Hyperfiltration sea-water distillatory with energy recovery

A technology of energy recovery and reverse osmosis, applied in the direction of osmosis/dialysis water/sewage treatment, reverse osmosis, general water supply saving, etc., can solve the problems of long start-up time, difficult parameter coupling adjustment, etc., achieve low cost and facilitate popularization and use , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

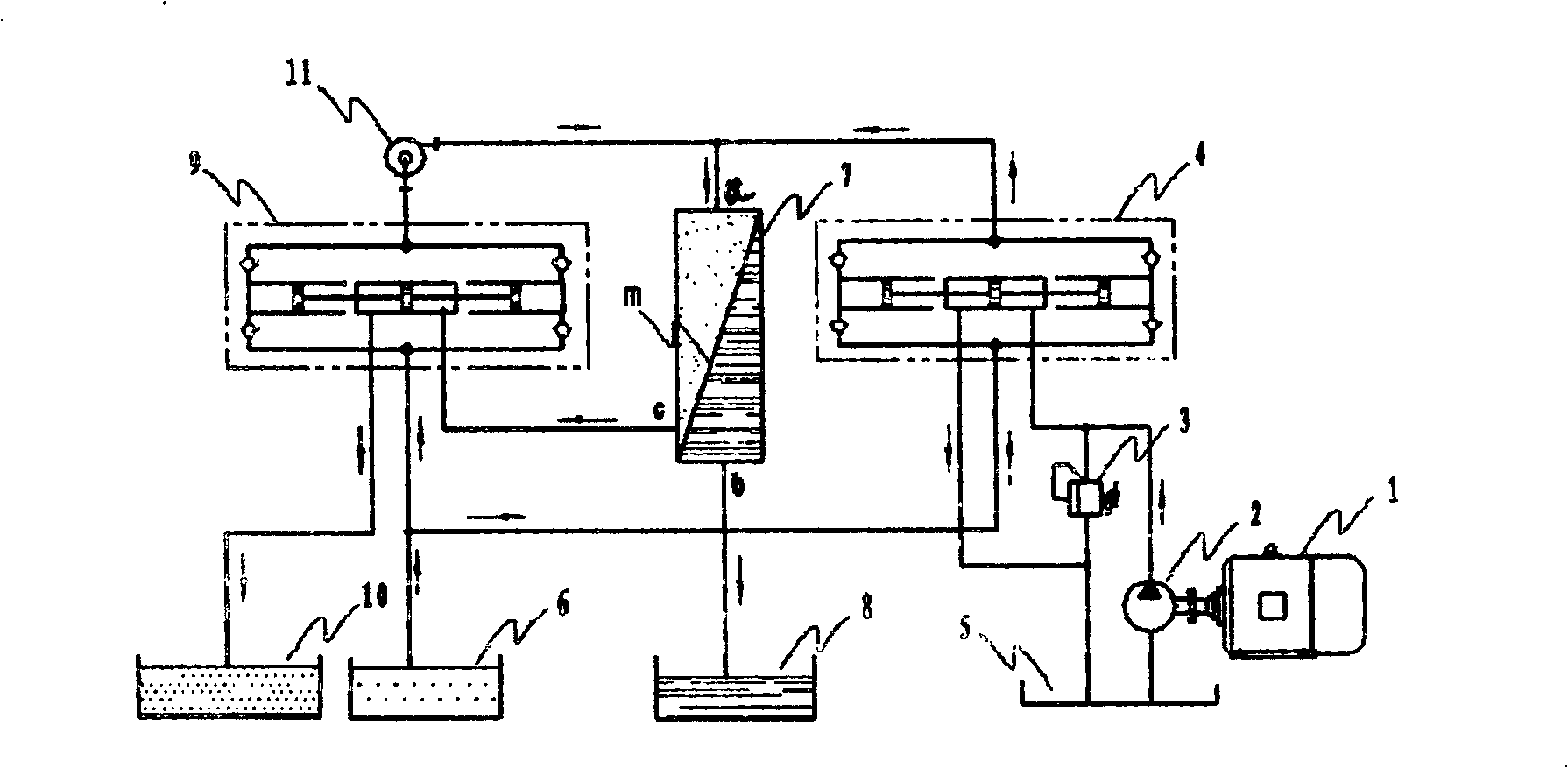

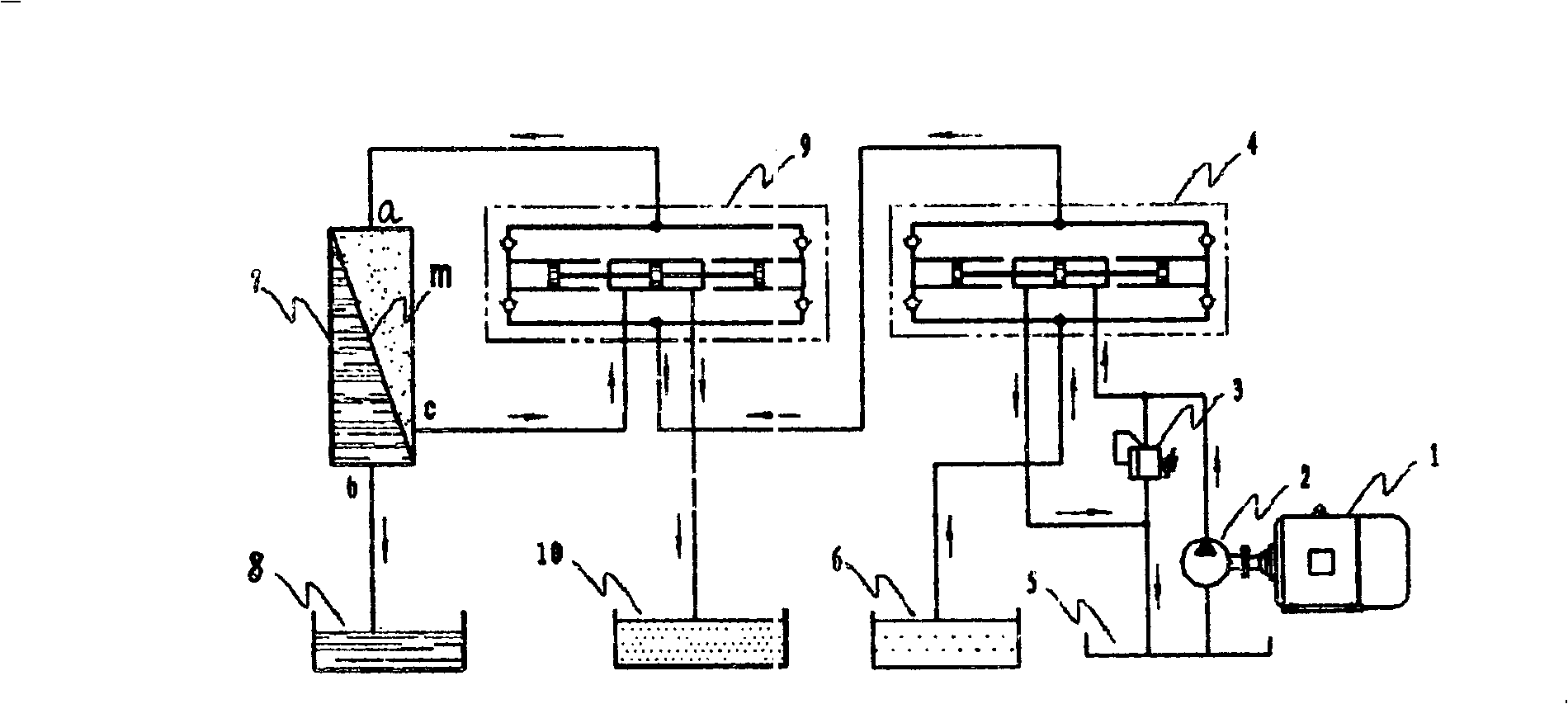

