Corrosion inhibitor for restraining metal corrosion, and preparation method

A metal corrosion and corrosion inhibitor technology, applied in the field of corrosion inhibitors, can solve the problems of complex product composition, high cost, and the film duration is not reported in detail, and achieves the effect of long film duration and high film formation strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

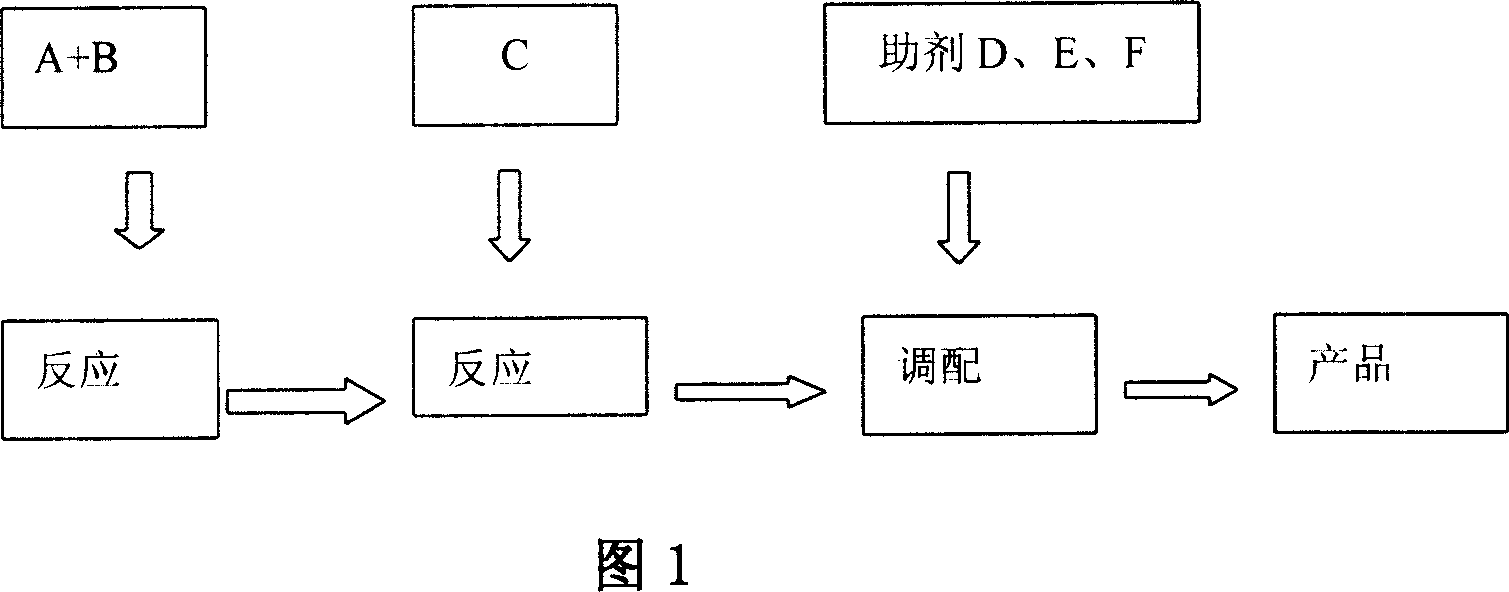

Method used

Image

Examples

Embodiment 1

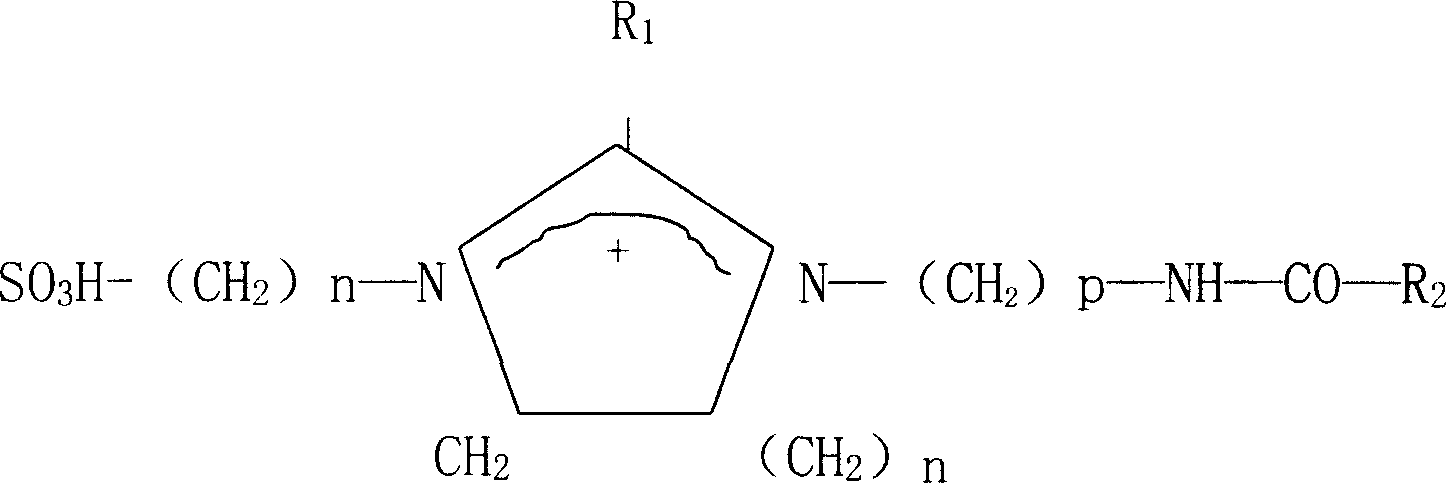

[0035] Preparation of imidazolines containing sulfur amides

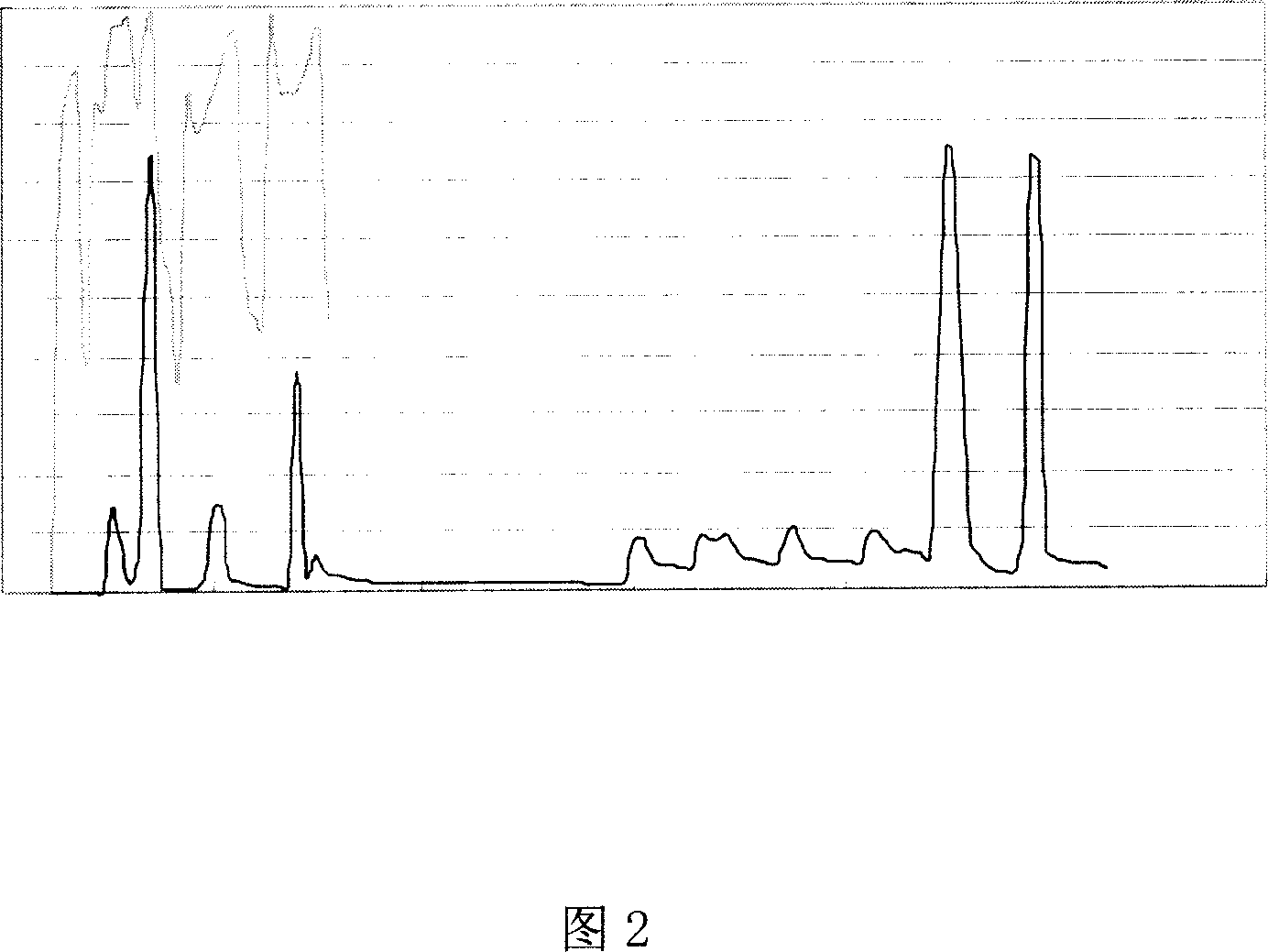

[0036]Use industrial oleic acid mixture (containing 40% oleic acid) and tetraethylenepentamine in a molar ratio of 2:2 to carry out the reaction in a four-necked flask or a chemical reactor (such as a Lab Max reactor). The flask is equipped with a stirrer, a liquid inlet funnel (the same as the inlet for nitrogen protection), a thermometer, and a branch pipe connecting the water separator and the condenser. Heat the industrial oleic acid to 60°C under the condition of nitrogen flow, then quickly add tetraethylenepentamine dropwise through the separatory