-clad wires are used in parallel as a high-temperature superconducting wire 1. The high-temperature superconducting wire 1 is insulated, that is, when the high-temperature superconducting wire 1 is wound, an insulating tape 2 is added above the high-temperature superconducting wire 1, and the insulating tape 2 is a Capton film tape. The winding of the high-temperature superconducting wire 1 is carried out by a manual winding machine, and double-cake winding is carried out on the coil bobbin 3, that is, the high-temperature superconducting wire 1 which has been insulated is used, and the midpoint is the symmetrical point, without breaking the high-temperature superconducting wire 1. Under the condition of the superconducting wire 1, it is reversely wound to form a double-cake-type high-temperature superconducting i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com