Use of bismuth oxyhalide

A bismuth oxyhalide and photocatalytic technology, which is applied in the fields of dye degradation, photolysis of water to produce hydrogen, bactericidal materials, degradation of organic harmful gases, and photocatalytic materials. It can solve the problems of low quantum yield, photochemical corrosion, and poor photocatalytic activity of powders. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Bi 2 o 3 The powder is dissolved in the corresponding concentrated halogen acid, adjusted to pH = 3 with dilute ammonia water, and filtered several times until no X is detected - After ions (tested with silver nitrate solution), the precipitate is dried at 80°C to obtain the finished nano photocatalytic powder.

[0042] The specific process of the loaded BiOX (X=Cl, Br, I) photocatalytic material can be: take 2g of BiOX (X=Cl, Br, I) catalyst powder and put it into a beaker containing 100ml of deionized water, add 10ml of methanol Hole sacrificial agent and appropriate amount of AgNO 3 or H 2 PtCl 6 ·6H 2 O, under a 300W mercury lamp for 85-10 hours while vigorously stirring, after several times of filtration, washing, and drying, the photocatalytic material loaded with nano-Ag or Pt particles can be obtained.

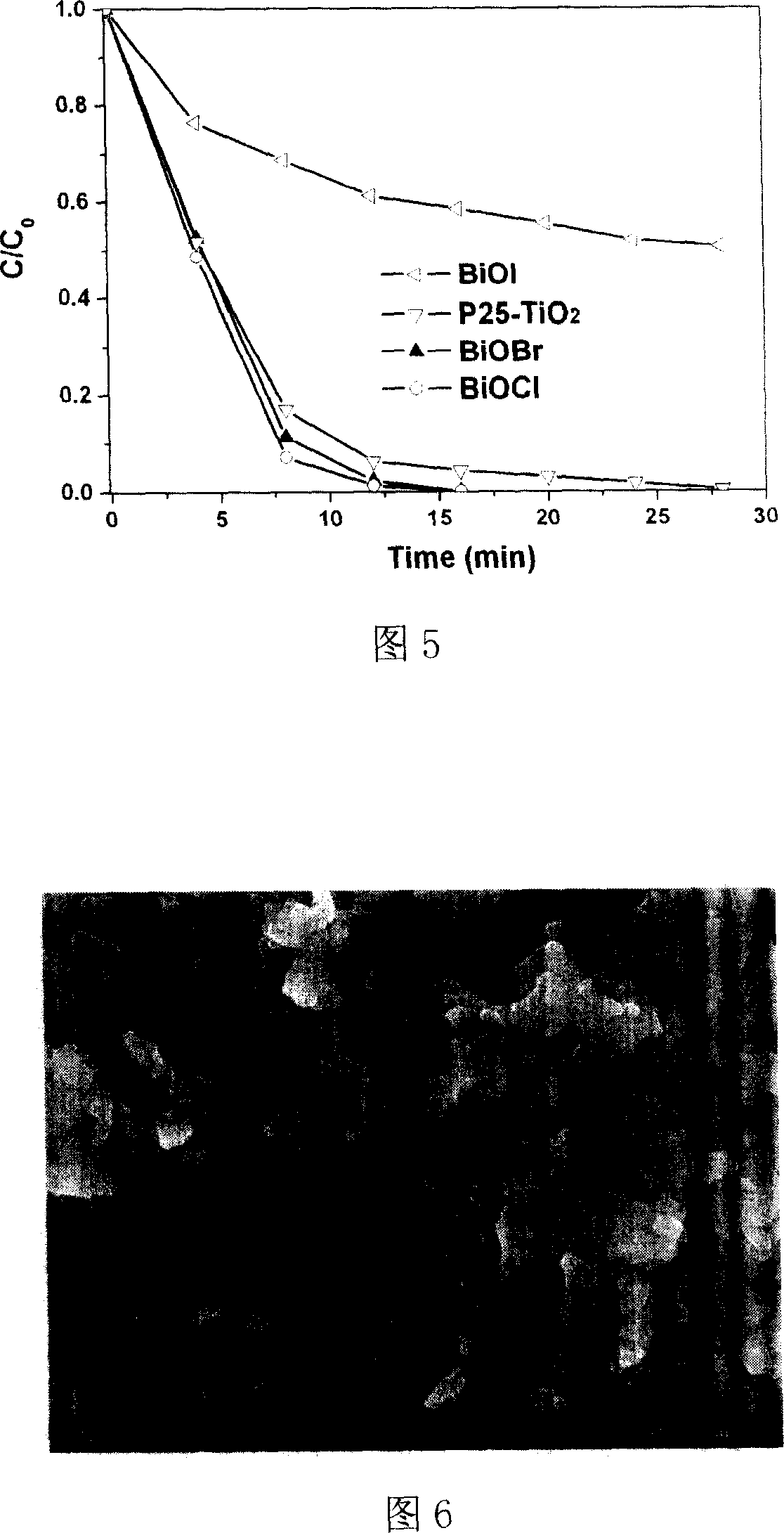

[0043] The experiment of photocatalytic degradation of organic substance methyl orange shows that the UV photocatalytic performance of BiOX (X=Cl, Br) is ...

Embodiment 2

[0048] Bi of the stoichiometric ratio 2 o 3 and BiX 3 (X=Cl, Br, I) was placed in a quartz tube, vacuumized and packaged, and heated at 550° C. for 12 hours. After cooling, open the tube and grind to get the finished photocatalytic powder.

[0049] Photocatalytic degradation of dye methyl orange, photolysis of water to produce hydrogen, degradation of harmful substance formaldehyde and bactericidal test results are about 40% of those in Embodiment 1, which may be due to the smaller specific surface area of the sample prepared by the same phase method.

Embodiment 3

[0051] Take 100ml of deionized water in a beaker, use the corresponding halogen acid to adjust the pH of the solution to less than 1, then heat the solution to about 70°C, while stirring continuously, slowly add 1mol of bismuth nitrate-halogen acid solution, and at the same time slowly add 15% NaOH solution to neutralize the HNO produced by hydrolysis 3 , maintain the pH value at around 2, and the whole process lasts for about 1 hour. During this period, the temperature was kept constant at about 75°C, continued to stir for 10 minutes, cooled, filtered, washed, and dried at 80°C to obtain the finished photocatalytic powder.

[0052] The performance test result is basically the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com