Multifunctional protection paste for outside wall

A multi-functional, external wall insulation layer technology, applied in the direction of filling slurry, polyurea/polyurethane coating, coating, etc., can solve the problem of large difference in thermal conductivity of the insulation layer, accelerated aging cracks of the protective layer, and large amount of protective mortar layer To achieve excellent multi-crack resistance, reduce the weight of the wall, and make up for cracks in the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A multifunctional protective slurry for exterior walls, consisting of two components A and B, characterized in that it consists of the following raw materials in weight percentage:

[0047] Elastic emulsion 12Kg Cement 21.85Kg

[0048] Cellulose ether 0.15Kg Perlite 30Kg

[0049] Anti-crack fiber 0.1Kg Glass beads 35Kg

[0050] Wood fiber 0.2Kg Dispersant 0.1Kg

[0051] Water reducer 0.5Kg Antifungal agent 0.1Kg;

[0052] Among them, elastic emulsion, cellulose ether, anti-cracking fiber, wood fiber, dispersant, and antifungal agent constitute A component, and cement, perlite, glass microspheres, fly ash, and water reducer constitute B component.

Embodiment 2

[0054] A multifunctional protective slurry for exterior walls, consisting of two components A and B, characterized in that it consists of the following raw materials in weight percentage:

[0055] Elastic emulsion 25Kg Cement 17.75Kg

[0056] Cellulose ether 0.25Kg Perlite 10Kg

[0057] Anti-crack fiber 0.3Kg Glass beads 15Kg

[0058] Wood fiber 0.5Kg Fly ash 30Kg

[0059] Dispersant 0.1Kg Water reducer 1Kg

[0060] Antifungal agent 0.1Kg;

[0061] Among them, elastic emulsion, cellulose ether, anti-cracking fiber, wood fiber, dispersant, and antifungal agent constitute A component, and cement, perlite, glass microspheres, fly ash, and water reducer constitute B component.

[0062] Antifungal agent 0.1Kg;

[0063] Among them, elastic emulsion, cellulose ether, anti-cracking fiber, wood fiber, dispersant, and antifungal agent constitute A component, and cement, perlite, glass microspheres, fly ash, and water reducer constitute B component.

Embodiment 3

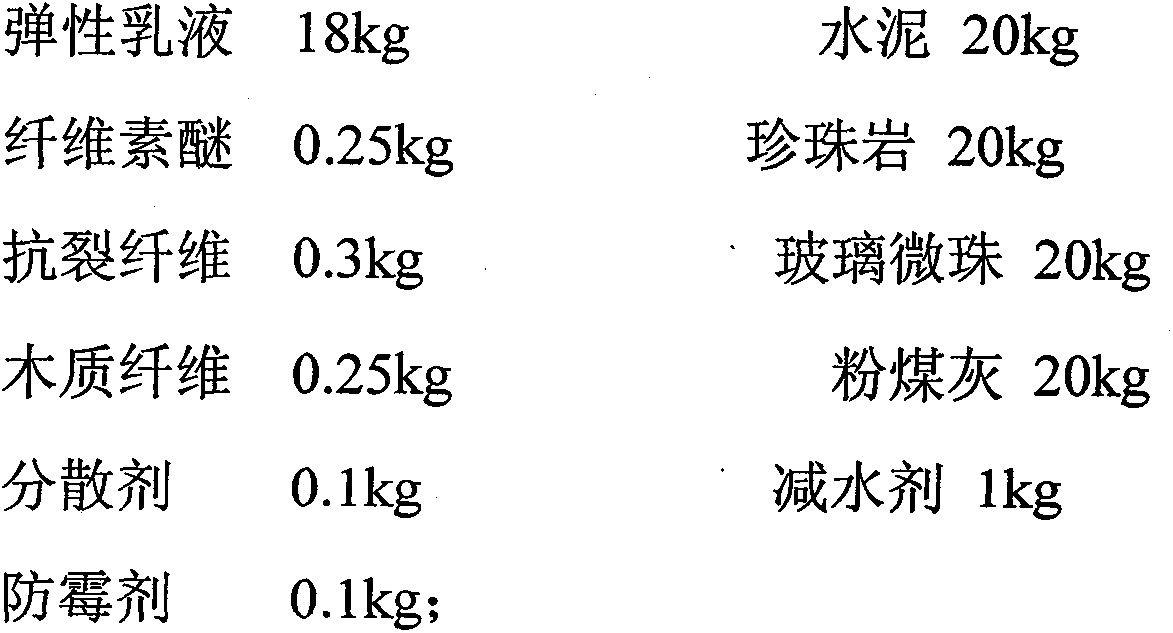

[0065] A multifunctional protective slurry for exterior walls, consisting of two components A and B, characterized in that it consists of the following raw materials in weight percentage:

[0066] Elastic emulsion 18Kg Cement 20Kg

[0067] Cellulose ether 0.25Kg Perlite 20Kg

[0068] Elastic emulsion 18Kg Cement 20Kg

[0069] Cellulose ether 0.25Kg Perlite 20Kg

[0070] Anti-crack fiber 0.3Kg Glass beads 20Kg

[0071] Wood fiber 0.25Kg Fly ash 20Kg

[0072] Dispersant 0.1Kg Water reducer 1Kg

[0073] Antifungal agent 0.1Kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com