Method of preparing metalloporphyrin/silicon dioxide degradation agent

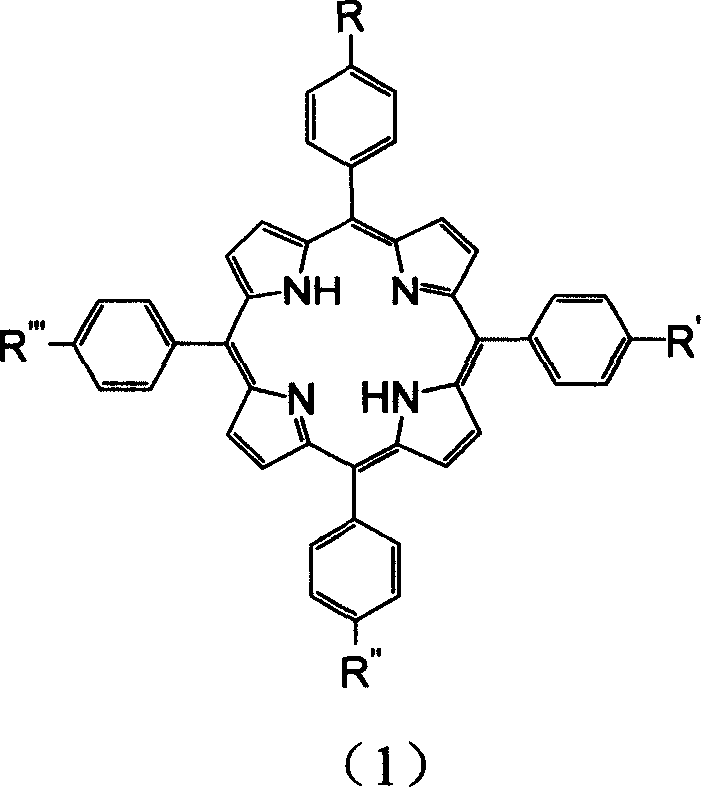

A metalloporphyrin and silicon dioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of reduced catalytic activity, easy oxidation and irreversible aggregation and other problems, to achieve the effect of easy reaction, wide practicability and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0018] Add 1g tetrahydroxycobalt porphyrin (CoTHPP) into a 2L flask, add 300mL THF, add 380mL TEOS and 130mL 4mol.L -1 Ammonia, fully stirred at room temperature for 8 hours, then put it into an oven, kept at 150-170°C for 2 hours, took out the reactant, and used CH 3 OH and THF washing, drying, prepared Tetrahydroxycobalt porphyrin / SiO 2 Degradant (CoTHPP / SiO 2 ), and its loading was calculated to be 1.21% by atomic absorption spectrometry.

preparation Embodiment 2

[0020] Add 1g of tetrahydroxyiron porphyrin (FeTHPP) into a 2L flask, add 300mL THF, add 380mL TEOS and 130mL 4mol.L -1 Ammonia, fully stirred at room temperature for 8 hours, then put it into an oven, kept at 150-170°C for 2 hours, took out the reactant, and used CH 3 OH and THF washing, drying, prepared Tetrahydroxyiron porphyrin / SiO 2 Degradant (FeTHPP / SiO 2 ), and its loading was calculated to be 1.4% by atomic absorption spectrometry.

preparation Embodiment 3

[0022] Add 1g tetrahydroxycopper porphyrin (CuHPP) into a 2L flask, add 300mL THF, add 380mL TEOS and 130mL 4mol.L -1 Ammonia, fully stirred at room temperature for 8 hours, then put it into an oven, kept at 150-170°C for 2 hours, took out the reactant, and used CH 3 OH and THF washing, drying, prepared tetrahydroxycopper porphyrin / SiO 2 Degradant (CuHPP / SiO 2 ), using atomic absorption spectrometry to calculate its load as 1.32%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com