System for measuring and analyzing digital-controlled machine-tool dynamic characteristic

A dynamic characteristic, CNC machine tool technology, applied in the testing of machine/structural components, metal processing equipment, metal processing machinery parts, etc., can solve the problems of economic loss, low CNC processing efficiency, and restricting the development of the national defense industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

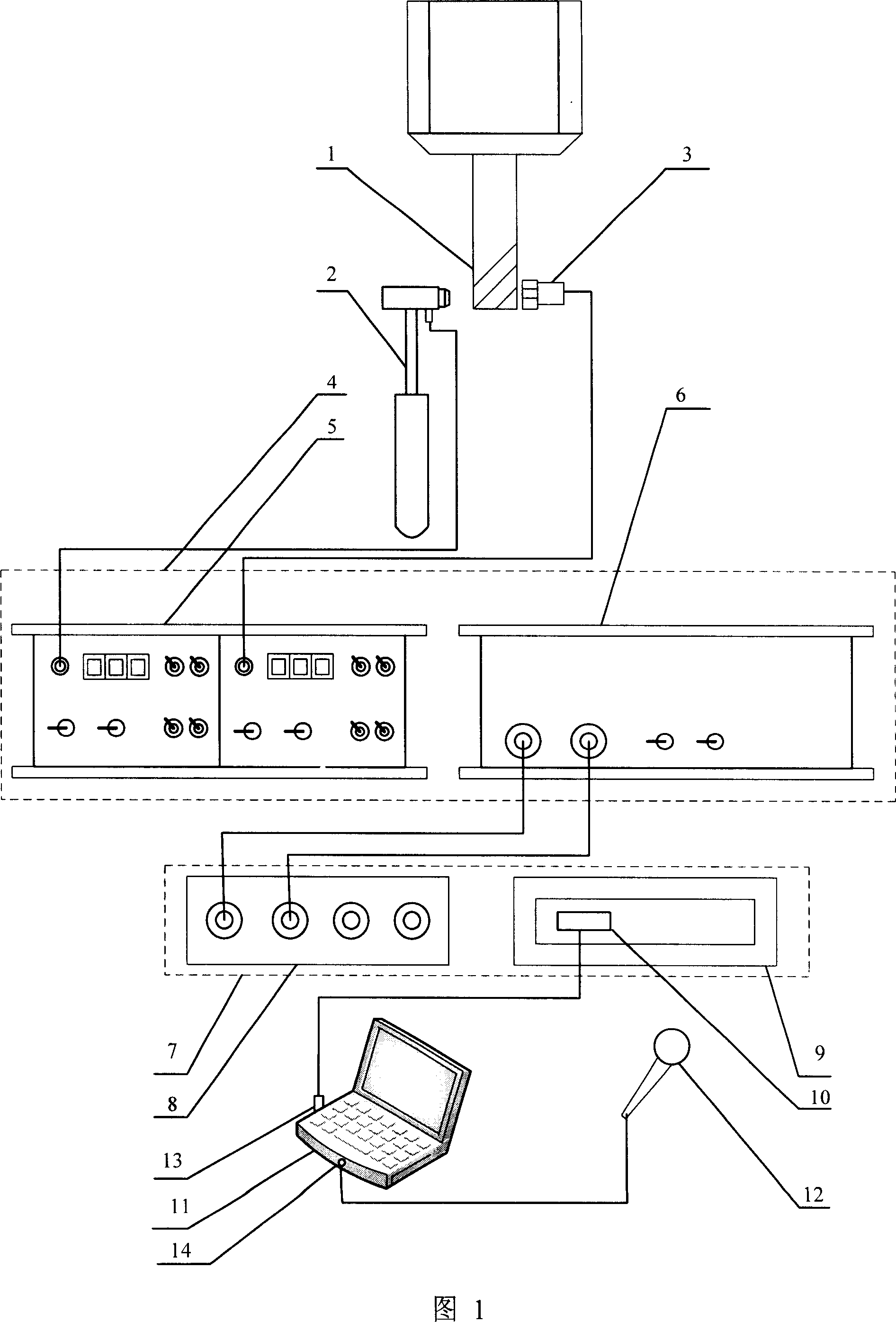

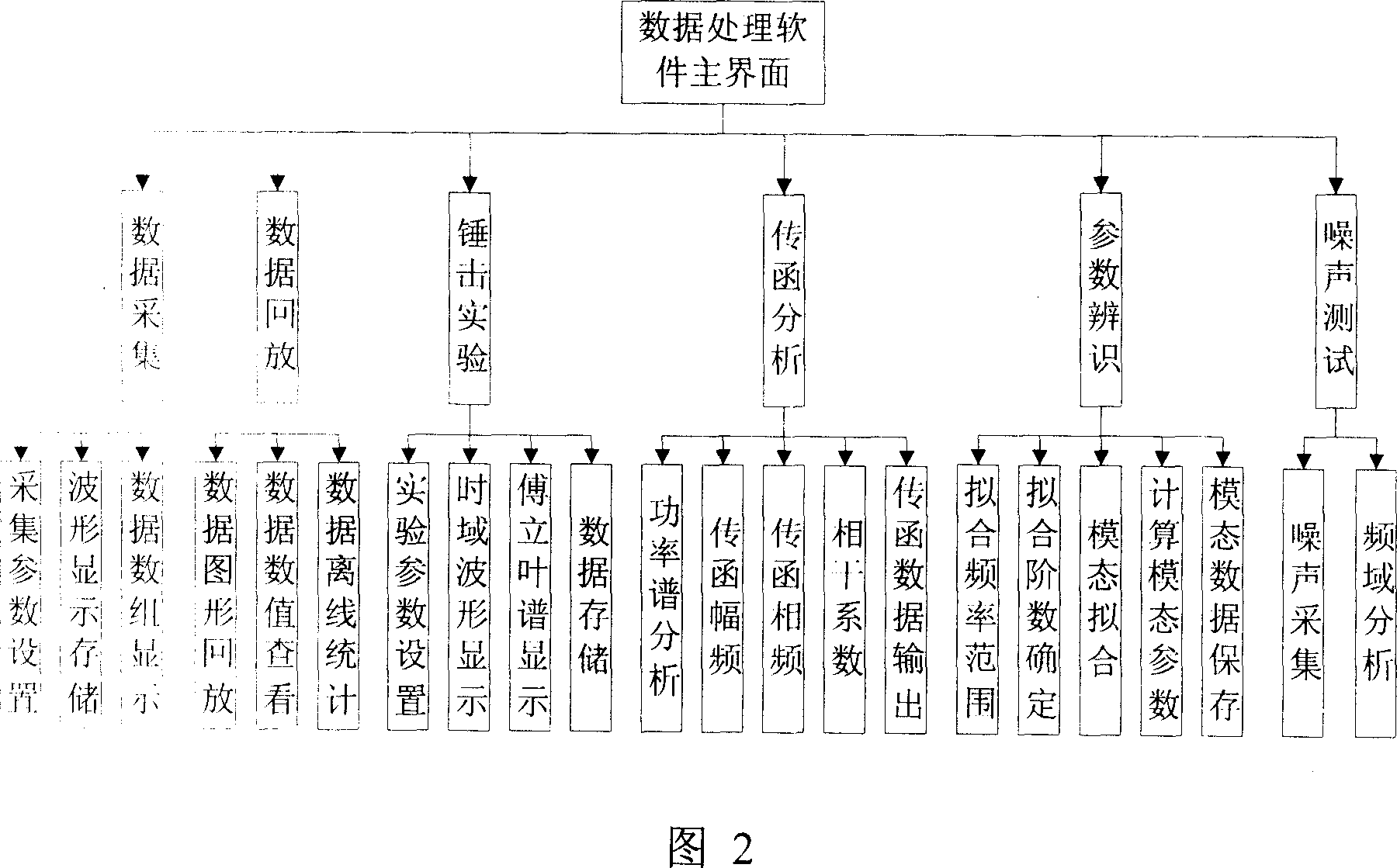

