Burner of possessing multiplepath entrances of solid fuel, and application

A solid fuel and burner technology, applied in the direction of granular/powder fuel gasification, etc., can solve the problems such as difficulty in accurate measurement of solid material conveying parameters, difficulty in strict control of gasification process conditions, uneven distribution of gas-solid two-phase flow, etc. , to avoid the difficulty of solid fuel flow rate measurement, good process effect, and improve the uniformity and flow stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

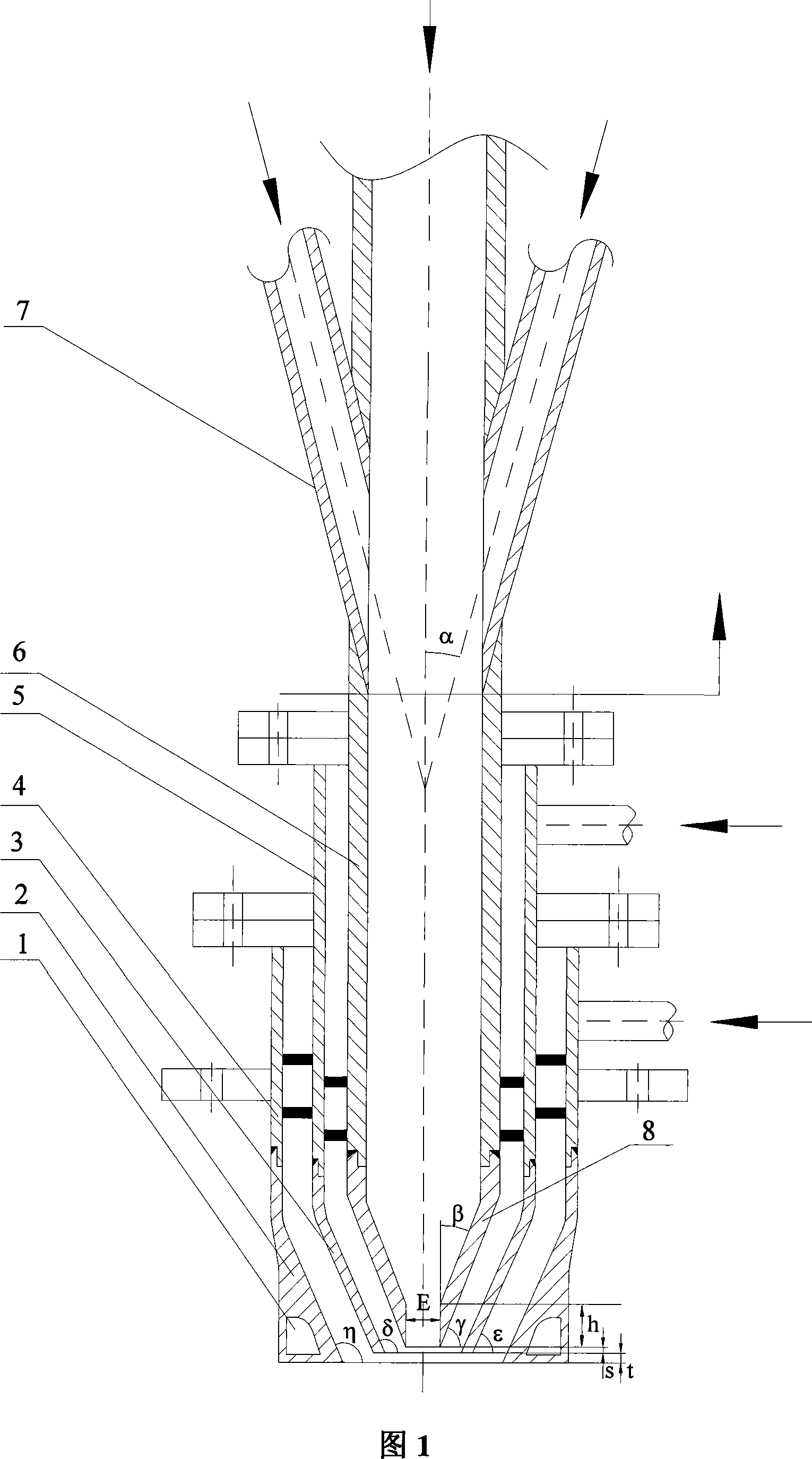

[0030] A burner with three solid fuel inlets as shown in Figure 1 is used to feed the entrained bed reactor, including two delivery branch pipes, and a central delivery pipe coaxial with the central conduit. The first communication method mentioned above is adopted for the connection between the two delivery branch pipes and the central catheter. The angle a formed by the branch pipe and the central catheter is 30°.

[0031] The inner contraction half angle β of the inner nozzle is 1°, the outer inclination γ is 70°, the inner contraction half angle δ of the middle ring nozzle is 20°, the outer inclination ε is 70°, and the inner contraction half angle η of the outer ring nozzle is 30°. The ratio of the nozzle diameter E of the inner nozzle to the straight section h of the nozzle is 1. The distance s between the nozzle end face of the inner nozzle and the middle ring nozzle is 0 mm, and the distance t between the nozzle end face of the middle ring nozzle 3 and the outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com