A making method of the contact hole plug and layer 1 metal

A manufacturing method and contact hole technology, which are used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increased plug resistance, defective semiconductor devices, and easy formation of voids, so as to improve production efficiency and reduce interconnection. Resistance, the effect of reducing manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

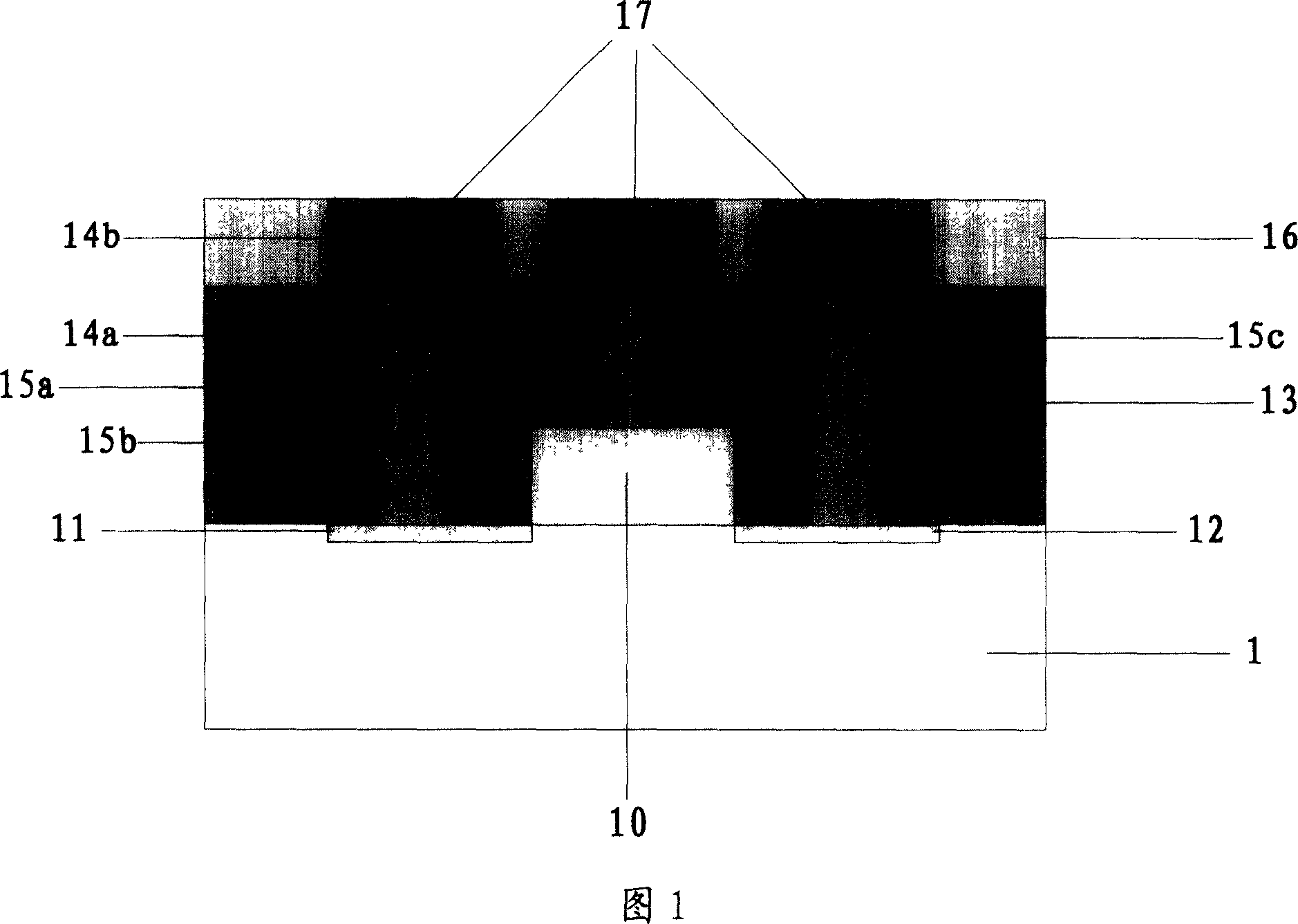

[0023] The method for manufacturing the contact hole plug and the first layer metal of the present invention will be further described in detail below.

