Process for preparing Lithium ionic cell electrode slurry using ultrasonic-mechanical raking combination method

A lithium-ion battery, mechanical stirring technology, applied in the direction of electrode manufacturing, etc., can solve the problems of battery cycle life reduction, electrode piece cracking, unsatisfactory effect, etc., to achieve battery internal resistance reduction, increase utilization rate, and improve high-power output characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Preparation process of positive electrode slurry for lithium ion battery

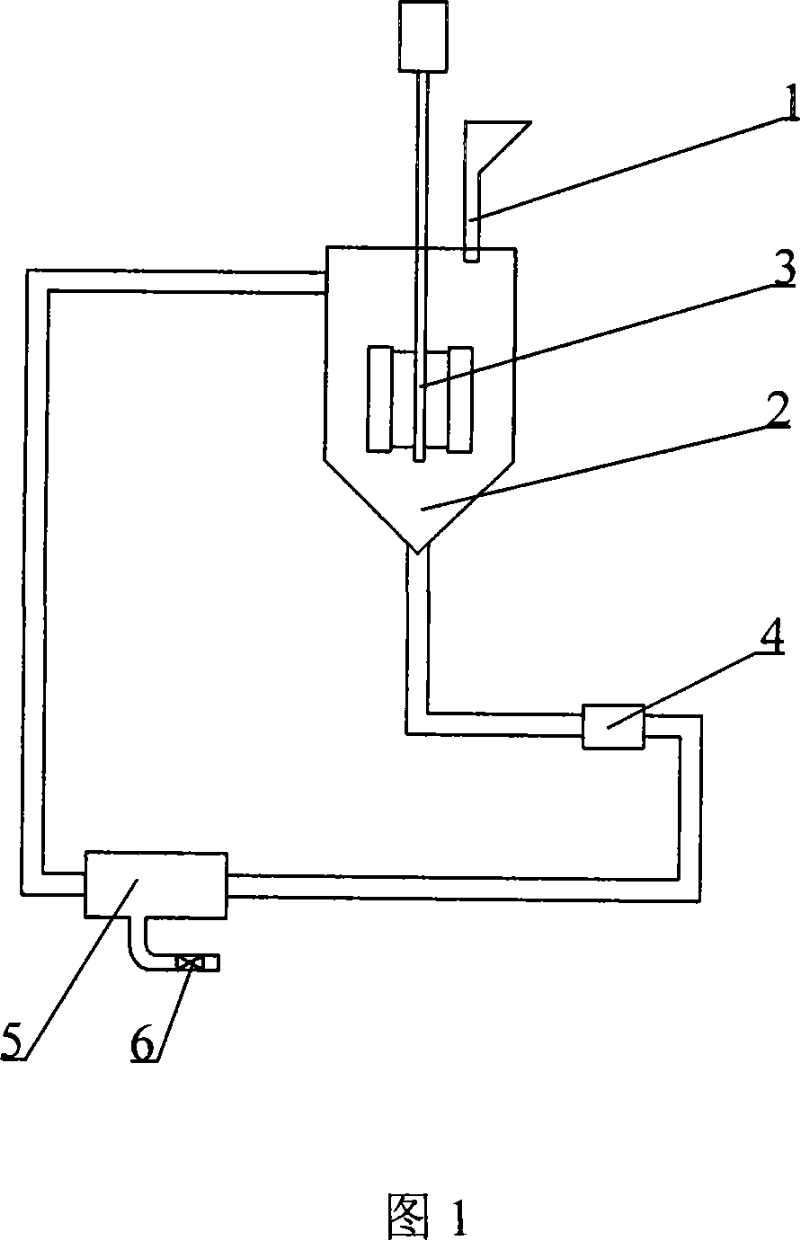

[0016] As shown in Figure 1, add 100 kg of n-methylpyrrolidone and 3 kg of polyvinylidene fluoride into the barrel 2 from the feeding port 1, turn on the mechanical stirring motor 3, adjust the stirring speed to 300 rpm, and stir until polyvinylidene fluoride After the ethylene difluoride was completely dissolved, carbon black was added into material tank 2 and stirred for 1 hour. Then use the liquid pump 4 to send the above-mentioned mixed solution into the hydrodynamic ultrasonic generator 5 and carry out ultrasonic treatment. The outlet pressure of the liquid pump is 0.5MPa, and the liquid flow rate is 15m 3 , The ultrasonic sound intensity is 180dB. The ultrasonically treated mixed solution is sent back to the barrel 2 to continue stirring, so that the mixed solution circulates for 1.5 hours between the loops formed by the ultrasonic generator 5 and the barrel 2 . Finally, add LiM...

