Baffle type column tray

A baffle-type tray technology, applied in the field of baffle-type trays, can solve the problems of low gas-liquid mass transfer efficiency, small processing capacity, complex structure, etc., and achieve simple structure, less mist entrainment, and liquid distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

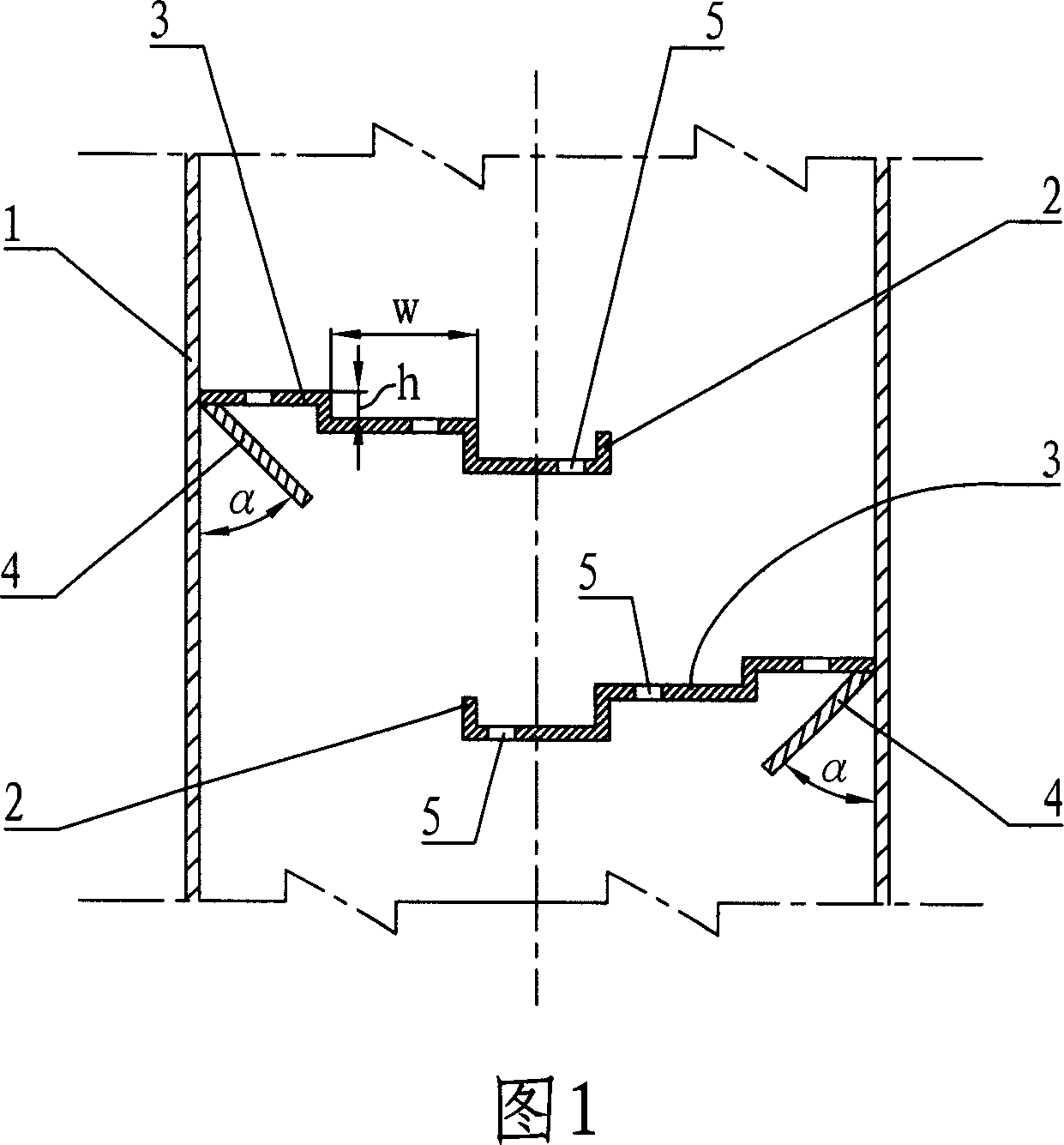

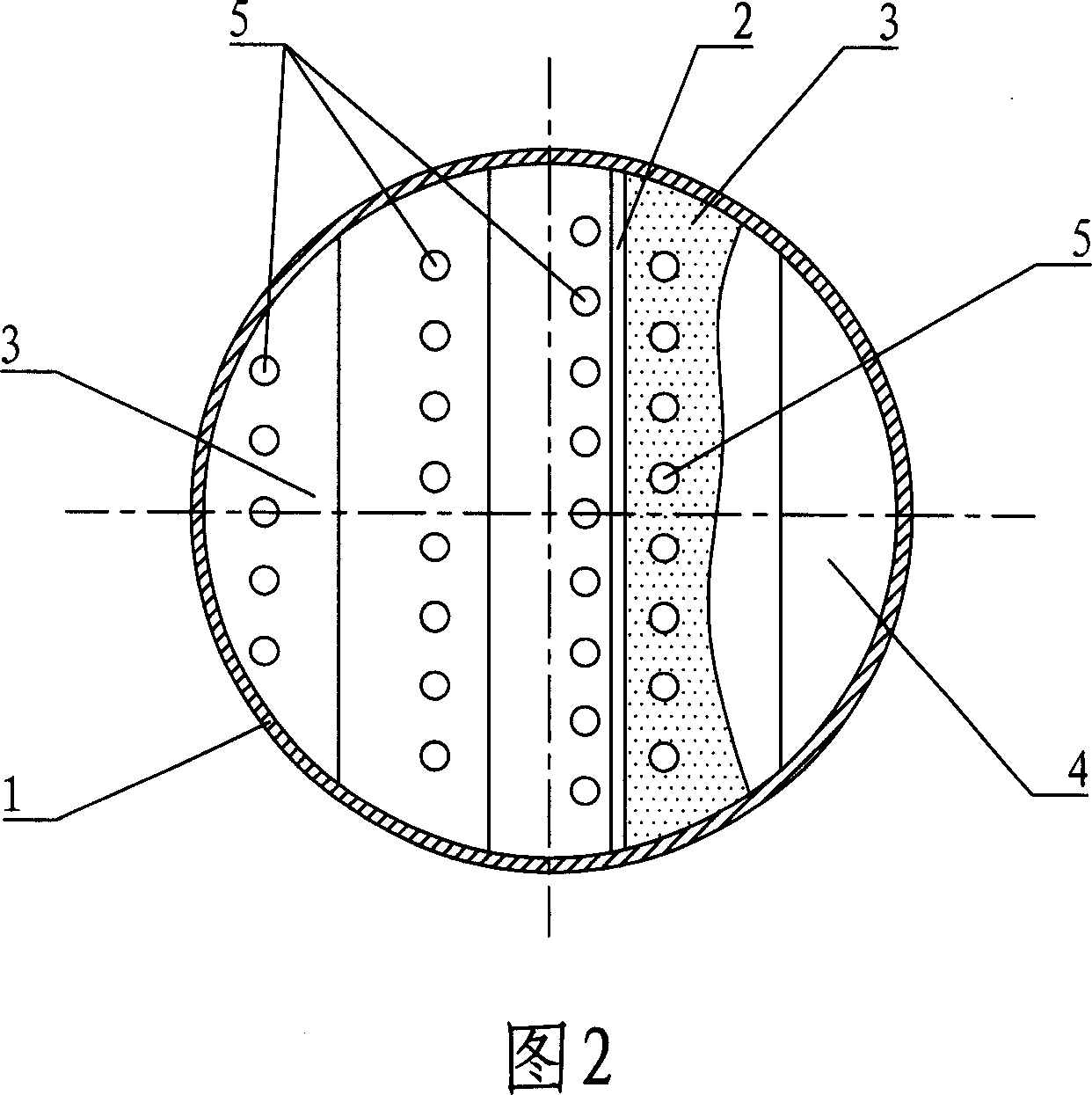

Embodiment 1

[0022] The test was carried out in an experimental tower with an inner diameter of φ600mm. 3 layers of baffle plate trays of the present invention are installed in the experimental tower, and the tray spacing is 600mm. The tray of each tray is composed of 3 steps, the height h of each step is 50mm, and the width w is 100mm. The thickness of the trays was 4 mm. The overflow weir on the lowest step tray is a flat weir with a height of 40mm. Circular sieve holes are evenly opened on the tray plate of each step, the diameter of the sieve holes is φ8mm, and the opening ratio is 15.8%. The deflector is a solid plate with a thickness of 4 mm and an angle α with the tower wall of 30 degrees. The area of the deflector is 1 / 4 of the cross-sectional area of the tower (experimental tower).

[0023] The test medium is air-water, and the hydraulic test is carried out at normal temperature (15-28°C). The strength of the liquid flow is 60m 3 / (m h), the superficial gas velocity is 0....

Embodiment 2

[0028] The test was carried out according to the experimental device and conditions of Example 1; the difference was that the angle α between the deflector and the tower wall was 45 degrees, and the superficial gas velocity was 1.7m / s. The test results are shown in Table 2.

Embodiment 3

[0032] The test was carried out according to the experimental device and conditions of Example 1; the difference was that the angle α between the deflector and the tower wall was 60 degrees, and the superficial gas velocity was 2.6m / s. The test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com