funnel, and keep stirring the mixture, and raise the temperature to 170°C. At this time, about 1 mole of water was separated. Infrared spectrum shows that at this time at 1630cm -1 and 1550cm -1 There is an amide absorption peak at 3315cm -1 There is an N-H absorption peak in the free state. Then continue to heat up to 220°C and react for 3 hours. Formation of ...

Embodiment 2

[0048] First, industrial linolenic acid and diethylenetriamine are reacted in the reactor at a molar ratio of 2:1.2, and the linolenic acid is heated to 50°C under the condition of nitrogen, and then quickly added dropwise through a separatory funnel, and The mixture was kept stirring, and the temperature was raised to 160°C. At this time, about 1 mole of water was separated, and then the temperature was continued to rise to 225°C, and the reaction was carried out for 3 hours to generate amide imidazoline. Infrared spectrum shows that there is a characteristic absorption peak of imidazoline at 1610cm-1, the mass of the product is calculated according to the yield, and mercaptopropionic acid is added to the product with a molar ratio of 1:1.1, and the reaction is continued at 130°C for 4 Hours, sulfur-containing imidazoline derivatives are generated.

[0049] Compound the final reaction product with additives to form a corrosion inhibitor product. The formula is: 50% final pro...

Embodiment 3

[0060] First, sulfonated castor oil and tetraethylenepentamine are reacted in the reactor at a molar ratio of 2:2.5, and the linolenic acid is heated to 70°C under the condition of nitrogen, and then quickly added dropwise through a separatory funnel. And the mixture was kept stirring, and the temperature was raised to 175°C, at this time, about 1 mole of water was separated, and then the temperature was continued to rise to 225°C, and the reaction was carried out for 3 hours to generate sulfonated imidazoline. The infrared spectrum shows that there is a characteristic absorption peak of imidazoline at 1610cm-1, and the quality of the product is calculated according to the yield, and acrylic acid is added to the product with a molar ratio of 1:1.2, and the reaction is continued at 125°C for 4 hours. Generate sulfur-containing imidazoline derivatives.

[0061] Compound the final reaction product with additives to form a corrosion inhibitor product. The formula is: 45% final pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com