Calcium-enriched alta-mud for railway and high road foundation treatment

A technology of calcium bentonite and bentonite, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effects of increasing elasticity, preventing roadbed settlement, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

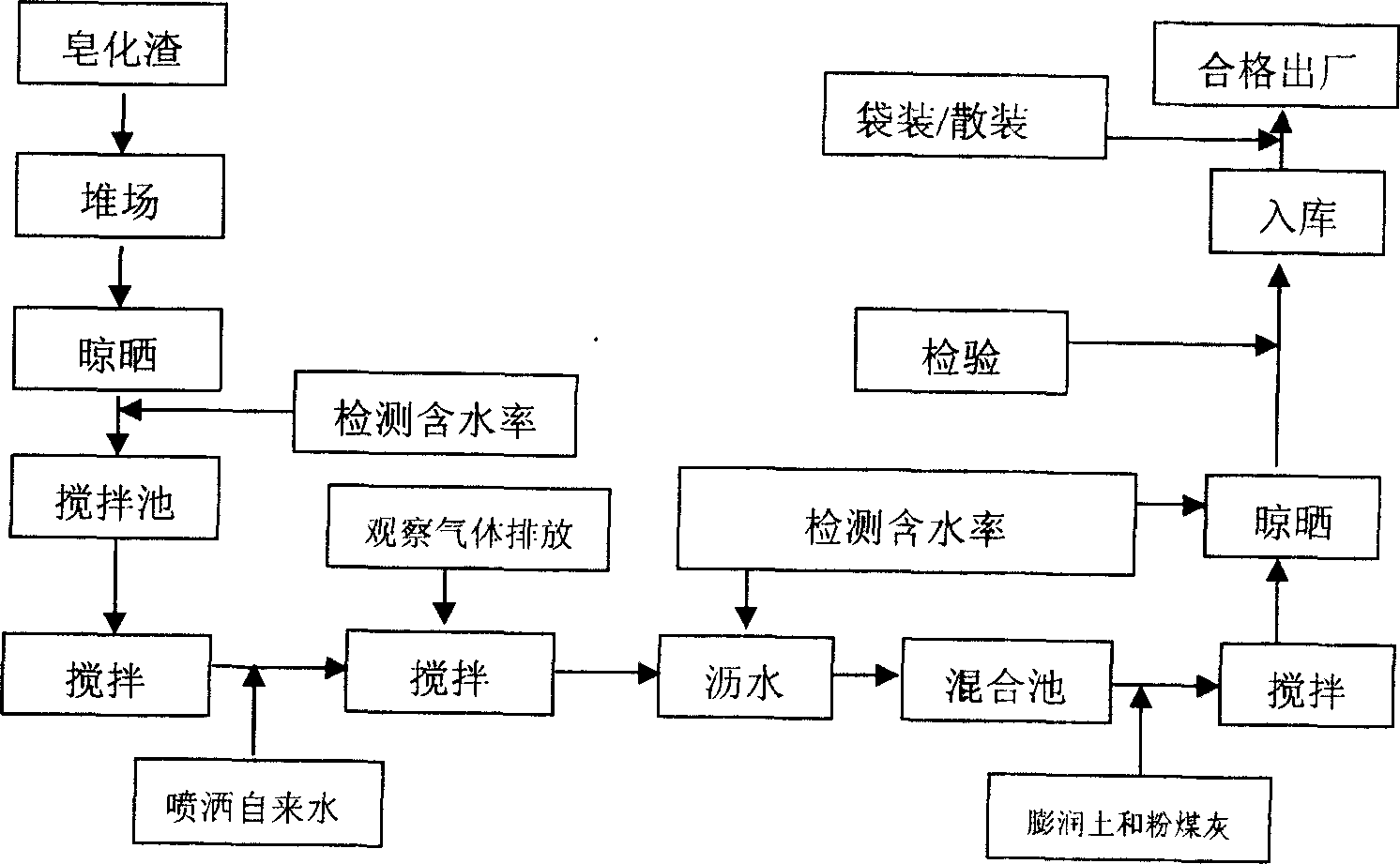

Method used

Image

Examples

Embodiment 1

[0013] A kind of calcium-increased bentonite used for the treatment of railway and highway subgrades, in terms of volume percentage m 3 The components are: saponified slag: bentonite: fly ash=1: 0.1: 0.1.

Embodiment 2

[0015] A kind of calcium-increasing bentonite used for railway and highway subgrade treatment, the composition according to its volume percentage m3 is: saponified slag: bentonite: fly ash=1: 0.1: 0.6.

Embodiment 3

[0017] A kind of calcium-increased bentonite used for the treatment of railway and highway subgrades, in terms of volume percentage m 3 The components are: saponified slag: bentonite: fly ash = 1:0.1:0.3

[0018] The preparation method of calcium-increasing bentonite:

[0019] 1. Feeding

[0020] Including drying, stirring, and transporting the saponification slag to the raw material yard. Take 750 cubic meters of saponification slag and put it into the drying yard, pile it up according to the ratio of length, width and height of 30:25:1, and stir it with a bamboo rake to accelerate the dehydration. After drying in the sun until the water content in the saponification slag is lower than 30%, put it into a stirring tank and stir until the particle diameter of the raw material block is less than 2 cm. Unqualified return to the drying link.

[0021] 2. Neutralization, washing and draining

[0022] It includes four steps of adding sulfuric acid, washing with water, draining, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com