Embodiment 2

[0017] Example 2 Dispersion of conductive agent in electrode slurry

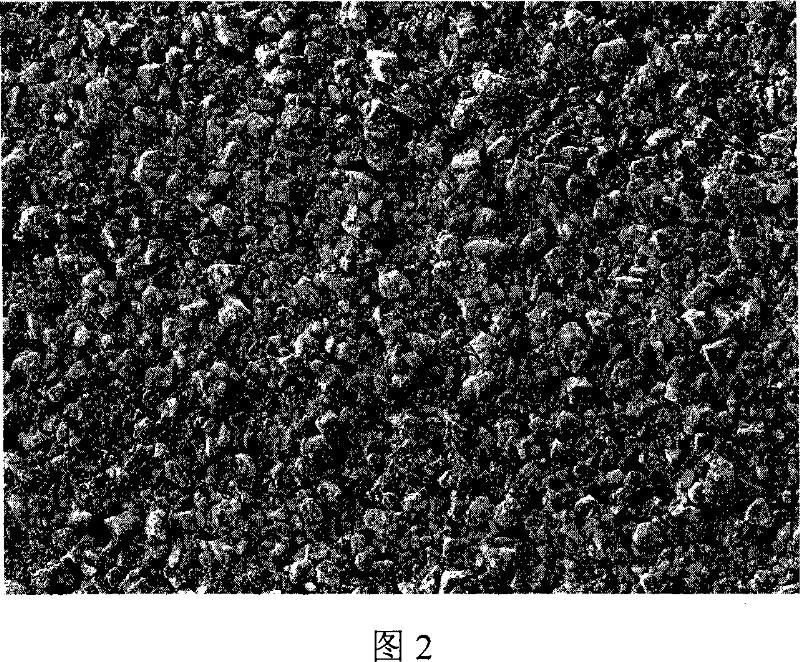

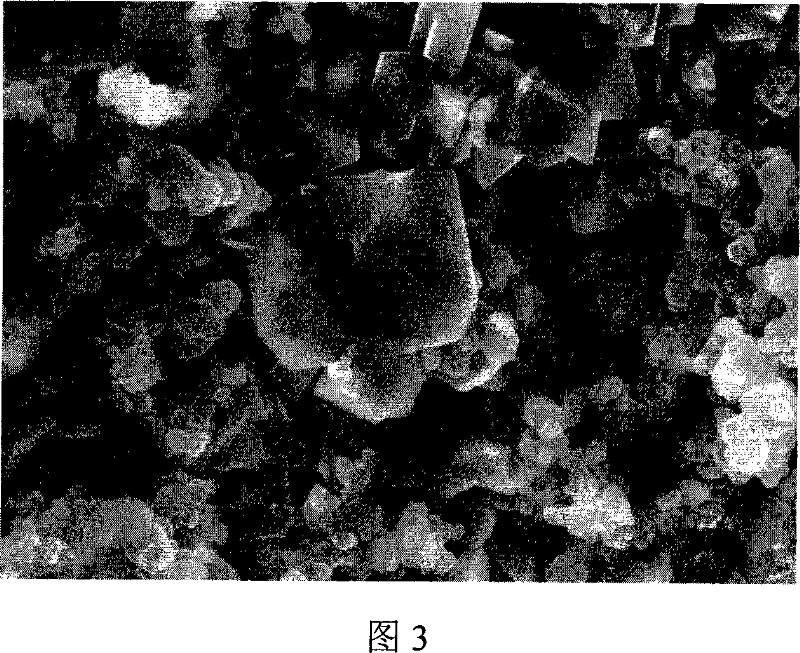

[0018] The electrode slurry prepared in Example 1 was coated on aluminum foil, and the surface morphology of the prepared coating was studied by scanning electron microscope (SEM). Figure 2 shows the SEM image at 200 times magnification, and Figure 3 shows the SEM image at 50,000 times magnification. It can be seen from Figure 2 that in the electrode active material LiMn 2 o 4 The surface is covered with a uniform layer of conductive material carbon black, indicating that carbon black and LiMn 2 o 4 Mix well. In Fig. 3, the large particles with regular shape are the electrode active material LiMn 2 o 4 , the small particles are carbon black, as can be clearly seen from the figure, each carbon black particle is separated, indicating that the carbon black does not agglomerate, which proves that the present invention can realize the high dispersion of the conductive agent in the electrode slurry .

Embodiment 3

[0019] Example 3 Preparation process of negative electrode slurry for lithium-ion batteries

[0020] Repeat the steps of Example 1, the difference is that the positive electrode material LiMn 2 o 4 Replaced with negative electrode material graphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com