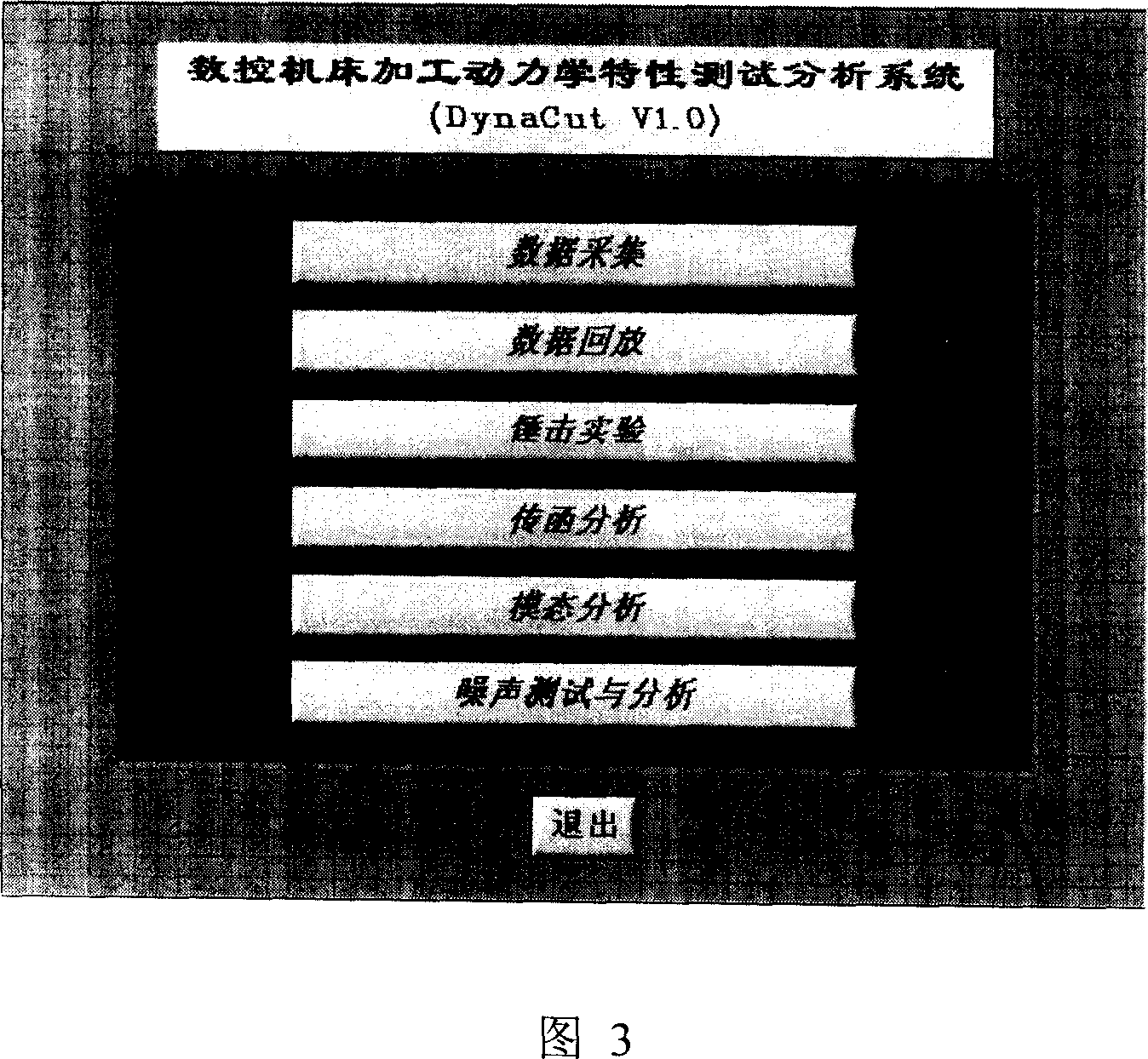

[0066] The present invention is a kind of numerically controlled machine tool machining dynamic characteristic test and analysis system, and the experimental test method is the single-point excitation single-point response method, please refer to shown in Figure 21, the accelerometer is installed on the cutter tip of the milling cutter, and the force hammer 2 is in the numerical control The other side of the machine tool tool 1 excites the CNC machine tool tool 1, and two charge signals are obtained from the hammer 2 and the accelerometer, and the charge amplifier 4 and the data collector 7 reach the memory of the computer 11, and the software reads the signal from the memory of the computer 11. Output and display the data, save it as a text file format, and perform FFT analysis, transfer letter analysis, and modal analysis on the measured data. The hardware and software cooperate to obtain the frequency response function (FRF) file and all modal parameters of "machine tool-too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com