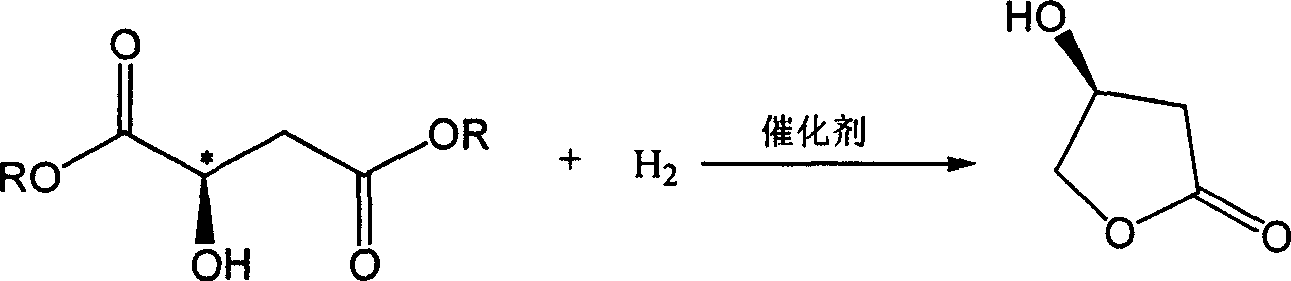

Method for synthetizing (S)3-hydroxy-gamma-butyrolactone by L-malate dioester catalytic hydrogenation

A malic acid diester, catalytic hydrogenation technology, applied in the direction of organic chemistry, etc., can solve the problems of difficult product purification, waste generation, and separation of butyrolactone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, the synthesis of catalyst:

[0018] 2.0 g of RhCl[Ph 2 PCH 2 CH 2 Si(OC 2 h 5 ) 3 ] 3 (Rh-P) complex, 50 mL of toluene and 10 g of SiO 2 Supported palladium catalyst (Pd-SiO 2 , Pd content is 10wt%) placed in the reaction flask, reflux reaction under nitrogen protection for 5 hours, filtered, the filter cake was washed three times with toluene, and dried to obtain the homogeneous-heterogeneous composite catalyst Rh-P / Pd-SiO 2 . By a similar method, respectively, with SiO 2 Supported nickel, platinum and ruthenium catalysts (Ni-SiO 2 , Pt-SiO 2 , Ru-SiO 2 ) instead of supported palladium catalyst Pd-SiO 2 , the composite catalyst Rh-P / Ni-SiO can be prepared 2 , Rh-P / Pt-SiO 2 and Rh-P / Ru-SiO 2 .

Embodiment 2~5

[0019] Embodiments 2 to 5, hydrogenation catalytic reaction: 0.5 gram of the composite catalyst obtained in Example 1, 10 gram of L-dimethyl malate and 50 milliliters of tetrahydrofuran were added in a pressure reactor, and after the reactor was replaced by hydrogen, the The mixture was stirred and reacted under 120 atmospheres of hydrogen at 100° C. for 24 hours. The catalyst was separated from the reaction mixture by filtration, and the filtrate was analyzed by chromatography. The results are shown in Table 1.

[0020] catalyst

Embodiment 6

[0025] Embodiment 6, the synthesis of catalyst:

[0026] 1.5 g of RhCl[Ph 2 PCH 2 CH 2 Si(OC 2 h 5 ) 3 ] 3 (Rh-P) complex, 50 mL of toluene and 10 g of SiO 2 Supported palladium catalyst (Pd-SiO 2 , Pd content is 5wt%) is placed in the reaction flask, reflux reaction under nitrogen protection for 5 hours, filtered, the filter cake is washed three times with toluene, and dried to obtain the homogeneous-heterogeneous composite catalyst Rh-P / Pd-SiO 2 . By a similar method, respectively, with SiO 2 Supported nickel, platinum and ruthenium catalysts (Ni-SiO 2 , Pt-SiO 2 , Ru-SiO 2 ) instead of supported palladium catalyst Pd-SiO 2 , the composite catalyst Rh-P / Ni-SiO can be prepared 2 , Rh-P / Pt-SiO 2 and Rh-P / Ru-SiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com