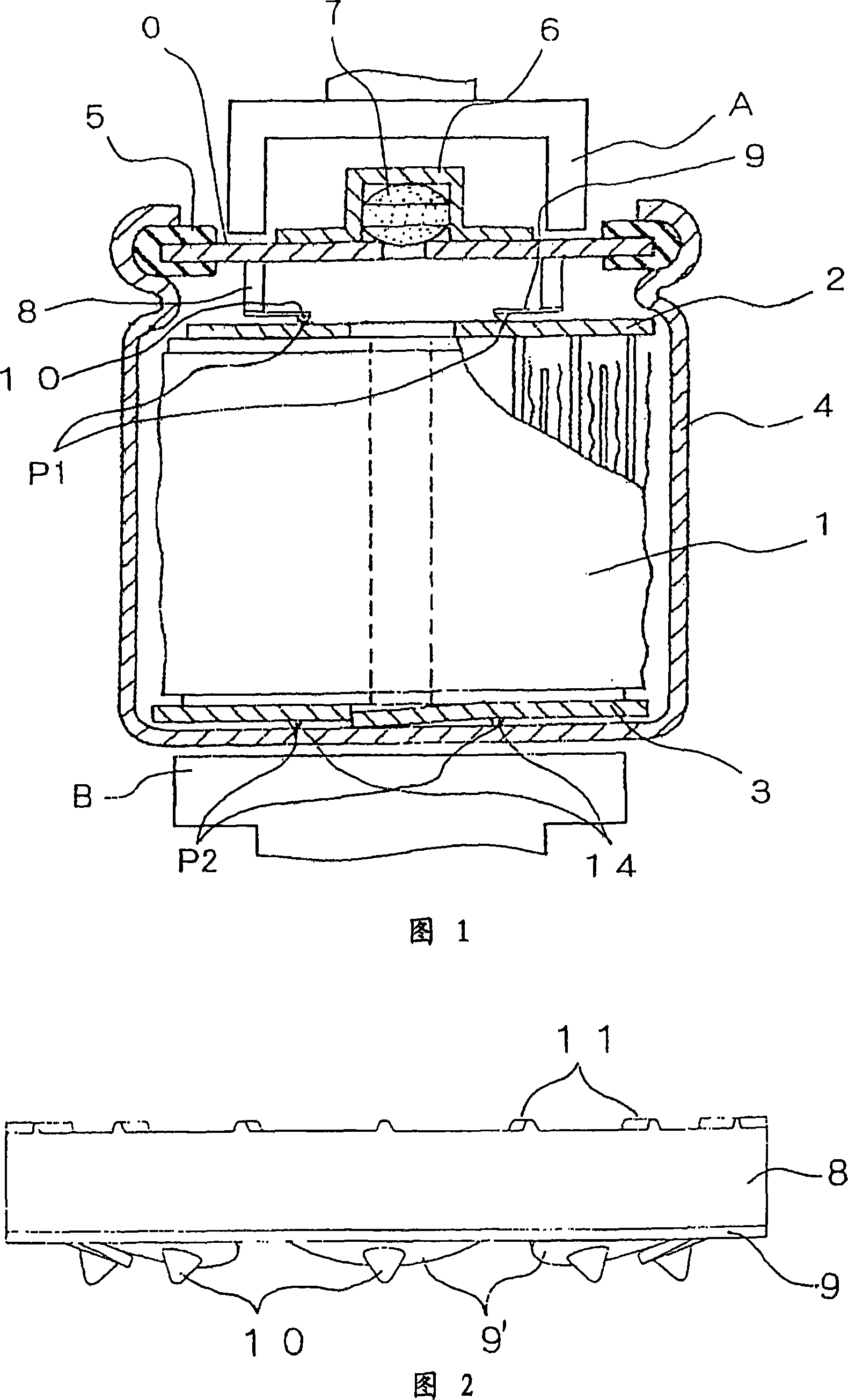

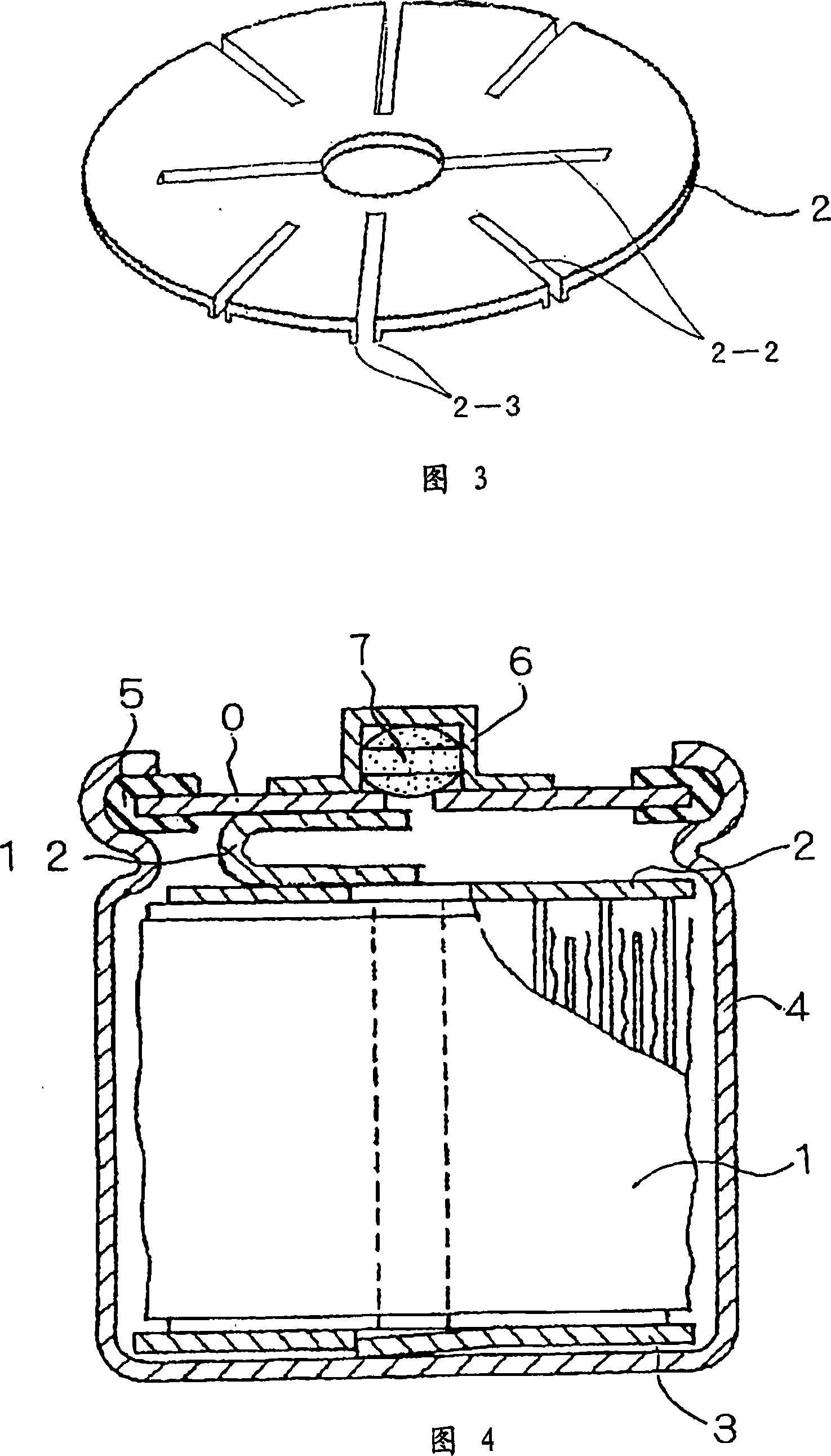

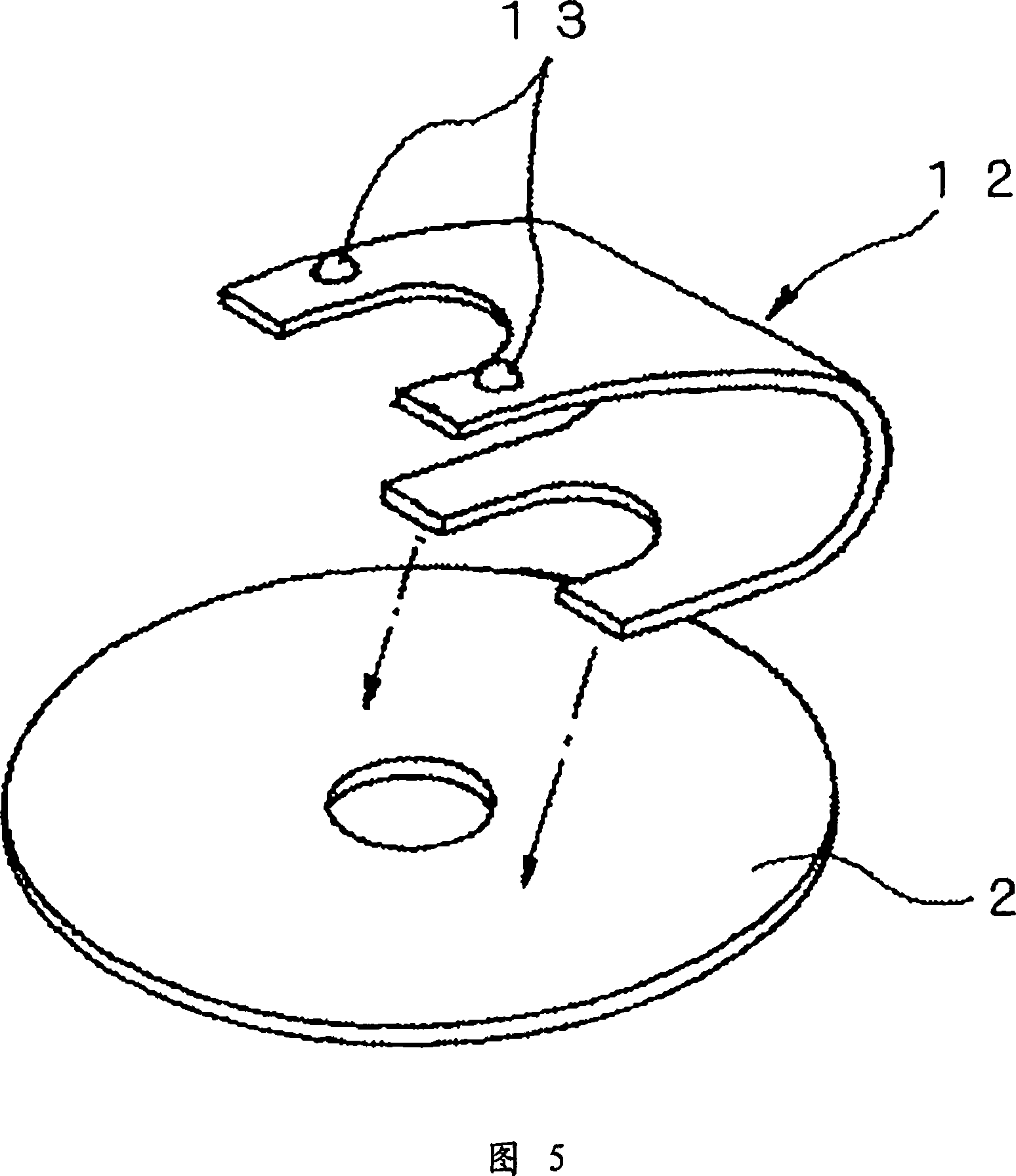

Hydrogen storage electrode and nickel hydrogen battery

A nickel-metal hydride battery and electrode technology, applied in battery electrodes, battery pack parts, alkaline battery electrodes, etc., can solve the problems of high resistance of current collector leads and low battery output characteristics, and achieve excellent anti-corrosion effect and efficient discharge. characteristics, the effect of excellent charge-discharge cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] (Surface modification treatment of hydrogen storage alloy powder)

[0133] (Pretreatment: hydrogen storage)

