Carbon nano tube with high water-solubility and preparation method thereof

A carbon nanotube, water-soluble technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve the effect of ensuring high purity, easy control of conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

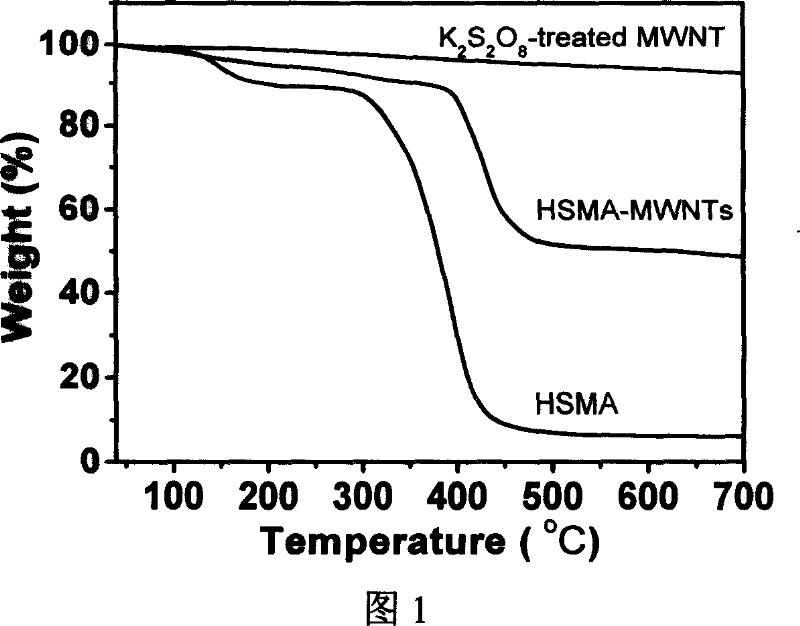

[0023] Add 100mg of multi-walled carbon nanotubes to 75ml containing 0.2mol / L K 2 S 2 o 8 After ultrasonic dispersion for 30 minutes, 12.5ml of 98% concentrated sulfuric acid was added, and stirred at 60°C for 24 hours. The treatment solution was centrifuged at 16000 RPM for 15 minutes, the precipitate was diluted with water, ultrasonically dispersed and then centrifuged, and the precipitate was repeatedly diluted, ultrasonically dispersed, and centrifuged until the solution was neutral. Finally, dry the black solid precipitate to obtain K 2 S 2 o 8 Processed multi-walled carbon nanotubes.

Embodiment 2

[0025] Add 100mg of single-walled carbon nanotubes to 75ml containing 0.2mol / L K 2 S 2 o 8 After ultrasonic dispersion for 30 minutes, 12.5ml of 98% concentrated sulfuric acid was added, and stirred at 60°C for 24 hours. The treatment solution was centrifuged at 16000RPM for 15 minutes, the precipitate was diluted with water, ultrasonically dispersed, and then centrifuged. Repeatedly diluted the precipitate, ultrasonically dispersed, and centrifuged until the solution was neutral. Finally, dry the black solid precipitate to obtain K 2 S 2 o 8 processed single-walled carbon nanotubes.

Embodiment 3

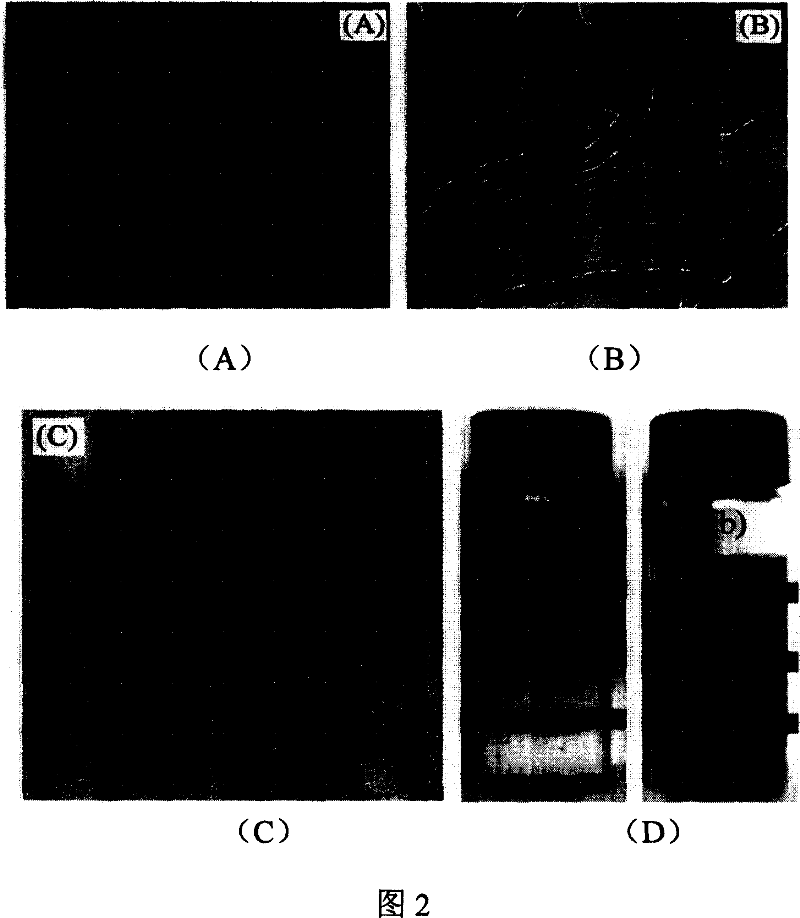

[0027] Take 50mg K 2 S 2 o 8 The treated multi-walled carbon nanotubes were added to 50 ml of 0.1 wt.% aqueous solution of hydrolyzed styrene-maleic anhydride copolymer (Mn=23360), and then the mixed solution was ultrasonically dispersed for 2 hours.

[0028] The obtained ultrasonic dispersion was centrifuged at a speed of 16000 RPM for 15 minutes. The supernatant was discarded, and the precipitate obtained by centrifugation was added to 50 ml of a 0.1 wt.% hydrolyzed styrene-maleic anhydride copolymer aqueous solution, and then the mixed solution was ultrasonically dispersed for 60 minutes. The obtained ultrasonic dispersion liquid was centrifuged at a speed of 16000 RPM for 15 minutes, and the supernatant liquid was collected. The resulting precipitate was added to 50ml of 0.1wt.% aqueous solution of hydrolyzed styrene-maleic anhydride copolymer and repeated ultrasonic dispersion for 60 minutes, followed by centrifugation at 16,000 RPM for 15 minutes, and repeated 9 cycle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com