Pigment preparations based on PY 155

A technology of pigment preparation and pigment dispersant, which is applied in the direction of pigment slurry, organic dye, ink, etc., and can solve the problems of no application technical performance, agglomeration, poor crystal quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

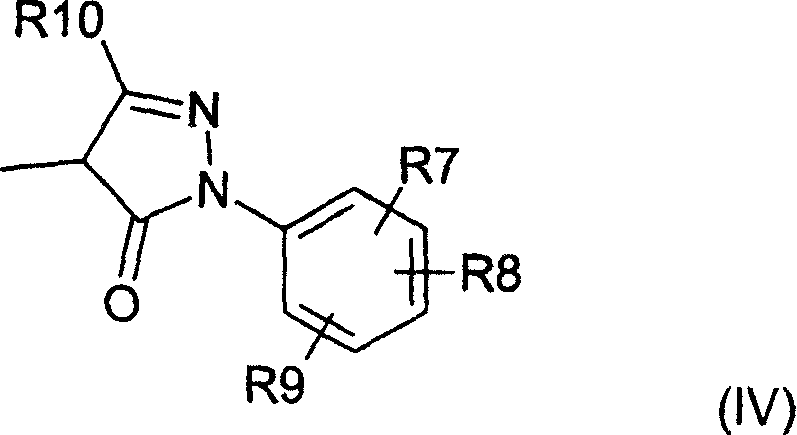

[0073] According to GB-A-2 239 254, crude pigments of formula (I) are prepared by coupling diazotized dimethyl 2-aminoterephthalate with bis(acetoacetamido)benzene, but without subsequent heated in dimethylformamide.

[0074] With 1350 parts of water, 6.25 parts of styrene-maleic anhydride copolymer (SMA3000HNa Sartomer) and 6.25 parts of the pigment dispersant of formula (VII) are adjusted into slurry. The mixture was stirred for several hours. Then, 38.4 parts of sodium hydroxide and 250 parts of crude pigment were added, and the mixture was stirred until a uniform slurry was formed. Subsequently, 150 parts of o-dichlorobenzene were added and the slurry was stirred under reflux for 1 hour. Maintain the pH above 10.5 throughout the finishing process. Then, the solvent was removed from the mixture by steam distillation. It was filtered, and the filter cake was washed with deionized water to neutral pH, dried, and ground on a rotor mill.

Embodiment 2

[0076] Repeat Example 1, the difference is to use 2.5 parts of the pigment dispersant of formula (VII), do not use SMA3000HNa (Sartomer).

Embodiment 3

[0078] Example 2 was repeated except that 12.5 parts of the pigment dispersant of formula (VII) was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com