[0134] Under reduced pressure, 100°C for AB with an average particle size of 30 μm 5 MmNi 3.55 co 0.6 al 0.3 mn 0.35 The composed hydrogen storage alloy was heat-treated for 10 hours, and put into a hydrogen atmosphere with a hydrogen partial pressure of 0.1 MPa and a temperature of 60° C. for 15 minutes to store hydrogen.

[0135] (1st process: dipping treatment)

[0136] Using the NaOH aqueous solution 11 at a temperature of 100° C. and a concentration of 45% by weight as a treatment solution, 1 kg of the hydrogen storage alloy powder after the hydrogen storage treatment above was subjected to an impregnation treatment. The dipping treatment time was 52 minutes. During the immersion treatment, the treatment solution was stirred so that the hydrogen storage alloy powder would not settle. Here, during the immersion treatment, control was performed such t...

Embodiment 2

[0154] A monopolar battery was produced in the same manner as in Example 1 except that in the step of surface modifying the hydrogen storage alloy powder (first step: dipping treatment), the immersion treatment time was set to 1.3 hours, and the discharge capacity was measured. Take this embodiment as embodiment 2.

Embodiment 3

[0156] A monopolar battery was produced in the same manner as in Example 1 except that in the step of surface modifying the hydrogen storage alloy powder (first step: dipping treatment), the immersion treatment time was set to 1.8 hours, and the discharge capacity was measured. Take this embodiment as embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com