Silver-electrolyzing catalyst composition and silver-electrolyzing catalyst bed

A catalyst bed, electrolytic silver technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of large gas resistance, short service life of catalysts, and poor thermal conductivity To achieve the effect of slowing down the resistance rise of the catalytic layer and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation process of the crystalline electrolytic silver used will be described below. Crystalline electrolytic silver adopts a one-time electrolysis process, and the specific process steps are as follows:

[0027] In the electrolytic cell, the polar plate (with holes of 5mm evenly distributed on the plate) made of acid-resistant alloy steel or titanium plate is used as the anode, and the silver block of No. GB4135-2002IC-Ag99.99 is used as the raw material for the anode, so that the concentration is 10 %, Fe 3+ The AgNO3 electrolyte with a content of ≤20mg / L undergoes oxidation-reduction reaction at a current density of 50A / dm2 and a voltage of 10V. The electrolysis temperature is 35°C, and granular electrolytic silver precipitates on the cathode plate and falls off automatically. deposited on the bottom of the electrolytic cell;

[0028] Regularly fish out the granular electrolytic silver, and when it reaches a certain weight, immerse it in distilled water to ...

Embodiment 1

[0031] Below with diameter be 1800mm, the oxidizer that produces 50,000 tons of formaldehyde per year is an example to illustrate the concrete laying process of electrolytic silver catalyst bed of the present invention:

[0032] 1. Prepare catalyst layer raw materials according to the following weight ratio:

[0033] 40 mesh fiber silver catalyst 8kg,

[0034] 32 mesh fiber silver catalyst 25kg

[0035] 24 mesh crystalline silver catalyst 20kg

[0036] 16 mesh crystalline silver catalyst 27kg

[0037] 8 mesh crystalline silver catalyst 30kg

[0038] The weight ratio of the fibrous silver catalyst to the crystalline silver catalyst is 30:70.

[0039] 2. Lay the catalyst bed:

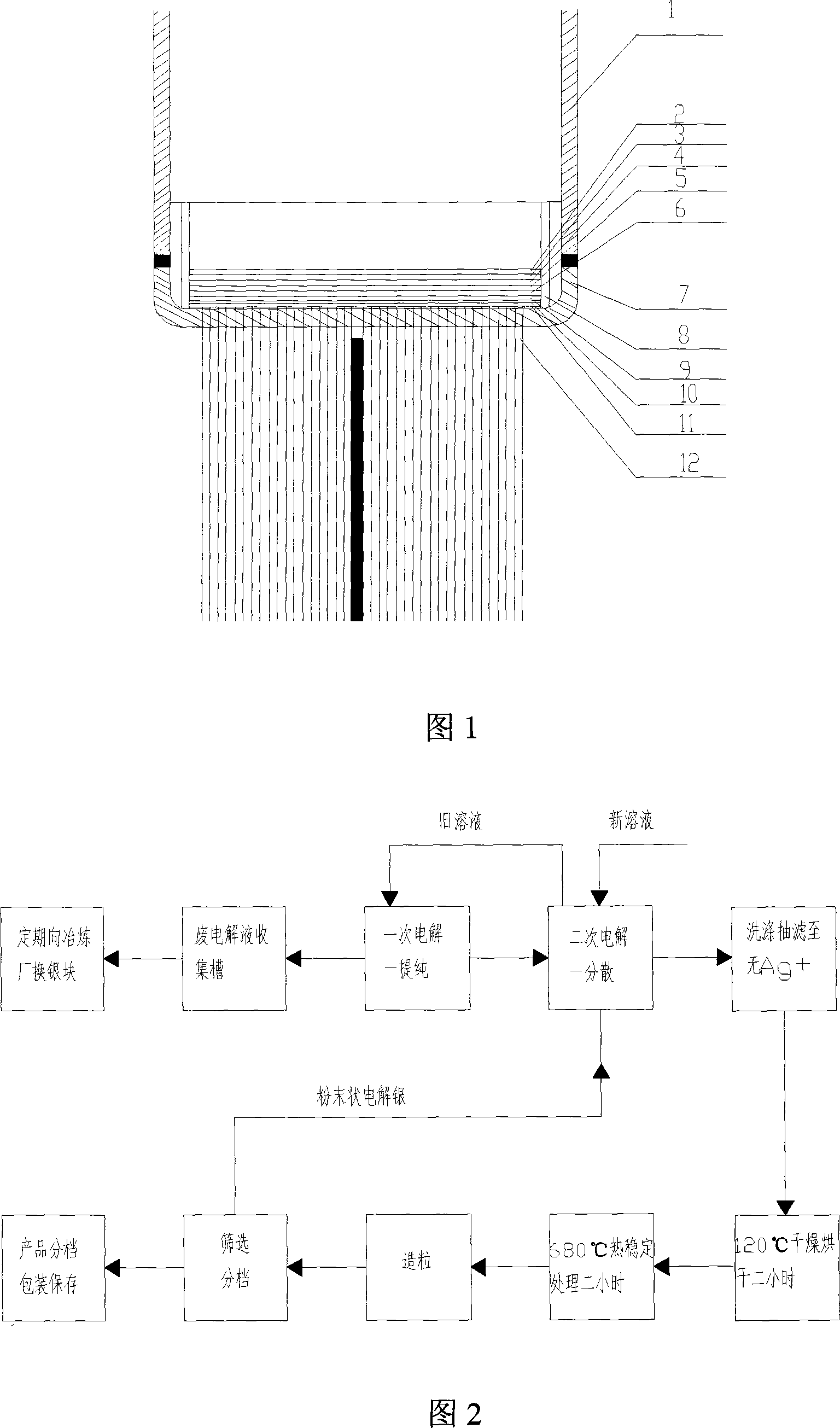

[0040] As shown in Figure 1, a catalyst support cylinder 8 is placed on the upper tube plate 7 of the oxidation reactor, and stainless steel wires are laid layer by layer on the upper surface of the upper tube plate 7 surrounded by the inner cylindrical surface of the support cylinder 8. Net 11, 8 m...

Embodiment 2

[0042]Adopt the oxidizer identical with embodiment one, lay electrolytic silver catalyst bed of the present invention according to the following steps:

[0043] 1. Prepare the raw materials for each catalyst layer according to the following weight ratio:

[0044] 40 mesh fiber silver catalyst 7kg

[0045] 32 mesh fiber silver catalyst 20.5kg

[0046] 24 mesh crystalline silver catalyst 22.5kg

[0047] 16 mesh crystalline silver catalyst 30kg

[0048] 8 mesh crystalline silver catalyst 30kg

[0049] The weight ratio of the fibrous silver catalyst to the crystalline silver catalyst is 25:75.

[0050] 2. Lay the catalyst bed:

[0051] The specific steps are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com