Fibre-optical freezing sensor

An ice sensor and optical fiber technology, applied in the field of photoelectric sensors, can solve the problems of complex signal processing, large volume and weight, poor reliability, etc., and achieve the effects of simple signal processing, good electromagnetic compatibility, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

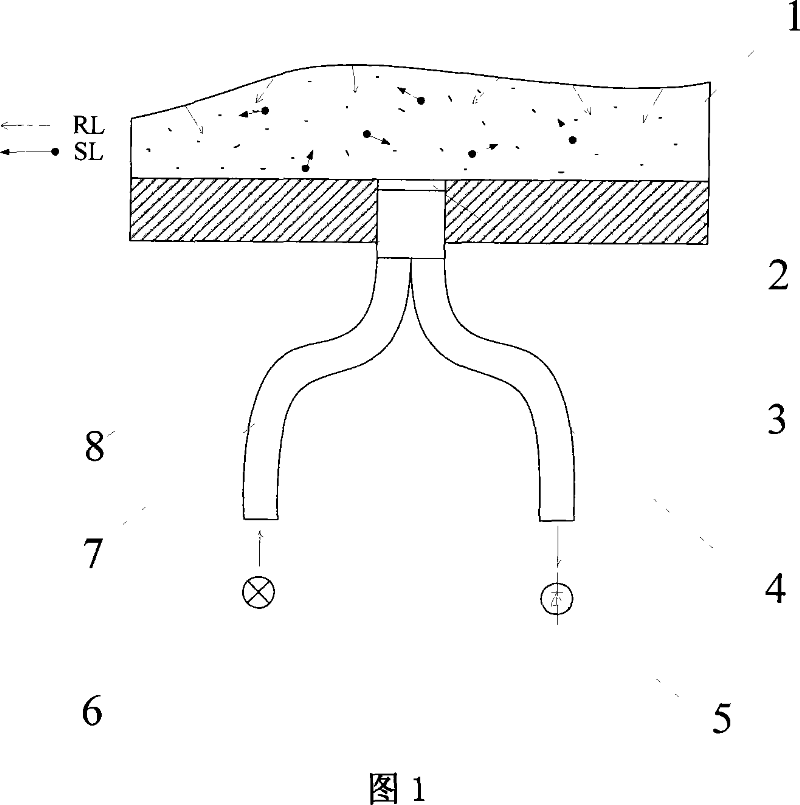

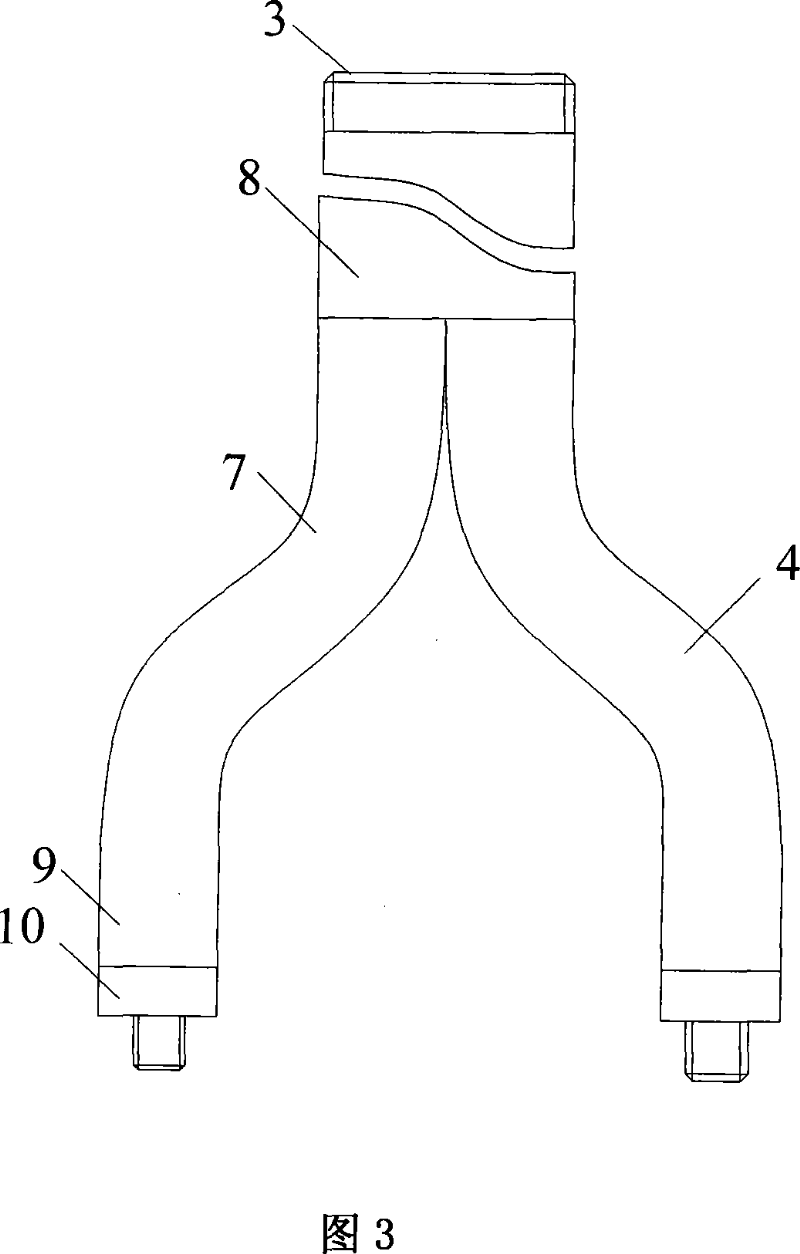

[0015] The present invention will now be described in detail in conjunction with FIGS. 1 to 4 .

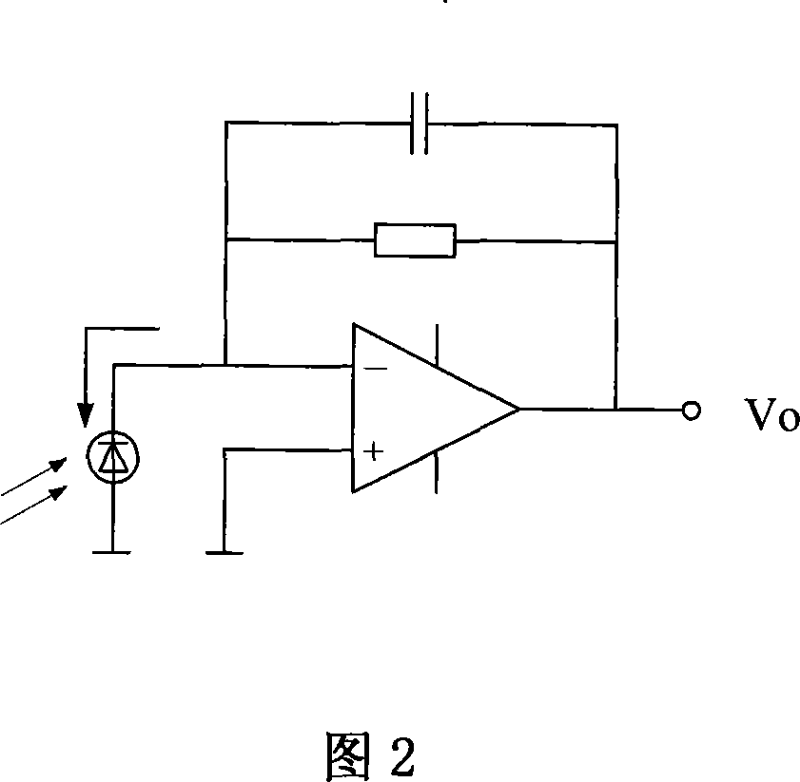

[0016] In Fig. 1, the ends of the transmitting optical fiber bundle 7 and the receiving optical fiber bundle 4 are merged into a concentrated optical fiber bundle 8, and its end face constitutes the end face 3 of the probe head, and its shape is a metal thread, which is convenient for screwing into the surface 2 of the measured object to achieve flushness installation purpose. The working wavelength of the light emitting device 6 in the transmitting circuit is near infrared, so as to eliminate the interference of the visible light in the background light to the detection circuit. When there is no icing on the surface 2 of the measured object, the emitted light from the light-emitting device 6 is transmitted along the emitting fiber bundle 7 and the concentrated fiber bundle 8 and enters the air through the end face 3 of the probe head, and the photodiode 5 cannot detect any emitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com