Process of deoxygenating, desulfurizing and controlling non-metal inclusion content in steel

A technology for desulfurization of non-metallic inclusions and molten iron, used in desulfurization, high-strength alloy structural steel, deoxidation, control of non-metallic inclusions in steel, and the production of steel grades, it can solve the problem of high oxygen content in steel and reduce total oxygen content, high desulfurization ability, and the effect of preventing secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

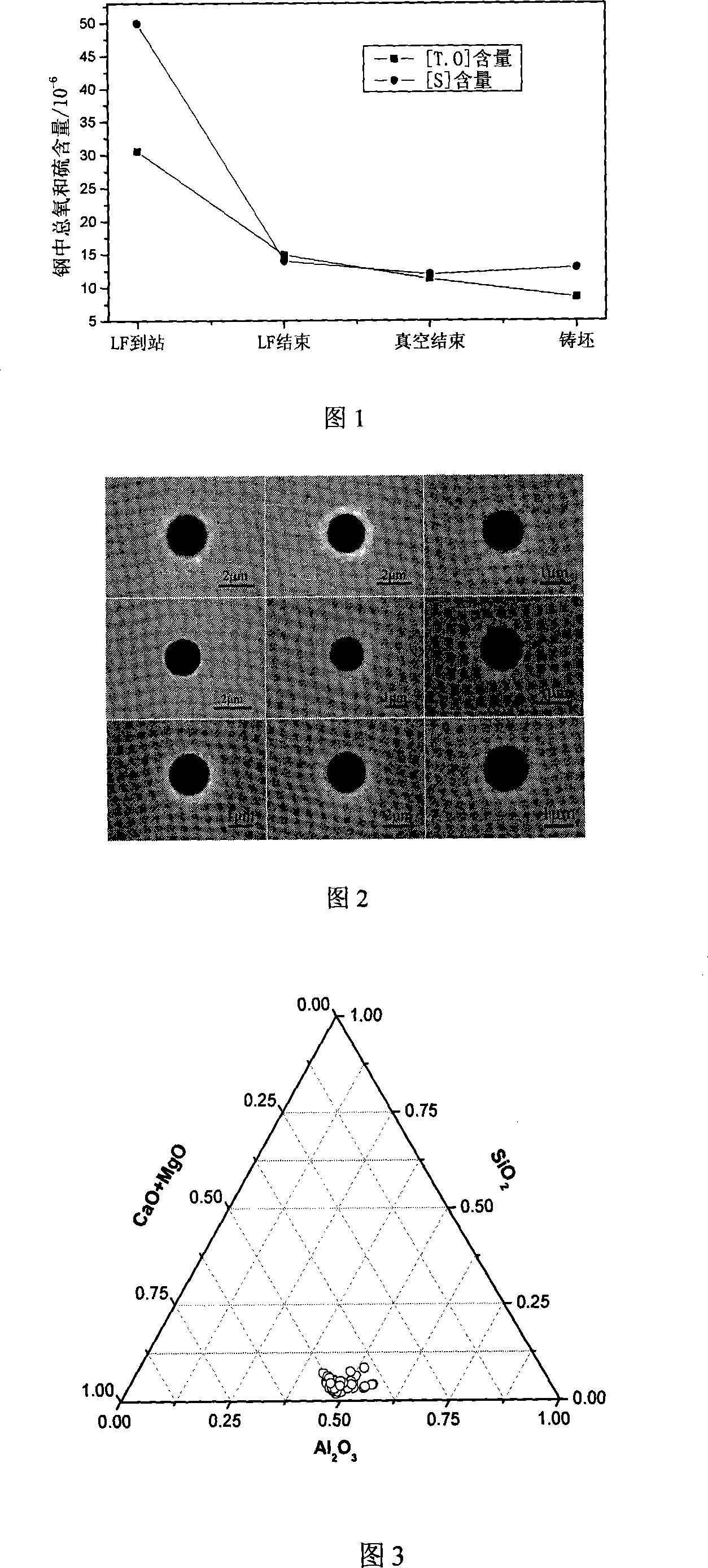

[0013] Test steel 42CrMo (chemical composition weight percentage (%): C: 0.38 ~ 0.45, Si: 0.17 ~ 0.37, Mn: 0.50 ~ 0.80, Mo: 0.15 ~ 0.25, Cr: 0.90 ~ 1.20, P < 0.035, S < 0.035 ).

[0014] (1) Pour 143 tons of molten iron into the converter, molten iron [S] = 0.014%, [P] = 0.08%, [C] = 3.75%, T = 1345 ° C, add active lime 7862Kg, high Mg lime 3654Kg to start blowing Refining, converter blowing time is 29min, end point of blowing [C]=0.12%, [P]=0.008%, [S]=0.008%, T=1696℃, final slag basicity 5. Converter tapping strictly prevents slag, and uses a large tank with a clean bottom to hold molten steel. Add 80Kg of aluminum shot at the beginning of tapping, and then add 80Kg of aluminum shot when tapping 1 / 3, and add 170Kg of carbon powder and 55Kg of low-aluminum ferrosilicon. , 875Kg silicon manganese, 1950Kg ferrochromium, 300Kg ferromolybdenum, 90Kg aluminum shot is added when tapping 2 / 3, the tapping time is 5min, the slag thickness at the end of tapping is 60mm, and the cleara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com