Production of high-brightness light-emitting diodes chip

A light-emitting diode, high-brightness technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing yield, damage, cracking, etc., to improve the pass rate, avoid damage, and increase production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

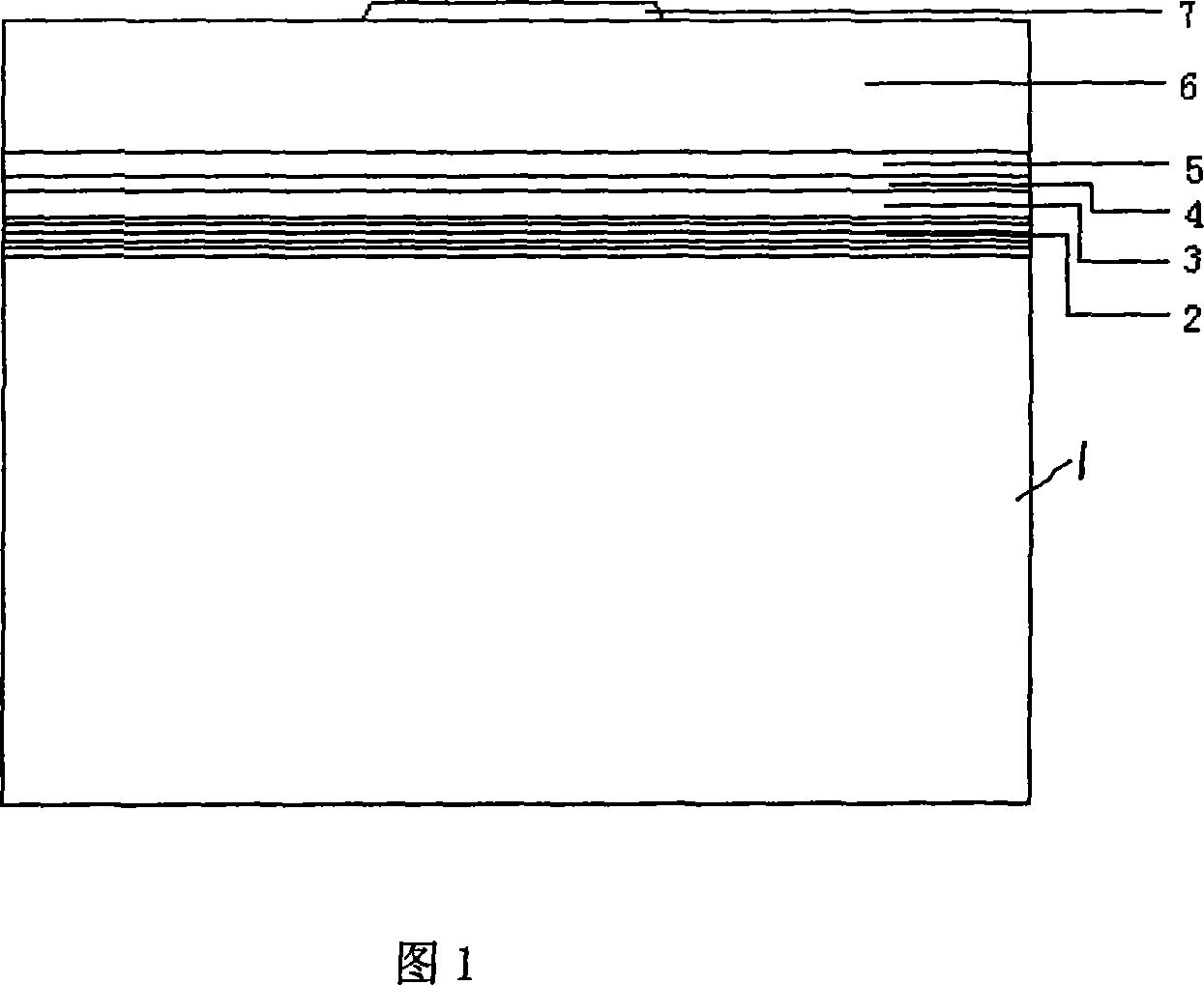

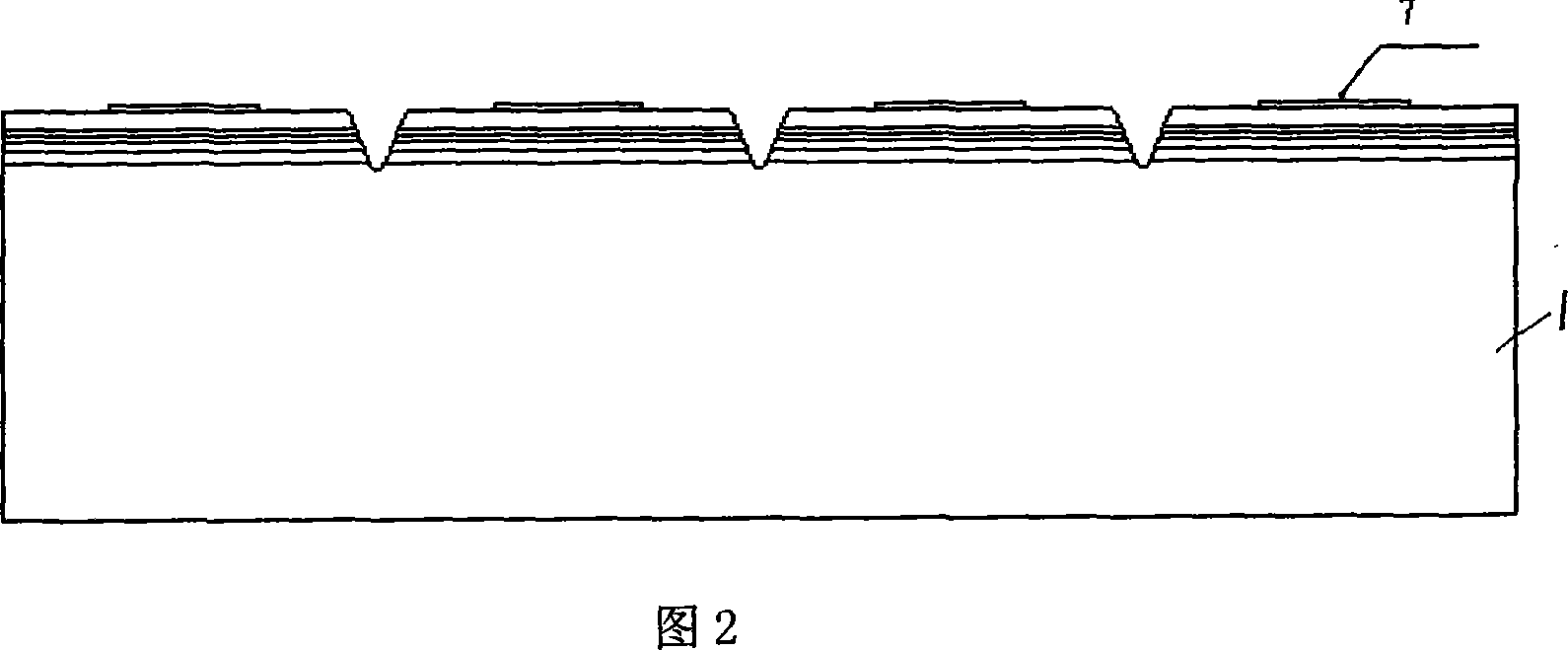

[0024] The invention uses the photoresist as the corrosion protection layer, and through the methods of selective exposure, development and chemical corrosion, completes the negative pole of the GaAs substrate and separates the positive pole of the light-emitting diode chip. Specifically, after the conventional LED process is done, the following steps are carried out before testing:

[0025] 1. Uniform glue: evenly coat positive photoresist on the surface of the LED epitaxial wafer. Carry out on the homogenizer, the speed of the homogenizer is 4000 rpm, and the time is 20 seconds.

[0026] 2. Baking: put the light-emitting diode epitaxial wafer coated with positive photoresist into an oven, and bake at a temperature of 100-150 degrees for 10-30 minutes.

[0027] 3. Exposure: exposure on a UV lithography machine, the mask pattern is shown in Figure 5, align with the original electrode pattern, and expose in the exposure area 8 with a width of 20 to 50 microns between each chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com