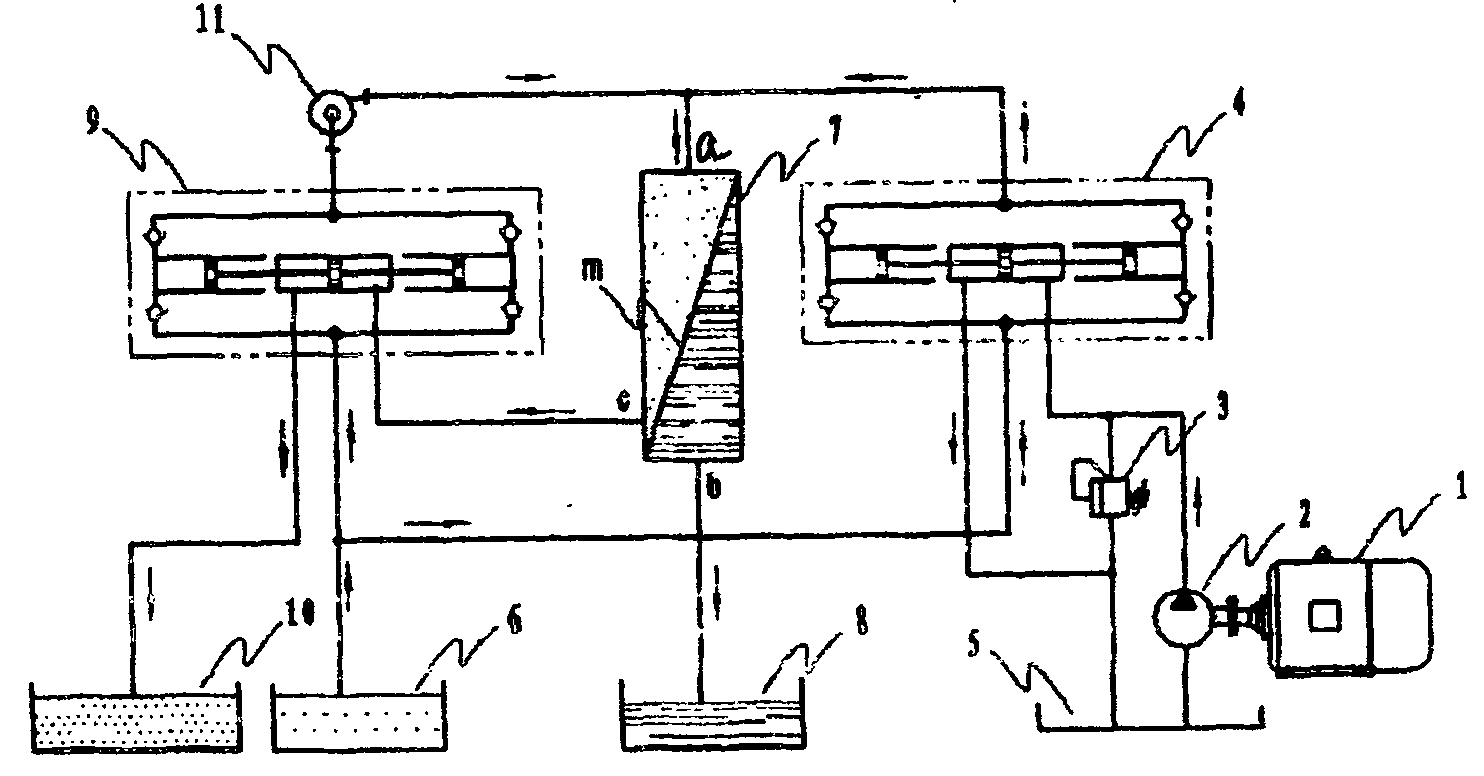

[0011] Such as figure 1 As shown: the motor 1 drives the hydraulic oil pump 2, and the oil pump 2 injects the hydraulic oil in the oil tank 5 into the main water pump connected in series to the front end of the desalination membrane device, that is, the hydraulic cylinder of the hydraulic double-cylinder single-acting pump 4, and a relief valve 3 on the way In parallel connection, when the power fluid is injected, it will automatically reciprocate, so that the water pump will inject the raw water in the raw water tank 6 to the water inlet a of the desalination membrane device 7, and the hydraulic oil will drive the high-pressure water pump, and then flow back to the oil tank 5 for endless circulation; the desalination membrane The raw water in device 7 is filtered by membrane m under appropriate high pressure, and the separated fresh water flows from outlet b to fresh water pool 8, and the salt content of seawater in front of the membrane rises to become concentrated brine, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com