Heat-resistant bismaleimide/epoxy resin and preparation method thereof

An epoxy resin and epoxy resin curing technology, applied in the field of heat-resistant double horse/epoxy resin, can solve the problems of high brittleness, high cross-linking density, poor workmanship, etc., achieve low cost, simple operation, and improve cohesion intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

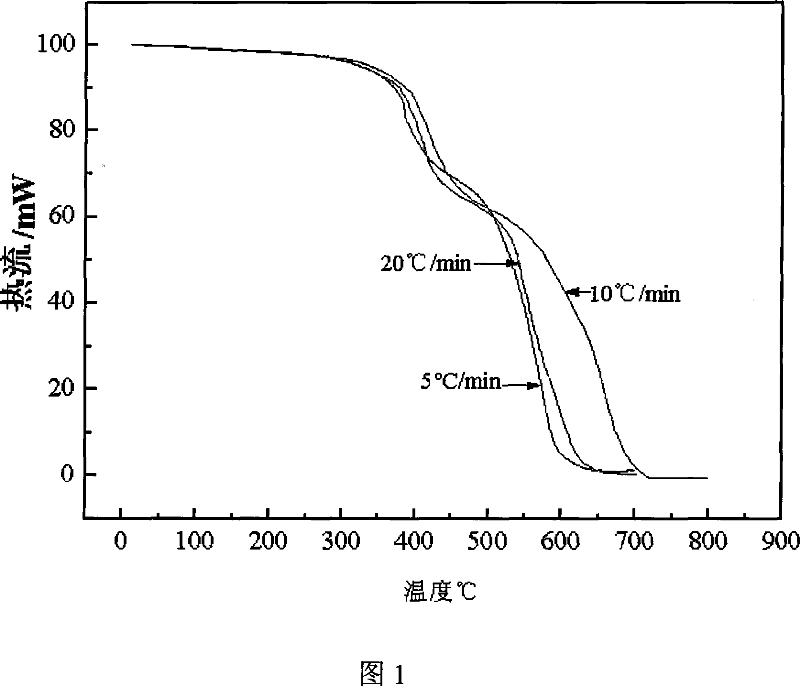

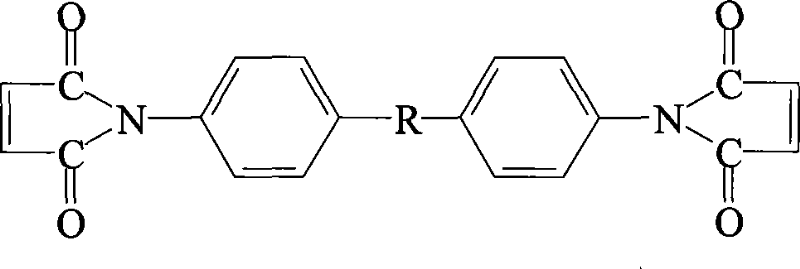

[0028] The diphenylmethane bismaleimide industrial product in Example 1, impurity: ≤0.1%, melting point: 152-160 ° C, produced by Honghu Shuangma Resin Factory in Hubei Province, diaminodiphenyl sulfone is chemically pure, Purity ≥ 98.0%, melting point 189.0-191.0, produced by Sinopharm Chemical Reagent Co., Ltd.; diphenyl ether bismaleimide in Example 2 was synthesized in a laboratory, and the reference for the synthesis method: D.O.Humme, K.U.Heinen, H. Stenzenberger, and H.Siesler.Appl.Polym.Sci.18, 2015(1974); diaminodiphenylmethane is chemically pure, with a purity ≥ 98.0%, and a melting point of 120.0-121.0, produced by Sinopharm Chemical Reagent Co., Ltd.; phenolic type Epoxy resin F-51 is an industrial product with an epoxy value of 0.51, and N,N'-dimethylformamide is analytically pure with a purity ≥ 99.0%, produced by Shanghai Reagent No. 1 Factory.

[0029] Example 1

[0030] (1) Preparation of bismaleimide curing agent for chain extension o...

Embodiment 2

[0039] (1) Preparation of bismaleimide curing agent for chain extension of diaminodiphenylmethane

[0040] Add 0.02mol of diphenyl ether bismaleimide and 0.005mol of diaminodiphenylmethane (the molar ratio is 4:1) into the reactor with stirrer, thermometer and condensing device, stir Heat until the system melts, react at a temperature of 120°C±10°C for 15 minutes, and finally add 20ml of solvent N,N'-dimethylformamide to obtain reddish-brown bismaleimide with chain extension of diaminodiphenylmethane Hardener.

[0041] (2) Preparation of epoxy resin containing bismaleimide

[0042] Under heating and stirring, add 5 grams of prepolymerized curing agent and 7 grams of F-51 epoxy resin in step (1) into the reactor with stirrer, thermometer and condensing device, at a temperature of 160 ° C ± 10 ° C Next, stir the reaction for 50 minutes. After the temperature of the above mixture was lowered to room temperature, a brown solid bis-hormone / epoxy resin was obtained.

[0043] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com