Processing method, processing device and saccharification method of extruded enzyme-added beer accessories

A technology for beer and auxiliary materials, which is applied in beer brewing, biochemical equipment and methods, and wort preparation, etc., can solve the problems of slow starch degradation, low starch utilization rate, incomplete degradation, etc., and achieves less saccharification time. , The effect of short saccharification time and fast filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation

[0025] Embodiments of the invention:

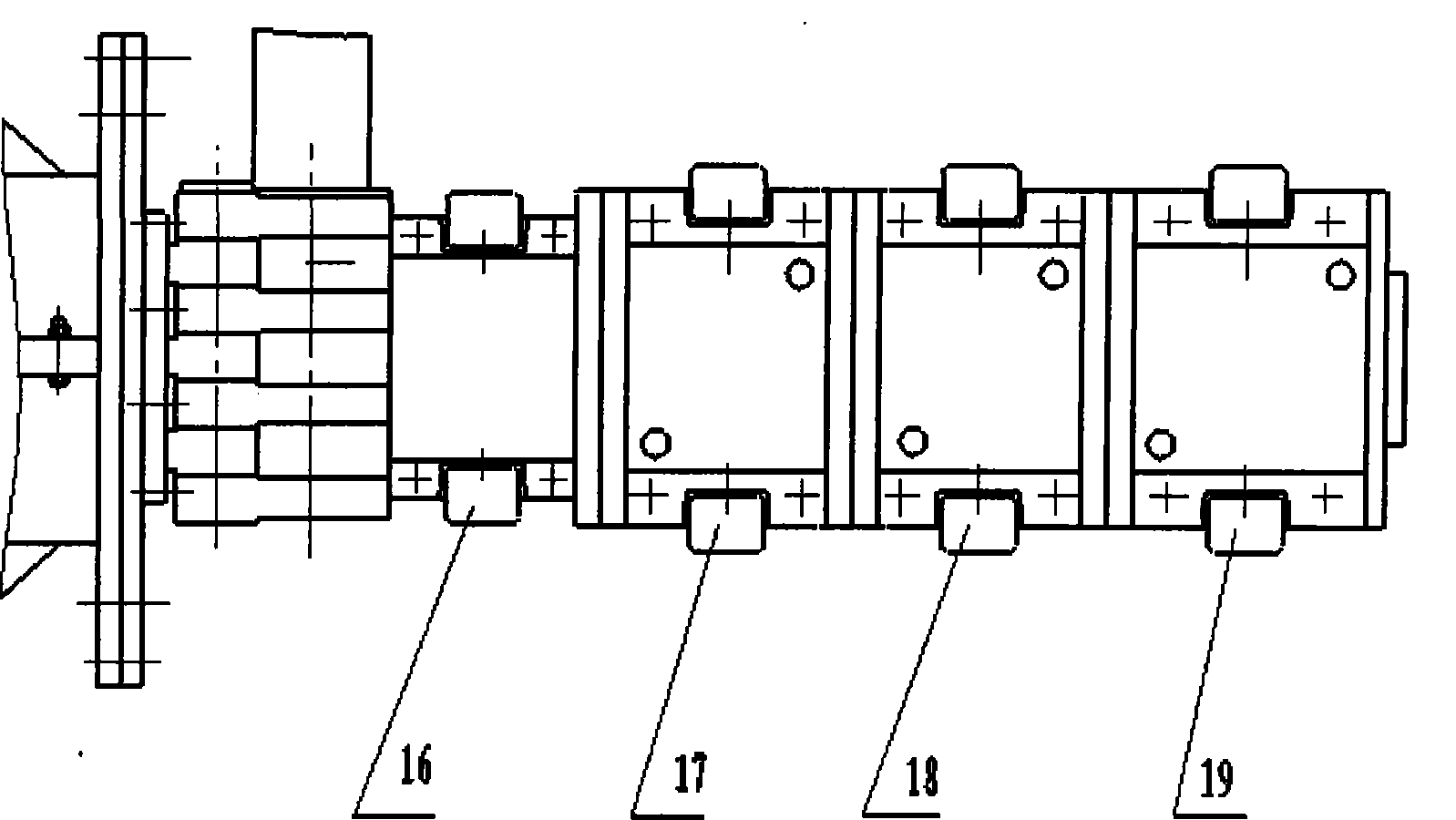

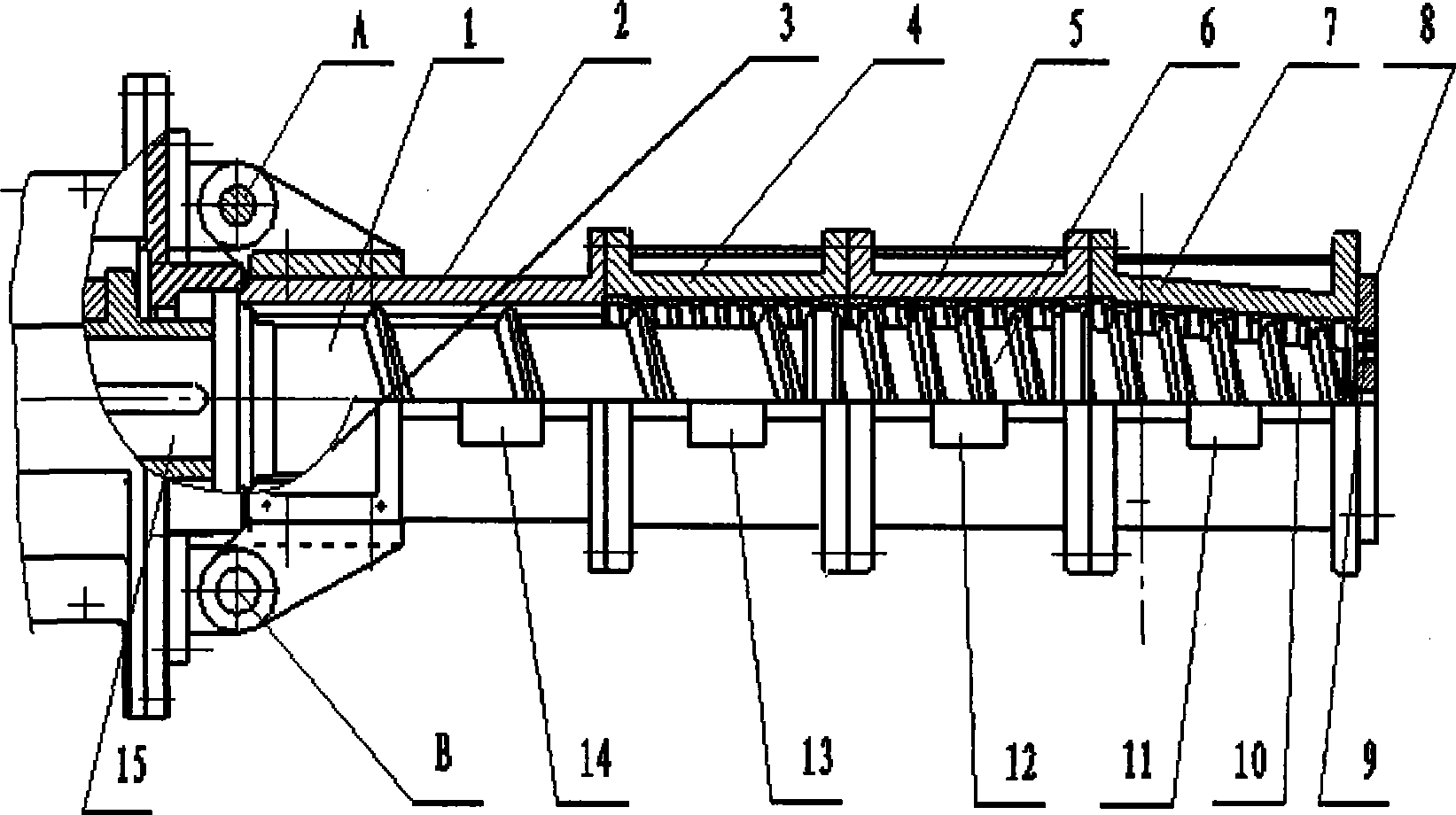

[0026] see figure 1 with figure 2 , The extrusion cooking device of the present invention is mainly composed of an axially split sleeve and a screw. The sleeve as a whole is composed of the first section of the sleeve 2, the second section of the sleeve 4, the third section of the sleeve 5 and the fourth section of the sleeve 7 in the axial split type. Each section of the sleeve is installed from the rear to the front. The thread on the inner surface of the open sleeve as a whole is a continuous helix, and the upper and lower parts of the above-mentioned sleeve are respectively fastened by fasteners 14, 16, 13, 17, and Part 12, fastener 18, fastener 11 and fastener 19 lock the upper and lower parts of the above-mentioned sections of sleeve. The first joint screw rod 1 , the second joint screw rod 6 and the third joint screw rod 10 are sleeved on the main shaft 15 , and the screw rods are installed fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com