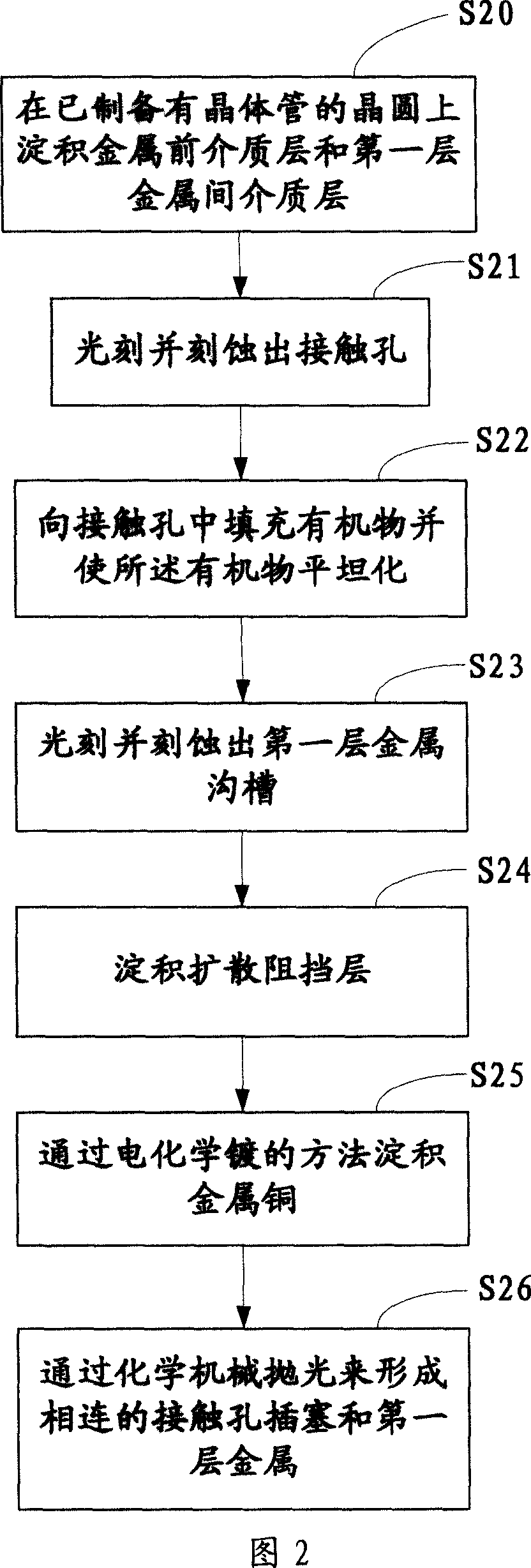

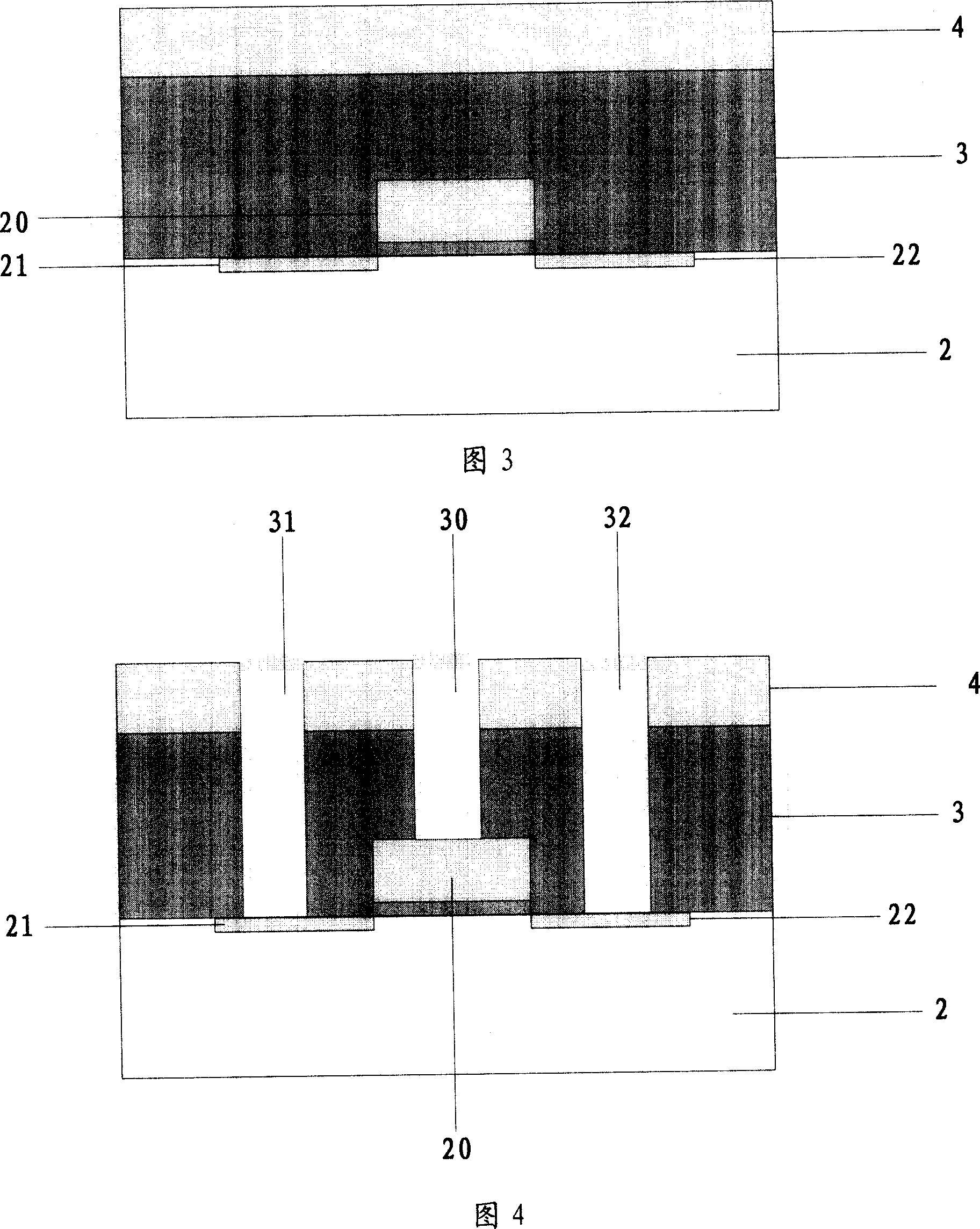

[0024] Referring to FIG. 2, the method for manufacturing the contact hole plug and the first layer of metal of the present invention first performs step S20, depositing a pre-metal dielectric layer and a first layer of intermetallic dielectric layer on the wafer prepared with transistors, wherein, The pre-metal dielectric layer and the first intermetal dielectric layer are made of different materials. In this embodiment, the metal pre-dielectric layer is firstly deposited on the wafer prepared with transistors by chemical vapor deposition, then chemical mechanical polishing is performed on the metal pre-dielectric layer, and finally the metal pre-dielectric layer is deposited on the wafer by chemical vapor deposition. A first intermetal dielectric layer is deposited on the pre-metal dielectric layer. Referring to FIG. 3 , it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com