Composite absorbing material

A composite adsorption material and adsorption material technology, which are applied in the field of composite adsorption materials for the treatment of oily wastewater and wastewater containing refractory organic pollutants, can solve the problems of reduced adsorption capacity of activated carbon, easy blocking of activated carbon, blocking in pores, etc., and achieve adsorption Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

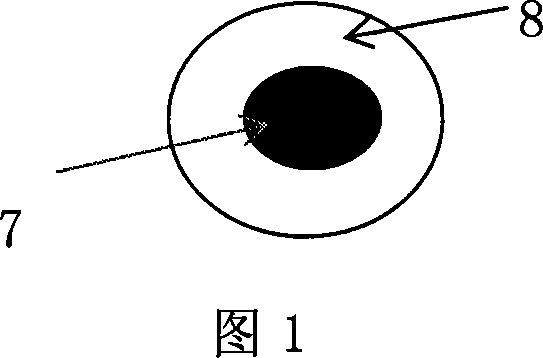

[0033] Prepare the adsorbent material of the present invention as shown in accompanying drawing 1 according to the following steps:

[0034] 1. According to the ratio of the cation exchangeable amount (moles) of sodium bentonite and the molar ratio of quaternary ammonium salts as 1: 1, 44 grams of double hydrogenated tallow dimethyl ammonium chloride (purchased from Boxing China Resources Oil Co., Ltd. Chemical Co., Ltd.) and 53 grams of sodium bentonite (purchased from Zhejiang Fenghong Clay Chemical Co., Ltd.), were added to a three-necked flask, and 300 milliliters of deionized water was added to keep the temperature at 90 ° C, and the mixture was stirred to react for 2 hours , to obtain a slurry product;

[0035] 2. Transfer the prepared slurry product to a beaker, and add 20-30 mesh activated carbon particles (ZJ-238, Jiangsu Liyang South Activated Carbon Factory) into it, so that the activated carbon particles are completely covered by the above slurry;

[0036] 3. Dry ...

Embodiment 2

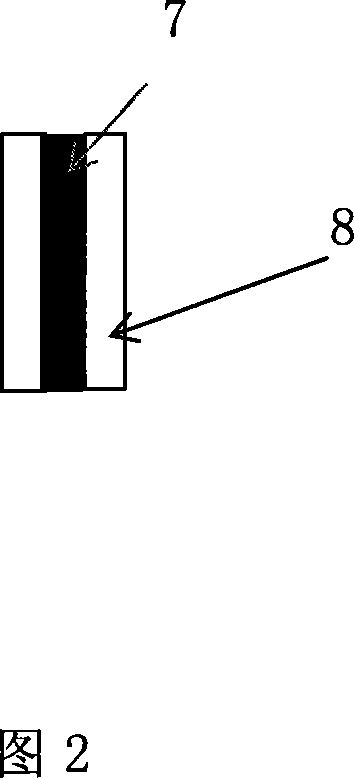

[0039] Prepare the adsorbent material of the present invention as shown in accompanying drawing 2 according to the following steps:

[0040] 1, prepare slurry product according to the operation identical with the step 1 of embodiment 1;

[0041] 2. Use a scraper to evenly coat the prepared slurry product on the upper and lower surfaces of a fibrous activated carbon filter screen (Nantong Senyou Carbon Fiber Co., Ltd.) whose length × width × thickness is 20mm × 10mm × 4mm, so that the above slurry The material is coated on the upper and lower outer surfaces of the sheet-shaped activated carbon;

[0042] 3. Dry the product obtained in step 2 for 4 hours at 130° C. to prepare the layered coated adsorbent material of the present invention.

[0043] The structure of the layered coating form adsorption material of the present invention is as shown in accompanying drawing 2, and it is made of sheet-like activated carbon 7 and the modified mineral material sodium bentonite 8 that is ...

Embodiment 3

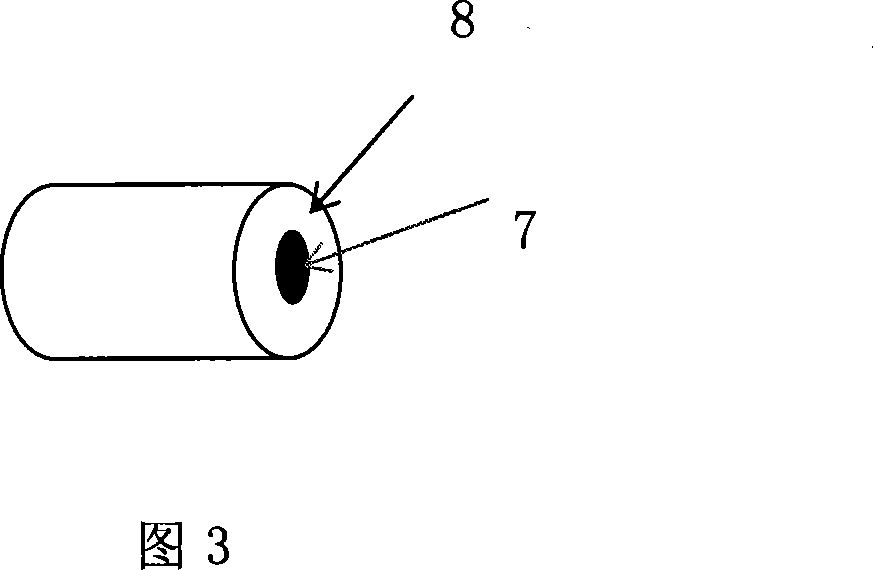

[0045] Prepare the adsorbent material of the present invention as shown in accompanying drawing 3 according to the following steps:

[0046] 1, prepare slurry product according to the operation identical with the step 1 of embodiment 1;

[0047] 2. Use a brush to evenly coat the prepared slurry product on the outer surface of a cylindrical granular activated carbon (Hangzhou Timber Co., Ltd. Activated Carbon Branch 15#A) with a diameter of 4mm and a length of 20mm, so that the above-mentioned slurry is coated on the outer surface of the cylindrical activated carbon;

[0048] 3. Dry the product obtained in step 2 for 4 hours at 130° C. to prepare the column-coated adsorption material of the present invention.

[0049] The structure of the adsorption material in the columnar coating form of the present invention is as shown in accompanying drawing 3, and it is made of the modified mineral material sodium bentonite 8 that is coated on the outside of the cylindrical activated car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com